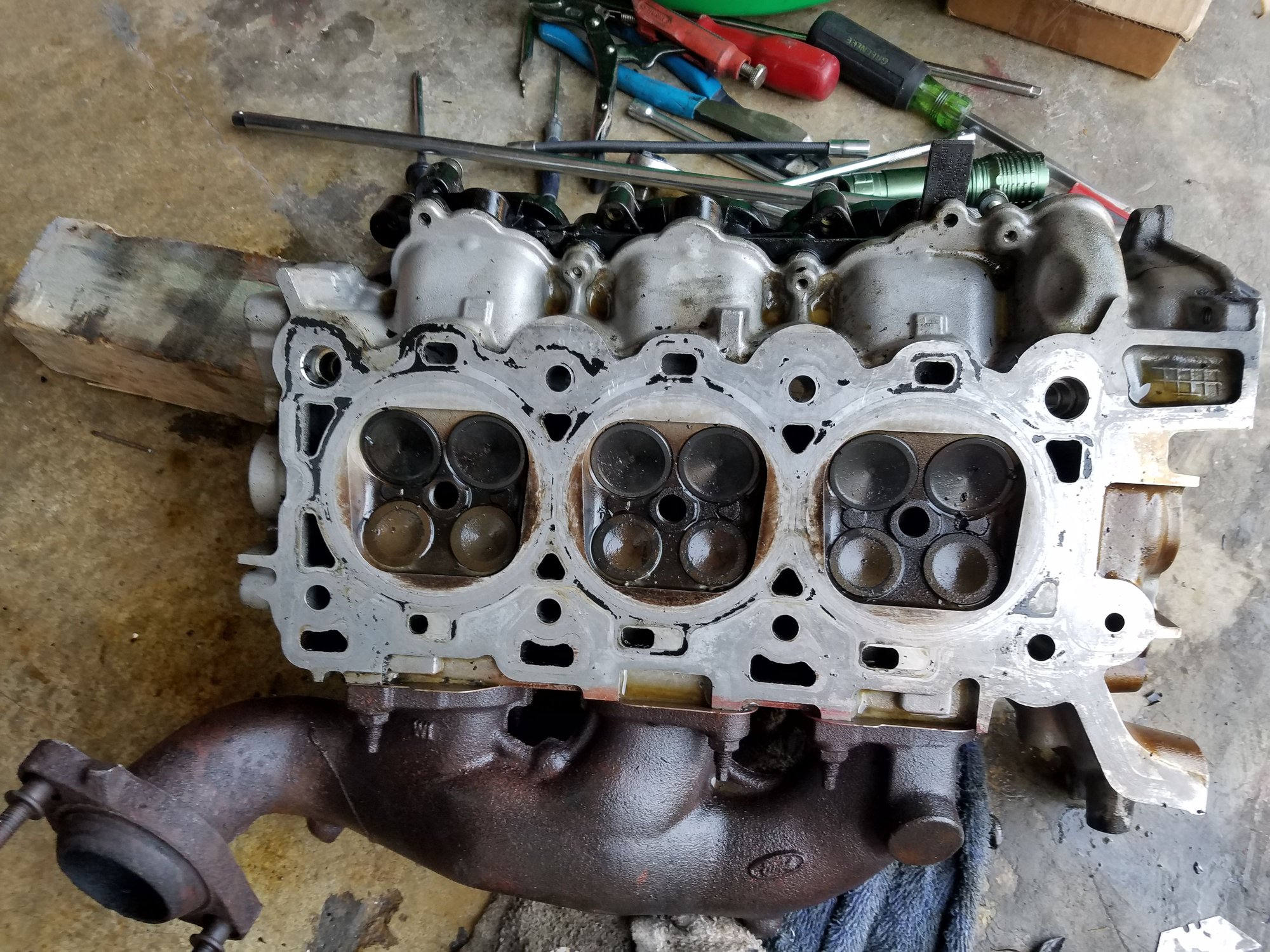

head gasket! maybe or cooling !

#61

Can you get hold of a bottle of blue-metal-marking-layout-ink ?

put a thin layer on a sheet of glass and move the clean cylinder heads on the glass sheet move the head around. turn around head and look to see if any Areas do not have ink on it. If so heads are warped.

to check the pistols pins are all right go to this thread it shows what to do on a youtube vid

https://www.jaguarforums.com/forum/s-type-s-type-r-supercharged-v8-x200-15/engine-knocking-sound-2001-jaguar-s-type-173459/#post1581168

put a thin layer on a sheet of glass and move the clean cylinder heads on the glass sheet move the head around. turn around head and look to see if any Areas do not have ink on it. If so heads are warped.

to check the pistols pins are all right go to this thread it shows what to do on a youtube vid

https://www.jaguarforums.com/forum/s-type-s-type-r-supercharged-v8-x200-15/engine-knocking-sound-2001-jaguar-s-type-173459/#post1581168

The following users liked this post:

jaimster (12-10-2016)

#62

yea Ducmon .. I can try to get those things from home depot or wallmart the ink.. I will take a picture of the other side of the heads forgot to do that ..

