How to Measure the Rear Springs.

#1

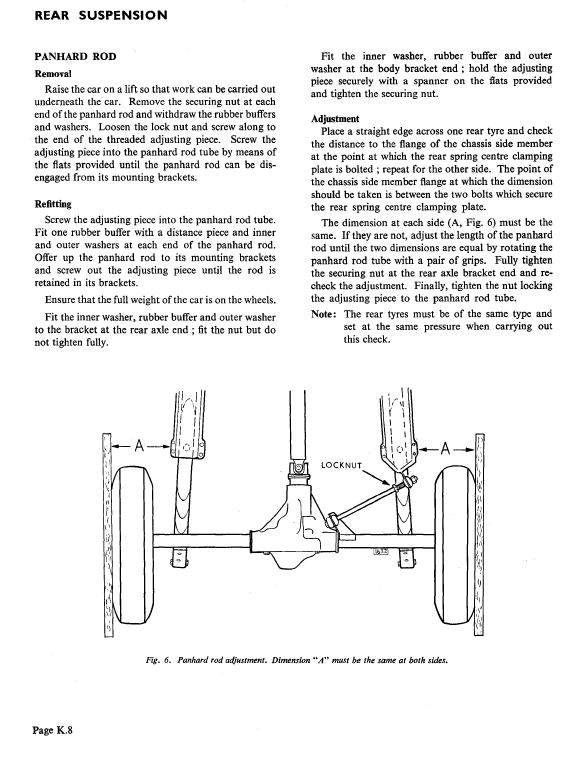

I have a 1962 Mk 2 that while I'm doing rear suspension work on, I wanted to check out the springs. The factory service manual has a drawing showing how to take a measurement to see if the springs are within specs. My question is are you to take the measurement on a bare main spring or the complete spring assembly? The drawing just shows the main spring.

#2

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

#3

Thanks for your reply, Glyn. What I'm trying to find out is about the arch of the springs. The drawing in the factory service manual shows a line drawn from the center of the rear bolt hole of the main spring to the flat on the opposite end of the spring. In the drawing it just shows the main spring leaf only and not a complete spring assembly. So, my question is do I need to take the springs apart and measure just that main leaf or measure a complete spring assembly? I have never driven this car and don't know if the springs need to be re-arched.

#4

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

#5

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

#6

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

#7

I really don't have any reason to believe that any parts were mismatched or buggered up. I don't think the springs have ever been taken apart before. I tend to believe that the drawing means that the measurement be taken on a complete spring assembly and not just the one leaf. I would like to be sure.

The following users liked this post:

Glyn M Ruck (07-11-2023)

Trending Topics

#8

Join Date: Nov 2012

Location: Joyner, Queensland, Australia

Posts: 936

Received 1,040 Likes

on

605 Posts

I have measured this free camber a number of times with the springs apart and have never found a spring out of tolerance.

I now consider it a WOFTAM (a Waste Of Flaming Time and Money)

The critical parts in the rear end of MK1/2 are the rubbers.

If the rear end is sagging it will be the body mount rubbers, particularly the front mount pad and centre mount rubber.

The really critical parts for handling are the torque arm rubbers.

The torque arms keep the axle located correctly to the body. Bad rubbers will allow the axle to wander.

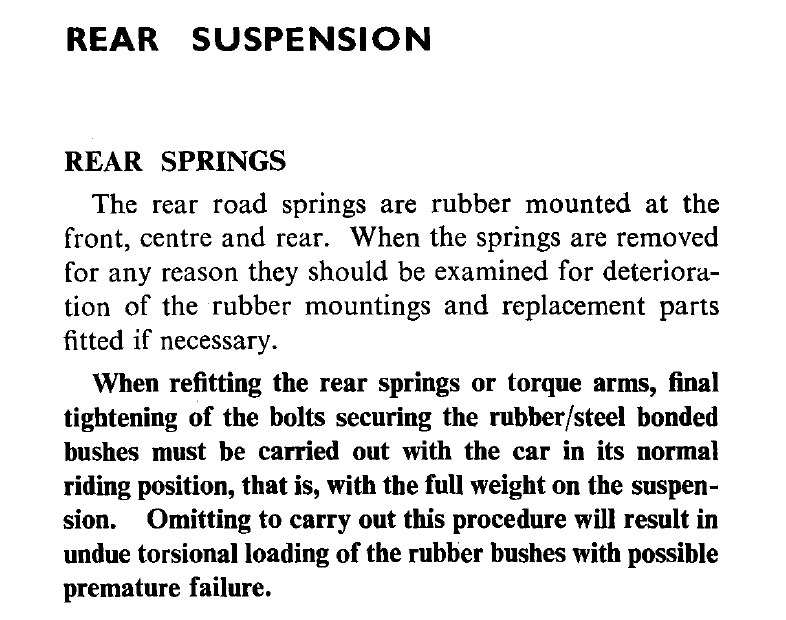

The panhard rod system does work but do check its body end mount for cracks etc. A very common fault

