Performance Tune

#61

The work was done at ISP who I cannot recommend. I am not sure if I was the first Jaguar or not but had some damage to my car, a disconnected front impact sensor which cost me $175 at Jaguar dealer ship to find out, metal shavings in the engine room. They had huge problems installing the pulley. The shaft has to be heated up until it is hot red with a torch so when the pulley is pressed on it almost fuses with the shaft. it should not be shaved down.

I am not sure I have the AFR numbers in the files they gave me. I have another tuning tool now from Viezu for my XKRS on which i am installung a new manifold back Milltek exhaust and see if I can capture some AFR numbers there before we start tuning. The XKRS has lost all the overrun. I will definitely record them on the FType in January when I have the new exhaust installed and reflash the car. I have to look at the files at home to see if they include the AFR numbers or just hp and torque.

The power is undeniable though, the car pulls like crazy, it gained over 100hp at the wheel.

I am not sure I have the AFR numbers in the files they gave me. I have another tuning tool now from Viezu for my XKRS on which i am installung a new manifold back Milltek exhaust and see if I can capture some AFR numbers there before we start tuning. The XKRS has lost all the overrun. I will definitely record them on the FType in January when I have the new exhaust installed and reflash the car. I have to look at the files at home to see if they include the AFR numbers or just hp and torque.

The power is undeniable though, the car pulls like crazy, it gained over 100hp at the wheel.

The following users liked this post:

Foosh (11-12-2015)

