Rebuilding Burman(?) PA steering box

#61

Glad to be of help. When I rebuilt the lower column (that I eventually sourced) I managed to stretch the new rubber boot/gaiter over the UJ end (it was apart anyway as I was going to fit a new UJ). It took a while with plenty of grease but eventually got it on. Probaby a bit late now but did you not think about mounting the Vauxhall pump on the left hand inner wing as per the Wilkinson rack conversion. I managed to use the original Vauxhall mounting bracket (with a few bits cut off and a few bits welded on) It's quite a substantial, strong bracket and holds the pump firmly in place (I'll post a picture later with it in situ). Wilkinson supplied a bracket with their

rack conversion but it looks quite spindly to me. Is your car an S Type - MK2's don't have a servo under the left-hand wheelarch (not in the UK anyway) ? Kind regards Keith

rack conversion but it looks quite spindly to me. Is your car an S Type - MK2's don't have a servo under the left-hand wheelarch (not in the UK anyway) ? Kind regards Keith

#63

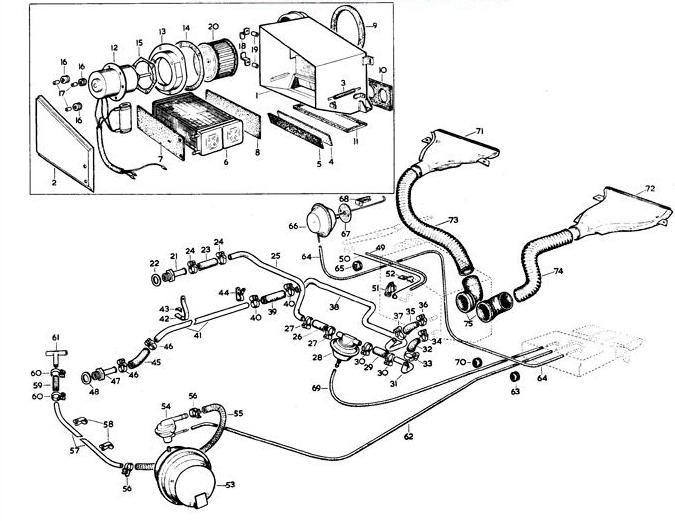

Ah, I see - the air reservoir under the wheelarch is for the heater on the S Type. I'll post pictures of the Vauxhall bracket in situ in a minute (I've got to do it using my mobile - for some reason I'm unable to post pictures on my PC ??) Ignore the dirty Vauxhall pump & short stumpy wires sticking out of it - that's not the one I'm going to use

#65

#66

Not quite Jose. On the S type it supplies vacuum for the scuttle switch and the water vacuum switch for the heater. The brake booster tank is under the right hand wing and I think that is the same as the Mk2. The Mk2 does not have the S Type bell shaped vacuum tank under the left wing as both their scuttle and heater switches are operated by cable.

#67

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,476

Received 1,465 Likes

on

1,137 Posts

#69

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,476

Received 1,465 Likes

on

1,137 Posts

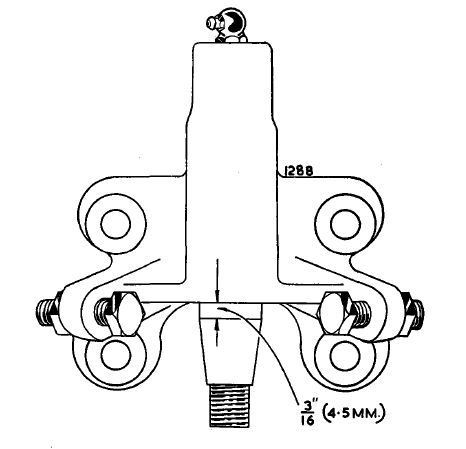

Good news ~ You might have to arrange some lock stops for the beefed up arms. Most Mk2's had a different arrangement. Protrusions from the beefed up arms hit these newer lockstops.

Old style Mk2 lock stops on idler only. PAS can break the lugs off.

Last edited by Glyn M Ruck; 07-14-2020 at 06:42 PM.

#70

With regards the hose routing - I'm planning to go forward along the left-hand inner wing, down to the crossmember and then along the front of same to the box. I did look at going around the back of the engine but theres already a plethora of wires & pipes there, plus it would've meant some odd angles on the metal pipes at each end of the hose. As an aside, I was going to collect the newly made hose yesterday BUT they made it up

wrongly - for some reason they put S bends in the metal pipes instead of simple right-angles (Luckily they phoned me to check before I made the 30 mile trip - he must've realised his error). Just waiting for the phone call

now to say when its ready, but I'll ask for a photo before going. I'll likely route the Low Pressure hose alongside the HP one.

Thanks for the advice regarding the stops Glynn. Looks like the part number for those 'special' bolts is C16036 (one for idler and one for box) - surprise, surprise NLA. Will have to improvise

wrongly - for some reason they put S bends in the metal pipes instead of simple right-angles (Luckily they phoned me to check before I made the 30 mile trip - he must've realised his error). Just waiting for the phone call

now to say when its ready, but I'll ask for a photo before going. I'll likely route the Low Pressure hose alongside the HP one.

Thanks for the advice regarding the stops Glynn. Looks like the part number for those 'special' bolts is C16036 (one for idler and one for box) - surprise, surprise NLA. Will have to improvise

#71

#72

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,476

Received 1,465 Likes

on

1,137 Posts

Last edited by Glyn M Ruck; 07-15-2020 at 09:12 PM.