I now consider it a WOFTAM (a Waste Of Flaming Time and Money)

The critical parts in the rear end of MK1/2 are the rubbers.

If the rear end is sagging it will be the body mount rubbers, particularly the front mount pad and centre mount rubber.

The really critical parts for handling are the torque arm rubbers.

The torque arms keep the axle located correctly to the body. Bad rubbers will allow the axle to wander.

The panhard rod system does work but do check its body end mount for cracks etc. A very common fault

The following users liked this post:

Glyn M Ruck (07-11-2023)

#9

Thanks for the advice. I took one of the springs apart and the main leaf by itself is out of tolerance. The spring assembled was within tolerance. I didn't find any cracks around the Panhard rod body mount but, I went ahead and braced it up anyway. The rod itself was bent, which I've read is common. I got the rod straight within.010." I found and repaired cracks in the body around the right-side upper shock mount and on the left side fender well where the exhaust mounts. I have all new poly bushings for all the rear suspension. All of the OEM bushings and mounts were shot. I really don't know if the car was sagging or not. It had been in storage for 20 years and the tires barely held air long enough to get it up on a trailer. I'm not going to do a concours type restoration on car but, while I'm this far into it I'm going to tear down, bead blast, and paint the springs.

The following users liked this post:

Glyn M Ruck (07-11-2023)

#10

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

Thanks Bill ~ I was hoping you would chime in. You know Mk1 & Mk2 backwards. There is a factory bulletin to dealers to reinforce the Panhard rod mounting to the body. On early cars (Mk1) it used to pull right out of the body. They were still learning weak spots in the monocoque bodywork. I have it somewhere but too much trouble to find (my filing system sucks). We know about it and that's all that matters.

Last edited by Glyn M Ruck; 07-11-2023 at 04:16 AM.

#11

The following users liked this post:

Glyn M Ruck (07-11-2023)

