Panhard Rod. (ensure no mounting point damage ~ they are famous for that,)

#1

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

The following users liked this post:

Peter3442 (09-06-2022)

#2

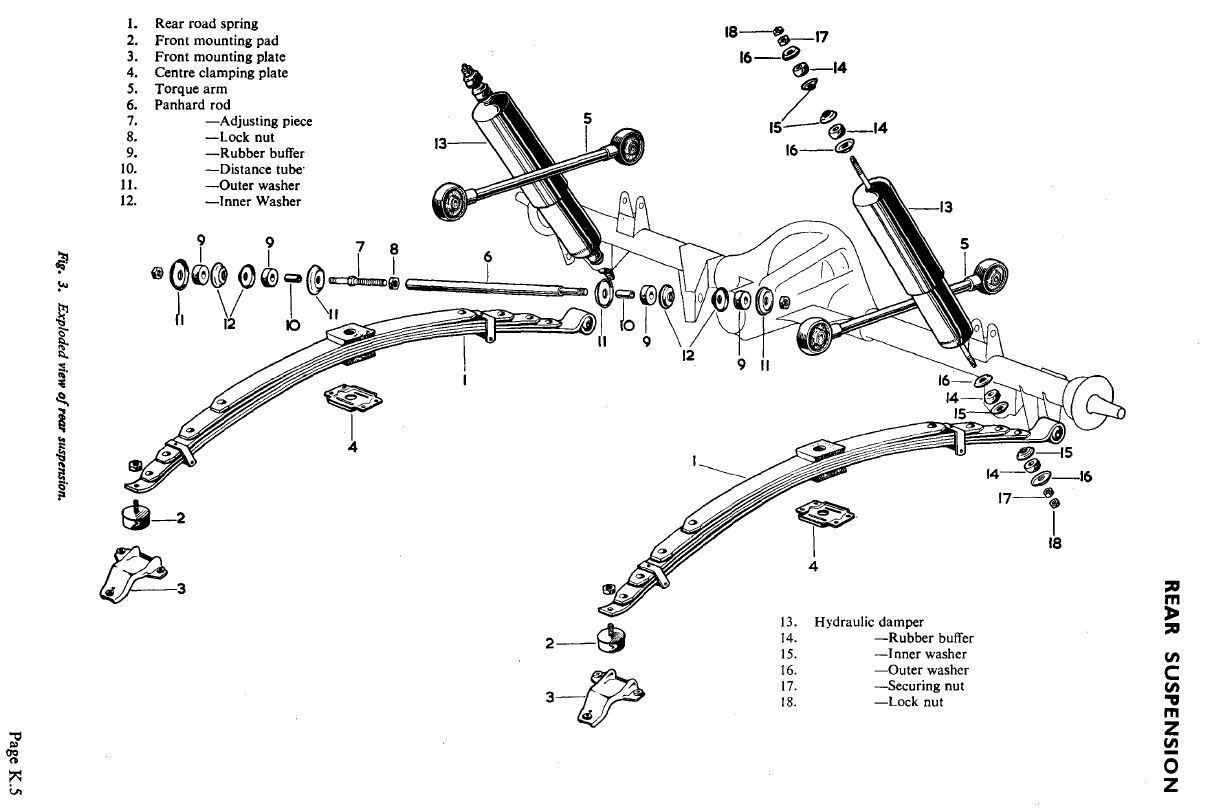

The rod and its mounting at the body end are heavily loaded. The mounting was progressively strengthened over the years. The one on my 1963 car was intact when I took the car apart in spite of fairly severe corrosion and a hard life (that included a bent axle shaft). The Panhard rod itself had a bend in it in the threaded section at the body end. This may have been caused or exacerbated by the distance pieces (items 10 in the drawing) being missing. They may prevent over tightening that will limit flexibility of the joints. I bought a replacement rod assembly which turned out to have different rubbers and cups from the original. In addition, it didn't fit the hole in the newly welded in mount to the body. I don't recall which part was incorrect (it was just before the restoration stalled 30 years ago).

The standard Mk2 Panhard rod arrangement is not a great piece of design. A double rod or the multi-link scheme on the (very expensive) coil conversions are undoubtedly better.

The standard Mk2 Panhard rod arrangement is not a great piece of design. A double rod or the multi-link scheme on the (very expensive) coil conversions are undoubtedly better.

