Ball Joint Press

#1

I have been doing a lot of reading on this site about replacing ball joints and bushings. Often the process requires a press, something I don't own right now. I have done a little research and found several choices at various sites online, the following are from Harbor Freight, not because I recommend (or not) getting it there, it's just an easy site to navigate.

I found three or four choices that I want to post here and see what others here recommend.

1. C-Clap style: Ball Joint Press Kit This one seems like the hardest to use but the easiest to store away for those of us who aren't going to do a lot of pressing. At $59.99 it comes with some attachments, don't know if they're the onese I'd need or not, though.

2. Arbor Press: 1 Ton Arbor Press & Other Arbor Presses - Harbor Freight Tools I am wondering if the clearance allows enough room to work on ball joints. Also, it appears that this one should be attached to a work bench -- I don't have a work bench. On sale for $47.99 for the 1 ton, $3499 for the 1/2 ton.

3. Floor stand model: 1 Ton Arbor Press & Other Arbor Presses - Harbor Freight Tools Because it's a bit pricier at $129.99 (sale price), and since it probably needs to be bolted to the floor, this is probably not my best bet for an occasionally used press.

I found three or four choices that I want to post here and see what others here recommend.

1. C-Clap style: Ball Joint Press Kit This one seems like the hardest to use but the easiest to store away for those of us who aren't going to do a lot of pressing. At $59.99 it comes with some attachments, don't know if they're the onese I'd need or not, though.

2. Arbor Press: 1 Ton Arbor Press & Other Arbor Presses - Harbor Freight Tools I am wondering if the clearance allows enough room to work on ball joints. Also, it appears that this one should be attached to a work bench -- I don't have a work bench. On sale for $47.99 for the 1 ton, $3499 for the 1/2 ton.

3. Floor stand model: 1 Ton Arbor Press & Other Arbor Presses - Harbor Freight Tools Because it's a bit pricier at $129.99 (sale price), and since it probably needs to be bolted to the floor, this is probably not my best bet for an occasionally used press.

#2

Hi Mike the c clamp press is the exact unit i used. I did the work at work so I had my coworker help me realignment of the press. It's small enough to easily store away in the case but the opening in the clamp is large enough to fit any job you need to do on suspension (I think!!). On the threaded shaft of the c clamp there is a removable tip. With the tip removed the hollow threaded shaft gives enough room for the threaded ball joint end to travel into. Just remember to shim away the c clamp so the ball joint bottoms before the c clamp does. I made my own shims and added them to the kit.

#3

I opted for the c-clamp ball joint press, but did not go with Harbor Freight. I looked at the HF one and thought it was poor quality. I went with the OTC c-clamp ball joint press.

Just searched and this is far less than I paid: OTC 7249 Ball Joint Service Tool Set

I just got an email from my stepdad who's overseas and he sent me a link for snap-on's newest c-clamp ball joint press. Watch this: Snap-on Tools Master Ball Joint Press Set - YouTube

Every feature the snap-on has I was cussing I didn't have when replacing the ball joints on my '00 F350 PSD and '86 F250 IDI. I could have spent $300 more (per the price I paid for the OTC kit plus the Ford kit) for the snap-on kit and saved hours of work. Oh well.

BTW, that arbor press won't have enough umph to remove ball joints and maybe not enough to install them. I have a 5-ton arbor press and I don't think it would even work.

Just searched and this is far less than I paid: OTC 7249 Ball Joint Service Tool Set

I just got an email from my stepdad who's overseas and he sent me a link for snap-on's newest c-clamp ball joint press. Watch this: Snap-on Tools Master Ball Joint Press Set - YouTube

Every feature the snap-on has I was cussing I didn't have when replacing the ball joints on my '00 F350 PSD and '86 F250 IDI. I could have spent $300 more (per the price I paid for the OTC kit plus the Ford kit) for the snap-on kit and saved hours of work. Oh well.

BTW, that arbor press won't have enough umph to remove ball joints and maybe not enough to install them. I have a 5-ton arbor press and I don't think it would even work.

Last edited by mechelement; 05-20-2012 at 10:54 PM.