#12

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,361

Received 1,437 Likes

on

1,113 Posts

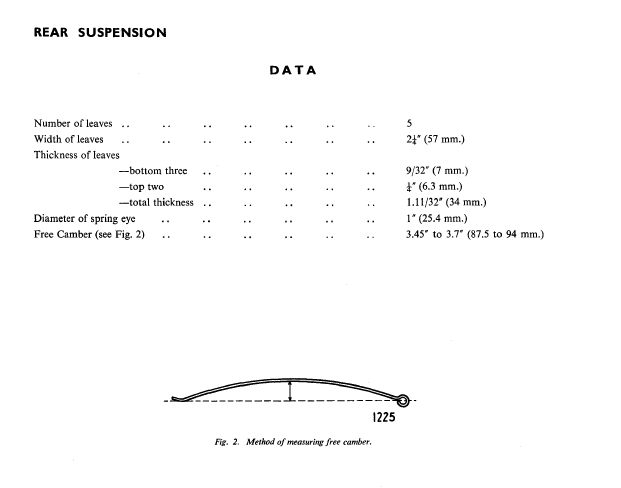

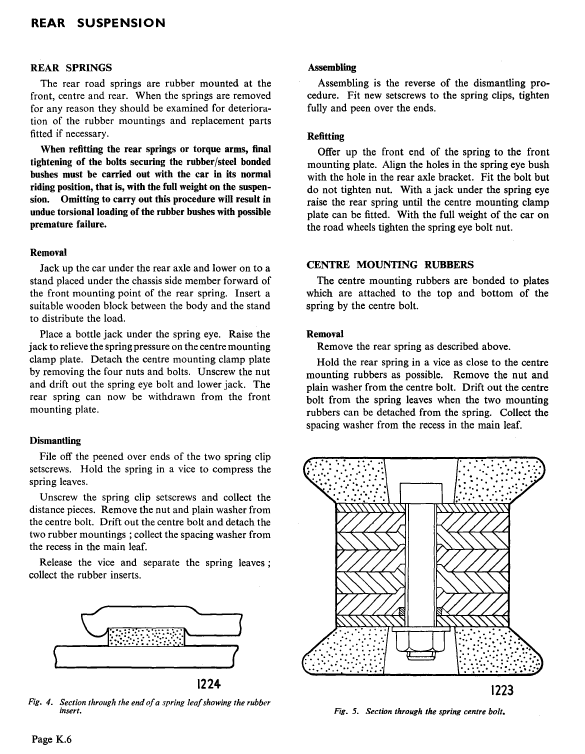

#13

To add to Bill's comment on rubber, the rubber pads between the leaves of the spring are important in maintaining the set of the assembled spring. They deteriorate and disappear. The centre support of the spring on the left side of the car (without the Panhard rod mount) can collapse and cause the car to sit low on that corner. I've modified the one that will go on my car so that it is a mirror image of the one on the right side. The whole arrangement of the spring hangers is a terrible mud trap and suffers corrosion damage. The design of the rear suspension of the Mk2 is clever in many ways, even brilliant compared with what most were doing in the mid-1950s, but it has its weaknesses.

The following users liked this post:

Glyn M Ruck (07-11-2023)

#14

One thing I found after taking the right-side spring apart was it is arched .125" more than the left spring. After both springs are reassembled the one with the most arch will be installed on the left side. Does anyone know of a source for the rubber buttons that go between the leaves of the spring? If I don't find them for sale somewhere I'm going to look into buying a do-it-yourself poly bushing kit. I can machine a mold then and cast them myself. Thanks for all the help everyone.

The following users liked this post:

Glyn M Ruck (07-12-2023)

#15

I think that I cut the buttons out of some rubber sheet. It was a long time ago.

If the car doesn't sit level and you are fairly sure it's due to the rear springs, it's possible to make some adjustments at the reaction plate (the opposite end of the spring from the axle). Add a spacer between the plate and the spring to raise the car or washers between the plate and the body to lower it. Don't do anything until the springs have settled as leaf springs have a lot of internal friction to shake down.

If the car doesn't sit level and you are fairly sure it's due to the rear springs, it's possible to make some adjustments at the reaction plate (the opposite end of the spring from the axle). Add a spacer between the plate and the spring to raise the car or washers between the plate and the body to lower it. Don't do anything until the springs have settled as leaf springs have a lot of internal friction to shake down.

The following 2 users liked this post by Peter3442:

Bill Mac (07-12-2023),

Glyn M Ruck (07-12-2023)

#16

I noticed that SNG Barratt has a lot of rear suspension rubber and poly bits, they may have the button spacers. Also David Manners has complete springs that look as though they could be some of the factory original stock that he bought 50 years ago.

Last edited by Peter3442; 07-12-2023 at 09:10 AM.

The following users liked this post:

Glyn M Ruck (07-12-2023)

#17

Join Date: Nov 2012

Location: Joyner, Queensland, Australia

Posts: 936

Received 1,040 Likes

on

605 Posts

Other small snippets of information ref. MK1/MK2 rear springs.

Many years ago, I got our local MK1&MK2 Jag club members to check the rear end "ride height" of their cars.

This was done on the basis of nobody in the car and the distance was from the centre of the boot (trunk) lock to the ground. We ignored the fuel quantity which could vary by 70 lbs.

The average turned out to be 18 1/2 to 19 inches.

One of my MK1s came out at 16 inches and was "dragging its bum" so it did require attention.

If you see a scrape mark on the rear cover of the differential it means that the axel is moving around and is a sure sign of torque arm bushes being "shot" and the diff rubbing onto the car body.

I have seen this on 4 cars and on one car had worn a hole in the diff cover requiring a welded patch repair.

Many years ago, I got our local MK1&MK2 Jag club members to check the rear end "ride height" of their cars.

This was done on the basis of nobody in the car and the distance was from the centre of the boot (trunk) lock to the ground. We ignored the fuel quantity which could vary by 70 lbs.

The average turned out to be 18 1/2 to 19 inches.

One of my MK1s came out at 16 inches and was "dragging its bum" so it did require attention.

If you see a scrape mark on the rear cover of the differential it means that the axel is moving around and is a sure sign of torque arm bushes being "shot" and the diff rubbing onto the car body.

I have seen this on 4 cars and on one car had worn a hole in the diff cover requiring a welded patch repair.

The following 2 users liked this post by Bill Mac:

Glyn M Ruck (07-13-2023),

Peter3442 (07-13-2023)

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)