The following users liked this post:

Glyn M Ruck (09-05-2022)

#3

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

Thanks for starting some content. I opened the thread for DaveinG. I considered a Mk2 until I took one around the Kyalami race track vs the S Type and that very quickly made up my mind for me. The rear end of the Mk2 is positively crude vs the IRS.. I come from a long string of Alfas that do relatively simple very well. As you know my first choice was a DB6 but I could not find one at a restoration price. If you are going to rebuild the car ground up you don't want to pay too much for it. I should have just stored that Short Chassis Volante until I could afford to restore it.

Last edited by Glyn M Ruck; 09-06-2022 at 05:30 AM.

#4

Join Date: Nov 2012

Location: Joyner, Queensland, Australia

Posts: 960

Received 1,068 Likes

on

626 Posts

The Panhard rod is a bit of a problem, but those torque arms (part 5 in Glyn's diagram) are a real problem in MK1/2 cars.

If the rear end is "wobbly" it is almost for sure it is torque arm bushes.

Putting MK1/2 s on the hoist it is not unusual to see daylight through the bush where the rubber has completely decayed

I don't know how many I have rebuilt or replaced over the years. I actually have a spare pair sitting in my shed ready to go.

I have seen them so bad that the rear of the differential cover has been scraping against the body.

Cheers

If the rear end is "wobbly" it is almost for sure it is torque arm bushes.

Putting MK1/2 s on the hoist it is not unusual to see daylight through the bush where the rubber has completely decayed

I don't know how many I have rebuilt or replaced over the years. I actually have a spare pair sitting in my shed ready to go.

I have seen them so bad that the rear of the differential cover has been scraping against the body.

Cheers

The following 2 users liked this post by Bill Mac:

Glyn M Ruck (09-06-2022),

Peter3442 (09-06-2022)

#5

#6

I can't find my old ones to examine. I've checked my workshop manual and it's vague. It does say to assemble two washers, one rubber buffer and a distance piece on each end of the rod before fitting. My expectation is that the distance piece should go through both rubber buffers, the two washers closest to the body or axle bracket, and the body/axle bracket. Otherwise, I don't see any point in its presence. I presume that its main function is to prevent over compression of the rubber buffers.

#7

Trending Topics

#8

#9

If it goes through the middle of both rubber buffers then it shouldn't be visible. Looking at your photos, there's space for it.

#10

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

The Panhard rod is a bit of a problem, but those torque arms (part 5 in Glyn's diagram) are a real problem in MK1/2 cars.

If the rear end is "wobbly" it is almost for sure it is torque arm bushes.

Putting MK1/2 s on the hoist it is not unusual to see daylight through the bush where the rubber has completely decayed

I don't know how many I have rebuilt or replaced over the years. I actually have a spare pair sitting in my shed ready to go.

I have seen them so bad that the rear of the differential cover has been scraping against the body.

Cheers

If the rear end is "wobbly" it is almost for sure it is torque arm bushes.

Putting MK1/2 s on the hoist it is not unusual to see daylight through the bush where the rubber has completely decayed

I don't know how many I have rebuilt or replaced over the years. I actually have a spare pair sitting in my shed ready to go.

I have seen them so bad that the rear of the differential cover has been scraping against the body.

Cheers

Last edited by Glyn M Ruck; 09-06-2022 at 10:05 AM.

#11

It's absolutely vital that the 'ear' of the rod mount has suitable reinforcement above and below. It's just visible in Dave's photos. The piece above the ear is in the form of a triangular fishplate. It has to be added to modern repair mounts. I think the modern repair mounts are generally made with thicker steel than originals, but have horrible pointed cut outs that will cause them to fatigue in no time without reinforcement. The fishplate should itself be stiffened by a pyramid shaped piece that runs up into the slender chassis rail. Given all that, the mount shouldn't fail.

Rear suspension with a live axle is a complicated compromise. Jaguar wanted to avoid taking loads into the unibody anywhere behind the line of the axle, isolate the body from the differential, minimise axle tramp, and maintain comfort and handling in what is (or was for the time) a heavy, powerful car. For a design from the early 1950s, they didn't do too bad, certainly no worse than Rover with the SD1 30 years later. Keep in mind that the Rovers that won touring car races in the 1980s had their standard rear ends replaced with A-frames (the mystery is how Walkinshaw got that homologated), which brought them into line with various Alfa, Lotus, old Riley, and the modern Mk2 coil upgrades. Not that the coil spring upgrades are perfect. With 6 rods, they're not strictly a mechanism. There's fight in the system such that roll motion relies on flexibility in the bushes.

