05 STR Catalyst Efficiency issues

#21

#22

I feel like you're trying to tell me something about my assumptions or the direction I'm headed. JagV8 has lit me up plenty about doing anything other than fixing the problems pointed to by the codes. This post thread, unfortunately, is a misnomer. The lean condition is a bigger problem right now than catalyst efficiency.

Ken

Ken

At any rate carry on and post up some pics because I'm sure I'll be following down this road this winter on my XKR.

The following users liked this post:

KenAdamson (06-27-2017)

#23

No Ken, quite the opposite. I think your fixing the seals will fix the cat efficiency problems. Your MAF and MAP are saying the engine is running unhappy and the o2's are saying the engine is lean causing the trims to max out which will hurt your cats if left unchecked. Downstream o2 aren't happy because they are reading too rich and it's coding on that vs. an engine efficiency problem because OBDii cares about emissions more than performance. If you squint your eyes and think about it, it could make sense.

At any rate carry on and post up some pics because I'm sure I'll be following down this road this winter on my XKR.

At any rate carry on and post up some pics because I'm sure I'll be following down this road this winter on my XKR.

It's interesting watching the LTFT relearn. As I sat at stoplights, idling, the trim levels - which had been firewalled at +19.5%, started creeping down slowly. As they came down, STFT crept up (from very negative to offset the big positive LTFT). I studied industrial control logic, feedback, hysteresis, damping and all that in college. Never really used it (except for a few "clever" robotics projects), but it's cool watching it all work together in the car...

Ken

#24

#25

However, to directly address your question, I've run across plenty of seized bolts on exhaust systems before. PB Blaster + torch is generally the magic to getting those unstuck. The last time I did exhaust work was on a Suburban. I didn't even bother taking a wrench to those nuts (exhaust manifold is mounted on studs). First, I soaked them with PB Blaster and let them sit overnight. Next day, sprayed more and took a torch after them. They came off easy

Ken

#27

Exhaust wasn't that bad. Put the car on decent stands, spray the connections and bolts. Then run it until the just starts to evaporate. Shut it off, spray it again and loosen while hot. I mangled one of the resonance straps on a cat when a bolt refused to come apart. Took a couple applications of heat and juice before everything came apart. That part is in by rebuild thread if you want pics.

#28

"I already have the stupid brake booster hose seal kit, so there's that."

the repair would be better modified as:

https://www.jaguarforums.com/forum/x...ng-fix-105997/

the repair would be better modified as:

https://www.jaguarforums.com/forum/x...ng-fix-105997/

#32

You will never get the factory fitting out and replaced while it's on the car.

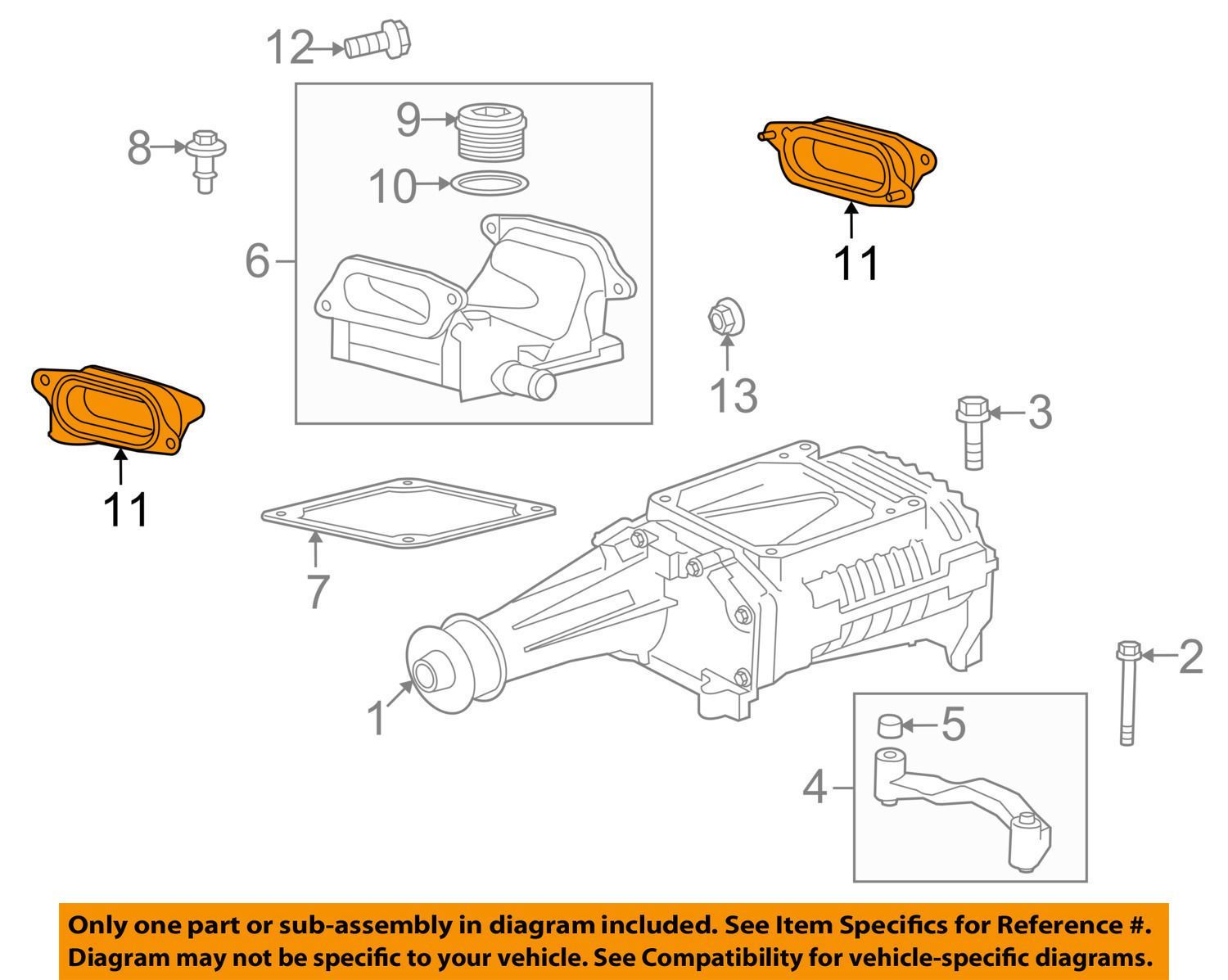

Yes the SC inlet elbow needs to be removed to do the repair. You need to knock the factory brass fitting out from the inside of the elbow.

Note the plumbing brass fitting will cut new threads when screwed in so no need to thread or enlarge the factory hole.

Sorry!

.

.

.

Yes the SC inlet elbow needs to be removed to do the repair. You need to knock the factory brass fitting out from the inside of the elbow.

Note the plumbing brass fitting will cut new threads when screwed in so no need to thread or enlarge the factory hole.

Sorry!

.

.

.

#33

Well, I replaced the SC outlet duct seals. Re-smoked afterward, and it looks like the last one is the brake booster hose to the TB. I dabbed a little JB weld on the hose-brass fitting junction after cleaning it with carb cleaner, then electronic parts cleaner. It's a hack, but it'll do until I can find a day to tear it all out and do it proper.

At least my fuel trims are within reason again Next thing on the agenda is actually a transmission drain and fill - a first for me with this car...

Next thing on the agenda is actually a transmission drain and fill - a first for me with this car...

At least my fuel trims are within reason again

Next thing on the agenda is actually a transmission drain and fill - a first for me with this car...

Next thing on the agenda is actually a transmission drain and fill - a first for me with this car...

#35