#62

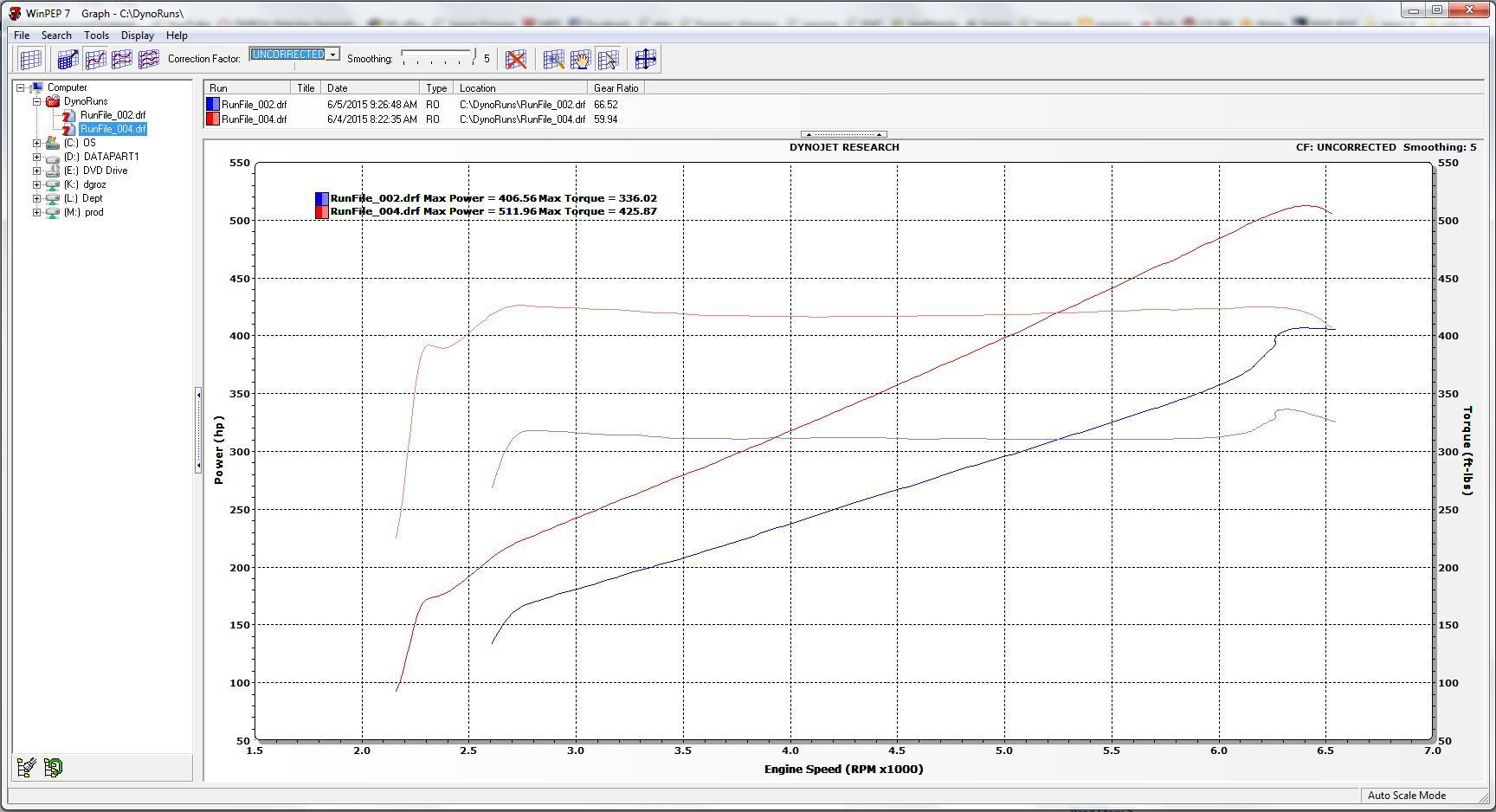

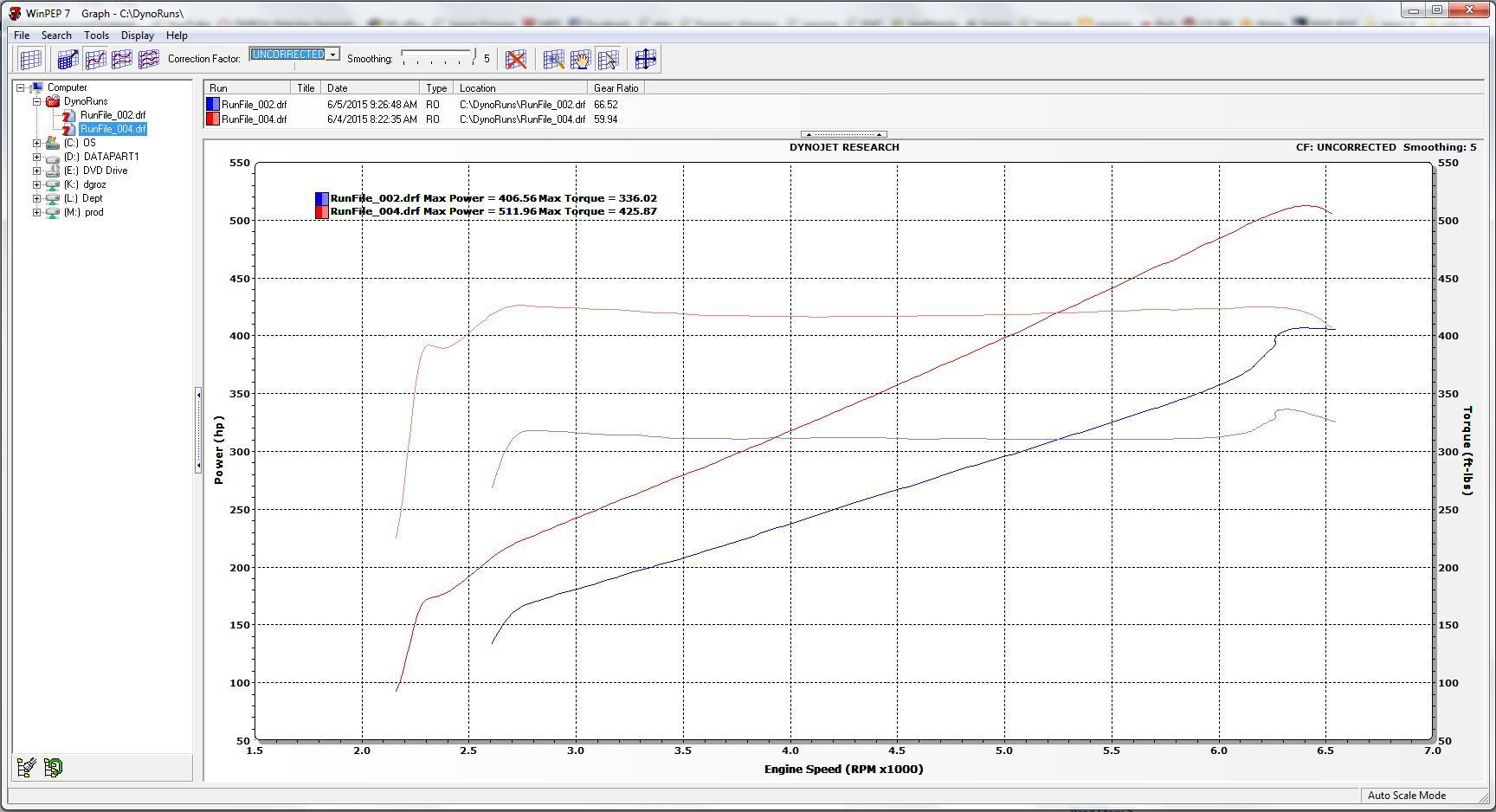

Here is my dyno sheet of my 2014 V8S with pulley and Eurocharged tune ...

It is running lean as you can hear some of the over run does not make it out of the exhaust but I have a new exhaust coming in January and will have it tuned richer then.

It ended up putting more power down on the same dyno as my pulley tuned XKRS which ended up at 500whp.

It is running lean as you can hear some of the over run does not make it out of the exhaust but I have a new exhaust coming in January and will have it tuned richer then.

It ended up putting more power down on the same dyno as my pulley tuned XKRS which ended up at 500whp.

#63

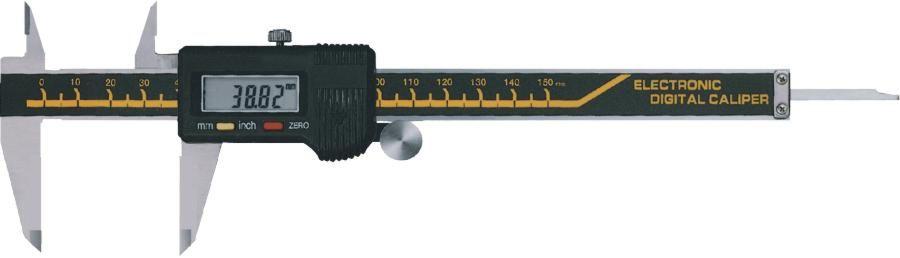