Rear suspension with a live axle is a complicated compromise. Jaguar wanted to avoid taking loads into the unibody anywhere behind the line of the axle, isolate the body from the differential, minimise axle tramp, and maintain comfort and handling in what is (or was for the time) a heavy, powerful car. For a design from the early 1950s, they didn't do too bad, certainly no worse than Rover with the SD1 30 years later. Keep in mind that the Rovers that won touring car races in the 1980s had their standard rear ends replaced with A-frames (the mystery is how Walkinshaw got that homologated), which brought them into line with various Alfa, Lotus, old Riley, and the modern Mk2 coil upgrades. Not that the coil spring upgrades are perfect. With 6 rods, they're not strictly a mechanism. There's fight in the system such that roll motion relies on flexibility in the bushes.

The following users liked this post:

Glyn M Ruck (09-07-2022)

#12

The distance piece goes all the way through and as mentioned above is to stop the bushes from being totally compressed.

In the picture above you appear to be missing the inner and outer washer, the make up in total should be:

Thick washer

Rubber bush

Thin washer

Body panhard rod mount

Thin washer

Rubber bush

Thick washer

Nut

With the distance pice going through the parts above in red.

I'm interested in the comment above about fixed length panhard rods, what cars were these on as my 1959 MK2 has an adjustable one? I can't see how they would have adjusted the rear suspension with a fixed rod to stop the car crabbing?

In the picture above you appear to be missing the inner and outer washer, the make up in total should be:

Thick washer

Rubber bush

Thin washer

Body panhard rod mount

Thin washer

Rubber bush

Thick washer

Nut

With the distance pice going through the parts above in red.

I'm interested in the comment above about fixed length panhard rods, what cars were these on as my 1959 MK2 has an adjustable one? I can't see how they would have adjusted the rear suspension with a fixed rod to stop the car crabbing?

#13

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

Homer,

Mk1. 2.4

PRODUCTION CHANGES (1955– 57)

The new Jaguar suffered from surprisingly few teething troubles in view of the amount of new engineering it incorporated. The service bulletins that Jaguar issued to their dealers reveal that many minor changes were made to the car’s specification, but that few of these were to counter serious faults. Perhaps the biggest problem was that the Panhard rod mounting on the bodyshell was weak, and a number of breakages were reported. So in May 1956, Jaguar advised dealers to weld a reinforcing plate to customers’ cars, and at the same time introduced an adjustable rod in production, which allowed the correct tension to be maintained. This continued to occur on a few cars & the plant advised further strengthening of the mounting points. Other problems concerned the rear springs, which could create irritating knocking noises. The first modifications were made in autumn 1956, when a new front mounting plate was added in production and the spring leaves gained rubber ends. Unfortunately, this was not the whole answer, and further reports of problems came in. So early in 1957, Jaguar advised their dealers to check for distortion of the spring mounting clamps. Even that did not cure the problem completely, and the service bulletins would continue to offer suggestions for dealing with the problem right through into 1958. The problem was never really completely solved & carried on into the Mk2's.

Many Scribes. Credit Taylor in this case for the wording.

Homer I have seen a few problems on Mk2's in racing. Mostly when they go back to a solid Panhard rod to reduce compliance that improved handling on cars with the wider rear axle.

As Aston Martin says (and any sensible manufacturer). Stiff Chassis, Minimum of compliance = better handling. Why American cars with oodles of compliance could be so dangerous in anything but a straight line.

Bill & I are discussing both Mk1 & Mk2 cars.

Mk1. 2.4

PRODUCTION CHANGES (1955– 57)

The new Jaguar suffered from surprisingly few teething troubles in view of the amount of new engineering it incorporated. The service bulletins that Jaguar issued to their dealers reveal that many minor changes were made to the car’s specification, but that few of these were to counter serious faults. Perhaps the biggest problem was that the Panhard rod mounting on the bodyshell was weak, and a number of breakages were reported. So in May 1956, Jaguar advised dealers to weld a reinforcing plate to customers’ cars, and at the same time introduced an adjustable rod in production, which allowed the correct tension to be maintained. This continued to occur on a few cars & the plant advised further strengthening of the mounting points. Other problems concerned the rear springs, which could create irritating knocking noises. The first modifications were made in autumn 1956, when a new front mounting plate was added in production and the spring leaves gained rubber ends. Unfortunately, this was not the whole answer, and further reports of problems came in. So early in 1957, Jaguar advised their dealers to check for distortion of the spring mounting clamps. Even that did not cure the problem completely, and the service bulletins would continue to offer suggestions for dealing with the problem right through into 1958. The problem was never really completely solved & carried on into the Mk2's.