I just watched the video.. how ever I'm not sure if its a good idea to turn the crankshaft with out the timing chains on ! without the heads no cams on ! what do you think?

and I also have a straight edge and gauge that I was going to use to check on the heads warp condition ??

I just watched the video.. how ever I'm not sure if its a good idea to turn the crankshaft with out the timing chains on ! without the heads no cams on ! what do you think?

and I also have a straight edge and gauge that I was going to use to check on the heads warp condition ??

Last edited by jaimster; 12-10-2016 at 04:33 PM.

#63

#64

the chains look good .. I think ! I will clean everything tomorrow and post couple of photos .. I had a hard time releasing tension on both tensioner so I just ended up removing the bolts to get tension off .. I didn't know how to release the tension I DO NOW... I hope I can still use same tensioners

the head gaskets ! looks like some of silicon had was coming off as when I was loosing the cylinder bolts I found: the passenger side -- I found the back cylinder bolts were not TIGHT AT ALL... loose on driver side too..

not as bad when you compare how the other were they were pretty tight..

just remember I have a bottle of black printer ink is it possible to use that ink ??

the head gaskets ! looks like some of silicon had was coming off as when I was loosing the cylinder bolts I found: the passenger side -- I found the back cylinder bolts were not TIGHT AT ALL... loose on driver side too..

not as bad when you compare how the other were they were pretty tight..

just remember I have a bottle of black printer ink is it possible to use that ink ??

Last edited by jaimster; 12-11-2016 at 03:36 PM.

#65

I don't think that printer ink will work because it is not designed to work with metal.

but you can make your own

https://en.m.wikipedia.org/wiki/Engineer%27s_blue.

very strange that the bolts were loose was there any signs that somebody had been there before you because it sounds like someone had not torgued the heads up correctly.

but you can make your own

https://en.m.wikipedia.org/wiki/Engineer%27s_blue.

very strange that the bolts were loose was there any signs that somebody had been there before you because it sounds like someone had not torgued the heads up correctly.

The following users liked this post:

jaimster (12-11-2016)

#66

no signs ! that somebody had messed with it before .. no way to know for sure ..

wallmart sells the stuff I will just order it from them may take few days to get it thought .

anyways I'm still waiting for gasket kit from rock auto,, as far as testing the piston I watched the video . I'm hesitant on turning the crankshaft with out the chains!!

I did pushed on the pistons felt NO Movement at all !

here is an idea : how about if I mark the crankshaft keyway position , them turn the crankshaft one full turn checking pistons as I turning it clockwise NOT COUNTER . definetly would like to verify pistons are ok IF possible like on the video.

do you think I wont get into trouble doing that ?

also I did have loosen the oil pan to get cover off do you think I can get away using same oil pan gasket ? was thinking about putting a bead of gasket silicon around pan before tighten down the pan again..

wallmart sells the stuff I will just order it from them may take few days to get it thought .

anyways I'm still waiting for gasket kit from rock auto,, as far as testing the piston I watched the video . I'm hesitant on turning the crankshaft with out the chains!!

I did pushed on the pistons felt NO Movement at all !

here is an idea : how about if I mark the crankshaft keyway position , them turn the crankshaft one full turn checking pistons as I turning it clockwise NOT COUNTER . definetly would like to verify pistons are ok IF possible like on the video.

do you think I wont get into trouble doing that ?

also I did have loosen the oil pan to get cover off do you think I can get away using same oil pan gasket ? was thinking about putting a bead of gasket silicon around pan before tighten down the pan again..

Last edited by jaimster; 12-11-2016 at 07:12 PM.

#67

#68

#69

#71

#73

#74

Have you cleaned the barrels yet? If not do it and spray some oil in them to stop any rust.

Don't forget to get a new oil pan gasket as you had to loosen the oil pan. it's not worth the risk of using the old one after you have done all this hard work and invested all the time and money.

its looking good just take your time and keep checking the manual.

Don't forget to get a new oil pan gasket as you had to loosen the oil pan. it's not worth the risk of using the old one after you have done all this hard work and invested all the time and money.

its looking good just take your time and keep checking the manual.

Last edited by Ducmon; 12-13-2016 at 10:42 AM.

#75

oh yea ! I almost forgot I will get a oil pan gasket too.. do I have to lift the engine to replace it ? I will look at the FSM and I will spray some oil on barrels too

..I will have to get back on the project till next week ,, this week I'm doing a home project ceiling texture on family room and kitchen .. removed old pop corn on / off project few months now .. decided to get it done finally ..

gracias ..

..I will have to get back on the project till next week ,, this week I'm doing a home project ceiling texture on family room and kitchen .. removed old pop corn on / off project few months now .. decided to get it done finally ..

gracias ..