Do you still have your old pulley? I would be interested in measuring the pitch diameter of the OEM pulley from a V8.

#65

Heating the shaft is totally illogical, none of the pulley suppliers have ever instructed to do that.

I would say it's pretty likely.

#66

#67

Maybe the reason they had such huge problems is that the pulley needs to be heated, not the shaft. ASM in Hanover used a heating coil to heat the pulley to over 500 degF, and it slid on easily.

Do you still have your old pulley? I would be interested in measuring the pitch diameter of the OEM pulley from a V8.

Do you still have your old pulley? I would be interested in measuring the pitch diameter of the OEM pulley from a V8.

#70

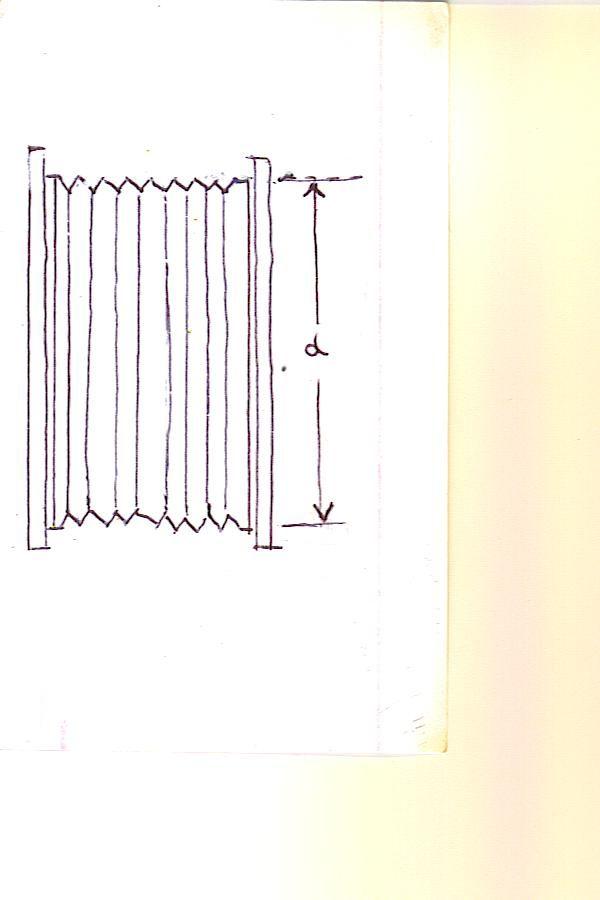

Measure the diameter from the top of the ridges to the top of the ridges

Formerly lhoboy

#72

Thank you!