Many Scribes. Credit Taylor in this case for the wording.

Homer I have seen a few problems on Mk2's in racing. Mostly when they go back to a solid Panhard rod to reduce compliance that improved handling on cars with the wider rear axle.

As Aston Martin says (and any sensible manufacturer). Stiff Chassis, Minimum of compliance = better handling. Why American cars with oodles of compliance could be so dangerous in anything but a straight line.

Bill & I are discussing both Mk1 & Mk2 cars.

Last edited by Glyn M Ruck; 09-07-2022 at 05:16 AM.

#14

Join Date: Nov 2012

Location: Joyner, Queensland, Australia

Posts: 960

Received 1,068 Likes

on

626 Posts

I am wondering why the nut came off the panhard rod in DaveinG's car in the first place.

It clearly requires a nut but unlike the shock absorber does not specify a "locking nut'

I believe it should have been a "NYLOC" nut in the first place. At least that is what I use.

Perhaps the previous owner used a previously used nyloc nut or just a plain nut. Both are bound to let go/fail in suspension related fastenings with vibration and shocks.

In aviation a nyloc nut is a single use device which is normally discarded after a single use.

Nyloc nuts are readily available in SAE threads from aviation sources such as "Spruce" at better prices than Jaguar retailer sources

It clearly requires a nut but unlike the shock absorber does not specify a "locking nut'

I believe it should have been a "NYLOC" nut in the first place. At least that is what I use.

Perhaps the previous owner used a previously used nyloc nut or just a plain nut. Both are bound to let go/fail in suspension related fastenings with vibration and shocks.

In aviation a nyloc nut is a single use device which is normally discarded after a single use.

Nyloc nuts are readily available in SAE threads from aviation sources such as "Spruce" at better prices than Jaguar retailer sources

The following users liked this post:

Glyn M Ruck (09-07-2022)

#15

The following users liked this post:

Glyn M Ruck (09-07-2022)

#16

I have to admit that I'm a bit confused by the non-adjustable Panhard rod and it's possible advantages. If the rod doesn't have a combination of male and female threaded sections, I don't see how it can be fitted without forcing the whole axle sideways an inch, difficult on a production line apart from regular maintenance.

Also, I don't understand how the threaded connection of the two parts increases compliance. It must be negligible compared with that of the rubber buffers? I can imagine some racers might replace the rubber buffers with steel washers in the search for greater stiffness. I'm also pretty sure that makes it difficult or impossible for the Panhard rod to go up and down with the axle, resulting in a bent rod or fracture of the mount. There are definitely limits on motion there - even with the rubber my Panhard rod was bent.

I'm not arguing with Glyn's references, just baffled by what they are saying. Certainly, that part of the car received a lot of modifications. I'm wondering if some of the scribes have misinterpreted the details?

Also, I don't understand how the threaded connection of the two parts increases compliance. It must be negligible compared with that of the rubber buffers? I can imagine some racers might replace the rubber buffers with steel washers in the search for greater stiffness. I'm also pretty sure that makes it difficult or impossible for the Panhard rod to go up and down with the axle, resulting in a bent rod or fracture of the mount. There are definitely limits on motion there - even with the rubber my Panhard rod was bent.

I'm not arguing with Glyn's references, just baffled by what they are saying. Certainly, that part of the car received a lot of modifications. I'm wondering if some of the scribes have misinterpreted the details?

Last edited by Peter3442; 09-07-2022 at 05:28 AM.

#17

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

I don't know Peter. I learn by reading as most of us do. It's not our original thought. What I do know is that the solid non adjustable Panhard rod existed & I've seen the mounting ripped out of the body. I only know the S Type down to it's last nut, bolt & washer because that is what I did a ground up restoration on. The rest is learning from reading. What ads credence to the comment is the number of scribes that mention it and the fact that I've seen it with my own eyes. Plus the fact that the plant produced Dealer Bulletins on the issue numerous times to strengthen mounting points. I think there were always rubbers to accommodate movement up & down within reason. Length could not be changed (by much) for centering the axle & tensioning originally.

I shall undertake to search for such bulletins in the forlorn hope of finding them. CF should have them but are frequently not prepared to share unless there is something in it for them ~ e.g. win an argument.