#73

The following users liked this post:

Glyn M Ruck (07-26-2020)

#74

Hi everyone,

Just a thought - as I've already posted I'm in the process of fitting a rebuilt Burman power steering box, supplied with pressure from a Vauxhall/GM electric pump, located on the left-hand inner wing. One thing which has

concerned me is the potential loss of feel through the steering wheel at any speed above crawl (at present, with the manual steering box I like the feedback. It's just the massive effort required when parking etc that has

prompted this conversion). I'm now wondering whether I could fit an on/off switch into the electric pump supply so that I can have power steering when required ??? Would the power steering box be as usable without the

high pressure fluid going through it, or could it potentially cause damage ??? Any suggestions or thoughts anyone ???

Just a thought - as I've already posted I'm in the process of fitting a rebuilt Burman power steering box, supplied with pressure from a Vauxhall/GM electric pump, located on the left-hand inner wing. One thing which has

concerned me is the potential loss of feel through the steering wheel at any speed above crawl (at present, with the manual steering box I like the feedback. It's just the massive effort required when parking etc that has

prompted this conversion). I'm now wondering whether I could fit an on/off switch into the electric pump supply so that I can have power steering when required ??? Would the power steering box be as usable without the

high pressure fluid going through it, or could it potentially cause damage ??? Any suggestions or thoughts anyone ???

#75

Interestingly the gentleman who I got the kit from addressed exactly this point. He said it was reasonably easy to lower the amount of "help" the pump supplied and once this was done you got good feel. Once mine is in I will see what it feels like and if needs be I will contact him and ask what is involved. Not sure whether it is an electrical fix to the pump or some physical method of lowering the pressure but apparently it can be done.

#76

That's very interesting - if correct then perhaps a rheostat could be incorporated to adjust the voltage supplied ?? We must keep in touch to find the ideal solution. Good luck !! Have you managed to wire your pump

up yet ? I eventually got my HP hose made up (after the ****-up that they made) and I've trial-fitted it in the engine bay - looks OK so I've now ordered the LP hose plus a brass adaptor/reducer as the Vauxhall pump

nozzle is 10mm and the Jaguar steering box nozzle is 14.5mm. I shan't be doing the upgrade just yet as I have family issues and business things to keep me occuppied - lol !!

up yet ? I eventually got my HP hose made up (after the ****-up that they made) and I've trial-fitted it in the engine bay - looks OK so I've now ordered the LP hose plus a brass adaptor/reducer as the Vauxhall pump

nozzle is 10mm and the Jaguar steering box nozzle is 14.5mm. I shan't be doing the upgrade just yet as I have family issues and business things to keep me occuppied - lol !!

#77

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,476

Received 1,465 Likes

on

1,137 Posts

I would find a way to vary the pressure to resolve. On my car at least, the steering was easy to wind around pre fluid. We were pushing the car around to access different things. Once the system is prirned & bled with fluid the steering is extremely heavy without any pump pressure. I don't think an on/off switch is the answer. I think being able to vary the pressure from low to 1000psi is the answer. I don't think you will have to fiddle with it all the time. I think you will find a compromise pressure setting that works for you to get away from Jaguar's stock overboosted feeling at speed.

I'm told it can also be done by adjusting/modifying the pressure/flow control valve on the standard Hobourn Eaton pump but have never tried.

Of course if you are electronically inclined you could put a speed pickup on the propshaft & build a control circuit that varied pressure with speed using an electric pump.

I'm told it can also be done by adjusting/modifying the pressure/flow control valve on the standard Hobourn Eaton pump but have never tried.

Of course if you are electronically inclined you could put a speed pickup on the propshaft & build a control circuit that varied pressure with speed using an electric pump.

Last edited by Glyn M Ruck; 07-26-2020 at 08:59 AM.

#78

Thanks Glyn,

I see what you're saying - I suppose the fluid present would cause some resistance (not a problem at higher road speeds of course). As this is 'unknown territory' I suppose it's a case of 'Suck It and See' . Putting a

switch onto the pump supply should be simple - pressure variation would be more complex (I believe Vauxhall incorporated a pressure varying system via the ECU but we don't have that option). Regards Keith

I see what you're saying - I suppose the fluid present would cause some resistance (not a problem at higher road speeds of course). As this is 'unknown territory' I suppose it's a case of 'Suck It and See' . Putting a

switch onto the pump supply should be simple - pressure variation would be more complex (I believe Vauxhall incorporated a pressure varying system via the ECU but we don't have that option). Regards Keith

#79

Join Date: Jul 2012

Location: Llandudno, Cape Town, South Africa

Posts: 5,476

Received 1,465 Likes

on

1,137 Posts

Even at higher speeds you would be fighting the hydraulics with no pump pressure.

Let's find out how wouldbeowner's mate varied the pump pressure. Probably quite simple. Might be as simple as a resistor of the right value in circuit with the pump.

Your rheostat idea will control a DC motor. There are just more efficient methods with very simple circuits that you can Google. (DC motor controller circuit)

Let's find out how wouldbeowner's mate varied the pump pressure. Probably quite simple. Might be as simple as a resistor of the right value in circuit with the pump.

Your rheostat idea will control a DC motor. There are just more efficient methods with very simple circuits that you can Google. (DC motor controller circuit)

Last edited by Glyn M Ruck; 07-26-2020 at 05:06 PM.

#80

The following users liked this post:

Glyn M Ruck (07-27-2020)