OEM V8 pulley diameter = 65mm

OEM V6 pulley diameter = 62mm

Aftermarket pulley diameter = 60.5mm (smallest that can fit over shaft housing).

Results in a 7% reduction for the V8 and 2.5% reduction for the V6. Compare this to the 13-18% reduction pulleys we were installing on the R53 MINIs. Any significant power gain will have to come from the tune.

OEM V8 pulley diameter = 65mm

OEM V6 pulley diameter = 62mm

Aftermarket pulley diameter = 60.5mm (smallest that can fit over shaft housing).

Results in a 7% reduction for the V8 and 2.5% reduction for the V6. Compare this to the 13-18% reduction pulleys we were installing on the R53 MINIs. Any significant power gain will have to come from the tune.

Last edited by Unhingd; 11-15-2015 at 06:10 AM.

The following users liked this post:

Foosh (11-15-2015)

#73

If I were measuring, I'd easily be off by 3mm or more trying to figure out where the top of the ridges are from the outside of the pulley.

Isn't it likely that they are the same size? I can't imagine why they'd go to all the trouble of stocking two different parts for such a small difference (1/8").

Isn't it likely that they are the same size? I can't imagine why they'd go to all the trouble of stocking two different parts for such a small difference (1/8").

#74

#75

I used two straight edges placed across the bottom and top of the pulley tracks. they were then lined up as parallel as possible and then measured at 65 mm. Yes, it was eye balled but it is extremely close to accurate.

BTW, I, regarding the installation of the performance pulleys, I learned there are 3 different manufacturer of superchargers that were outsourced for the F Type. On one of the suppliers, the housing where the pulley is has to be filled down in order to accept the smaller performance pulley. As luck would have it, mine has one such SC. It is minimal filling but it has to done to fit.

BTW, I, regarding the installation of the performance pulleys, I learned there are 3 different manufacturer of superchargers that were outsourced for the F Type. On one of the suppliers, the housing where the pulley is has to be filled down in order to accept the smaller performance pulley. As luck would have it, mine has one such SC. It is minimal filling but it has to done to fit.

#76

BTW, I, regarding the installation of the performance pulleys, I learned there are 3 different manufacturer of superchargers that were outsourced for the F Type. On one of the suppliers, the housing where the pulley is has to be filled down in order to accept the smaller performance pulley. As luck would have it, mine has one such SC. It is minimal filling but it has to done to fit.

#77

Please understand that I was not suggesting you weren't extremely close. My point was that 3mm is extremely close, particularly when you're trying to eyeball where the ridges start at the top and bottom and measuring with a straight-edge. I know the V6 and V8 superchargers are the same manufacturer, and I was under the impression that they both had the same model supercharger, but I don't know that for sure.

#78

I used two straight edges placed across the bottom and top of the pulley tracks. they were then lined up as parallel as possible and then measured at 65 mm. Yes, it was eye balled but it is extremely close to accurate.

BTW, I, regarding the installation of the performance pulleys, I learned there are 3 different manufacturer of superchargers that were outsourced for the F Type. On one of the suppliers, the housing where the pulley is has to be filled down in order to accept the smaller performance pulley. As luck would have it, mine has one such SC. It is minimal filling but it has to done to fit.

BTW, I, regarding the installation of the performance pulleys, I learned there are 3 different manufacturer of superchargers that were outsourced for the F Type. On one of the suppliers, the housing where the pulley is has to be filled down in order to accept the smaller performance pulley. As luck would have it, mine has one such SC. It is minimal filling but it has to done to fit.

#79

Please understand that I was not suggesting you weren't extremely close. My point was that 3mm is extremely close, particularly when you're trying to eyeball where the ridges start at the top and bottom and measuring with a straight-edge. I know the V6 and V8 superchargers are the same manufacturer, and I was under the impression that they both had the same model supercharger, but I don't know that for sure.