I shall undertake to search for such bulletins in the forlorn hope of finding them. CF should have them but are frequently not prepared to share unless there is something in it for them ~ e.g. win an argument.

Last edited by Glyn M Ruck; 09-07-2022 at 07:17 AM.

#18

Join Date: Nov 2012

Location: Joyner, Queensland, Australia

Posts: 960

Received 1,068 Likes

on

626 Posts

In 6 MK1s and 6 Mk2s I have never encountered a non-adjustable panhard rod.

That doesn't mean that they don't exist but are uncommon or early models or special order.

They may have been used on early Mk1s, but I have no experience of that model prior to an August 1957 build.

Perhaps we are "chasing rainbows"?

That doesn't mean that they don't exist but are uncommon or early models or special order.

They may have been used on early Mk1s, but I have no experience of that model prior to an August 1957 build.

Perhaps we are "chasing rainbows"?

#19

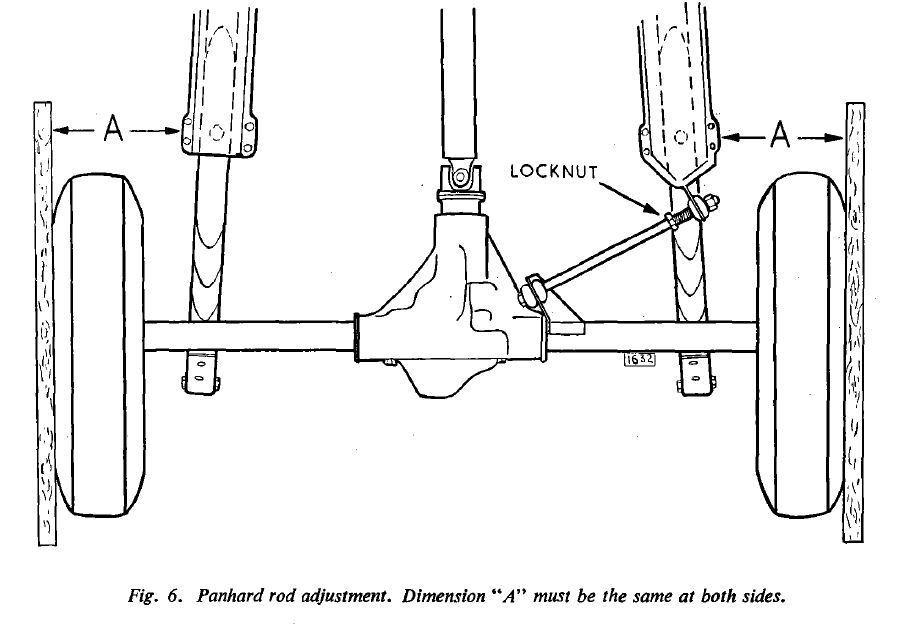

Job done! I received and fitted the Panhard rod end fittings. It was a fiddle to get the distance piece into the holes in the bracket and inner washer beyond. I believe that the distance piece also protects the threads on the adjustable part of the rod and provides a running surface at the bracket hole. I had to lengthen the rod to mount the outside fittings (inner washer, rubber bush, outer washer and nyloc locking nut) then screw it back to its original length before tightening up the locknut.

The ‘A’s measurement (car down from the lift and same tyre pressure at both rear wheels) meant I had to lengthen the rod to equalize the measurements.

Thanks again for your help and the interesting facts!

Dave

The ‘A’s measurement (car down from the lift and same tyre pressure at both rear wheels) meant I had to lengthen the rod to equalize the measurements.

Thanks again for your help and the interesting facts!

Dave

The following users liked this post:

Glyn M Ruck (09-07-2022)

#20

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,511

Received 1,476 Likes

on

1,147 Posts

In 6 MK1s and 6 Mk2s I have never encountered a non-adjustable panhard rod.

That doesn't mean that they don't exist but are uncommon or early models or special order.

They may have been used on early Mk1s, but I have no experience of that model prior to an August 1957 build.

Perhaps we are "chasing rainbows"?

That doesn't mean that they don't exist but are uncommon or early models or special order.

They may have been used on early Mk1s, but I have no experience of that model prior to an August 1957 build.

Perhaps we are "chasing rainbows"?

I would like what is supposed to be at the end of the rainbow.

Thread

Thread Starter

Forum

Replies

Last Post

Kasper Lundberg Lykkegaard

MKI / MKII S type 240 340 & Daimler

2

03-25-2021 07:13 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)