#4

If your pressing in/out of aluminium suspension components, try pouring some boiling water over the aluminium before pressing. Aluminium has a very high coefficient of expansion and this should cause it to relinquish some of its 'grip' on the steel ball joint which has a much lower value.

#6

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,408

Likes: 0

Received 3,901 Likes

on

3,205 Posts

I have always used the C-Clamp style on my vehicles. I don't think the others would work unless you removed the lower control arm from the vehicle. Sounds like lots more work that it is worth.

Granted, I normally only use the press to seat the ball joints. I have a tendency to use a BFH (3 pounder) to smack the ball joints out of the vehicle. I just put a jack under the lower control arm to prevent it from any downward motion. From there, few good whacks and out it pops. So much easier than trying to get the press to push it out. if you are worried about damaging the control arm, you take the few few whacks to get it moving, then once it is about flush, you add a large socket on top and another whack or two and out it pops.

When using the C-Clamp style, a good impact wrench is great to use too. Makes it pop right in there.

Granted, I normally only use the press to seat the ball joints. I have a tendency to use a BFH (3 pounder) to smack the ball joints out of the vehicle. I just put a jack under the lower control arm to prevent it from any downward motion. From there, few good whacks and out it pops. So much easier than trying to get the press to push it out. if you are worried about damaging the control arm, you take the few few whacks to get it moving, then once it is about flush, you add a large socket on top and another whack or two and out it pops.

When using the C-Clamp style, a good impact wrench is great to use too. Makes it pop right in there.

#7

Trending Topics

#9

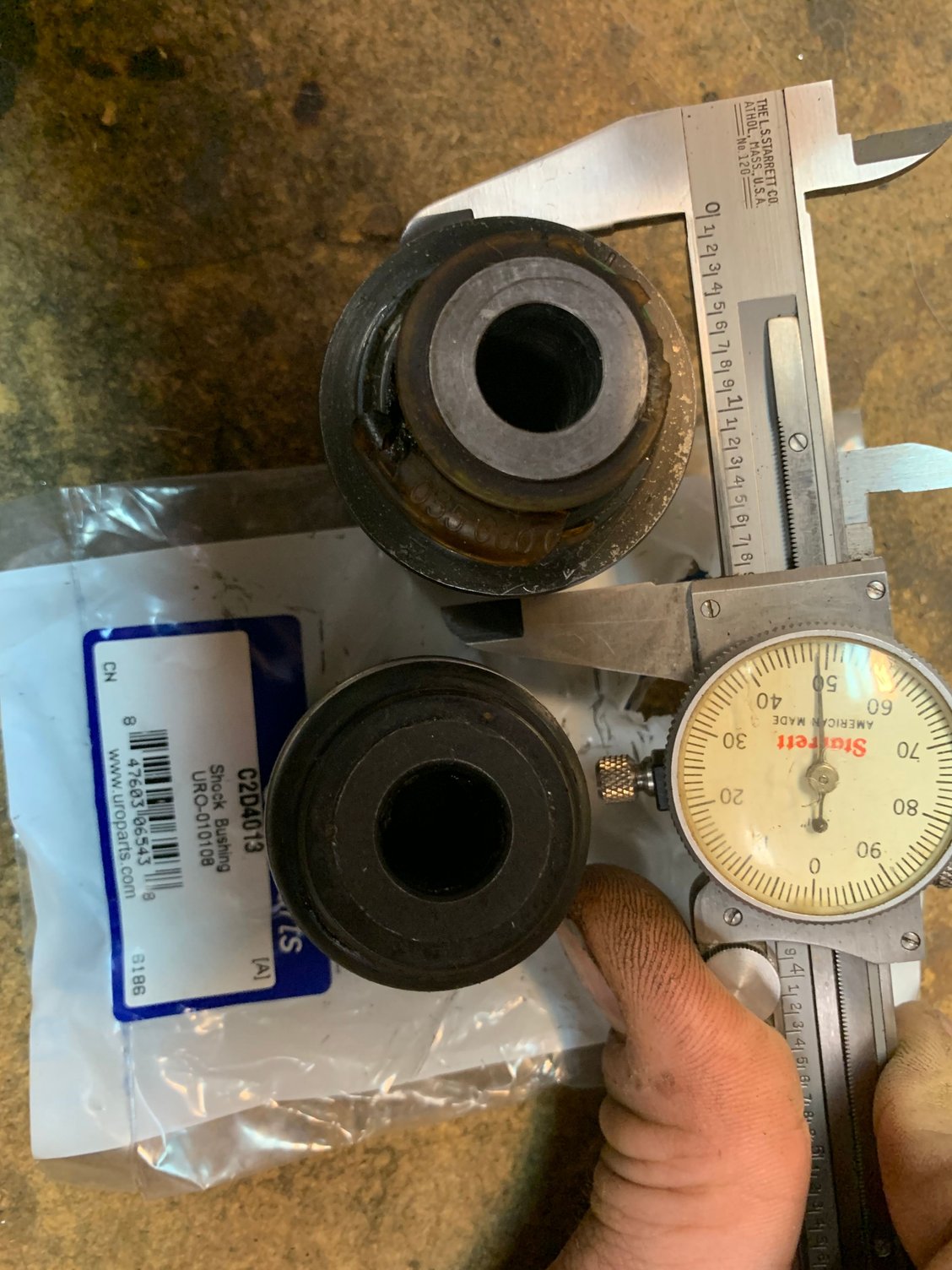

I made the plung and picked up the OTC press and used it to do the lower strut bushing. The original press rings didn't come close to fitting the bushing so I cut some steel pipe to do the correct press work. Now I have an additional three press rings. There is no substitute for the right tool to do the job in the best possible way.

#10

I made the plung and picked up the OTC press and used it to do the lower strut bushing. The original press rings didn't come close to fitting the bushing so I cut some steel pipe to do the correct press work. Now I have an additional three press rings. There is no substitute for the right tool to do the job in the best possible way.

#11

I used a one inch socket to press out the strut bushing and used a 50 mm piece of pipe as the reciever to drive into. After I removed the old bushing I striped it down and used the outer ring that I ground about a mm from the side of one end so that after I used it to press I could remove it from the strut other wise it would be locked in. What I noticed is that the ring on the strut end is welded on out of center that is so when you press in the bushing and bottom it out on the ring from the short side( the side closer to center) it puts the bushing into perfect center with the strut. Study the semitery of the welded ring and it will make sence. To use the original bushing outer ring to drive in the new one you need to remove the outer retaining ring on the new rubber boot pull the boot off the inner sleeve so that it will collapse out of the way of your press ring other wise you will cut the rubber boot on your new bushing. And of cousre lock tite. Pressing the bushing is the easy part. The sent up is what counts.

#12

#13

The following 2 users liked this post by GGG:

motorcarman (01-11-2020),

NBCat (11-21-2019)

#14

yes old thread but still good info.

I had a chance to use this tool this weekend and it worked well. But it really needs some specific sized pushers. I used a socket I had for rear balljoints but I was lucky I had a good sized socket.

The following users liked this post:

GGG (01-11-2020)

#15

I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100.

. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100.

. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

#16

In years past I'd used sockets, but I've sure busted a bunch of sockets on rusty bolts with a cheater bar so that kind of scares me a little about using sockets in a press. Sockets seem to "fracture" when they break. They don't bend so I doubt one would just "crush" under a press. I don't want a socket fragment flying at me or a control arm falling on my toe, or even just getting the &#%$ scared out of me when it gives way.  I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100. https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100. https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100. https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

I've got a c-clamp style "ball joint" kit much like the snap-on pictured, but a no-name brand. Despite being "universal", it doesn't seem to fit hardly anything, at least not that I've worked on. Much more useful I've found is a set of press sleeves in 2mm increments like this one on Amazon for $100. https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1. I just use the sleeves with my shop press. The walls of the sleeves are very thick and I don't worry about them breaking. I'm certain the car parts that I'm working on would sooner break under pressure than these sleeves.

#17

Major auto parts stores offer loaner tools you can use for free.

For example:

https://www.autozone.com/loan-a-tool...ece/449947_0_0

For example:

https://www.autozone.com/loan-a-tool...ece/449947_0_0

Thread

Thread Starter

Forum

Replies

Last Post

Camnelson324

S-Type / S type R Supercharged V8 ( X200 )

3

09-27-2015 08:48 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)