Spark plug questions

#1

#2

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,859

Received 10,916 Likes

on

7,172 Posts

The following users liked this post:

Don B (03-10-2017)

#3

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,859

Received 10,916 Likes

on

7,172 Posts

I ran my XJR with .035 because somebody put the notion in my head that it might be easier on the notoriously troublesome coils. But there was certainly no palpable difference in driving experience vs. .038

Cheers

DD

Cheers

DD

#4

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,556

Received 13,103 Likes

on

6,529 Posts

Those are great questions, Scotlad!

I apologize in advance for the length of this post, but once I got started I couldn't stop (so what else is new?).

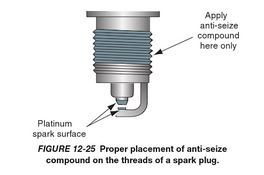

Professional recommendations on the use of anti-seize on spark plug threads have changed in recent years. Here's a diagram from a traditional automotive textbook:

In my maybe not-so-humble opinion, that is a lot of anti-seize, given that the ground path for the spark plug is the threaded junction between the plug shell and cylinder head bore. If anti-seize compound works its way onto all of the threads, undesirable electrical resistance is added to the ground path. A Champion Aerospace manual specified that anti-seize compound should be applied only to "threads 2 and 3" of the plug, which I assumed really meant "2 or 3 threads."

Another issue is that anti-seize compounds are typically based on grease, which reduces friction and can lead to over-torquing the plugs. Here are a couple of technical bulletins published by NGK:

Anti-Seize Compounds on Spark Plug Threads Ver. 1

Anti-Seize Compounds on Spark Plug Threads Ver. 2

The Autolite spark plug technical training manual includes this statement in its installation instructions: "Do not use any grease or lubricant on the spark plug threads since this may result in over-torquing the spark plugs, and could lead to engine damage."

Autolite Spark Plug Technical Training Manual

However, because certain Ford V8 engines with aluminum heads have had problems with difficult-to-remove spark plugs, Ford recommended the following in TSB 08-7-6: "NEW PLUGS SHOULD BE INSTALLED USING A FILM COATING OF MOTORCRAFT HIGH TEMPERATURE NICKEL ANTI-SEIZE LUBRICANT ON THE GROUND ELECTRODE SHIELD. DO NOT COAT THE ELECTRODE STRAP."

Likewise, when Jaguar introduced the X350, the Workshop Manual specified the use of nickel anti-seize on the NGK plugs. However, NGK now applies a special "trivalent" plating to all of its plugs to prevent seizing in aluminum heads, and cautions that anti-seize compound should not be used. But notice the photos of unplated plugs at the end of the NGK bulletin with aluminum from the cylinder head bonded to the threads, which seems to be strong evidence that anti-seize should be used on unplated plugs.

Champion has traditionally offered a graphite-based lubricant for aeronautical engines but that product does not appear to be currently available. In their automotive spark plug listings, Champion does not mention special plating, yet in their online automotive spark plug installation instructions the use of anti-seize is conspicuous by its absence:

Champion Spark Plug Installation Guide

The NGK bulletins state that "plugs that have a shiny silver appearance on the metal body usually indicate that the spark plug is manufactured with a special metal shell plating," and therefore no anti-seize should be used with these plugs.

Regarding the plug gap, the original specification for the RC9YCC plug was 0.35 in. / 0.9 mm. In 1995 Jaguar recommended a change for N/A engines to the hotter RC12YCC, also with a gap of 0.035 inch:

Jaguar TSB 12-54

And again in 1998 when the recommendation for the hotter RC12YCC was extended to the S/C engines, the gap was specified as 0.35 inch:

Jaguar TSB 05.1-07

But in 2001, for AJ16 engines experiencing rough idle and drivablility issues, Jaguar recommended the plug gap be increased to 0.38 in. / 0.96 mm. The TSB below is for the XJS, but I think the same recommendation was made for the XJ sedans with the AJ16, I just didn't find the TSB in a quick search:

Jaguar TSB 18-56

Cheers,

Don

Last edited by Don B; 03-12-2017 at 11:52 AM.

The following 8 users liked this post by Don B:

aholbro1 (03-11-2017),

al_roethlisberger (03-11-2017),

b1mcp (03-11-2017),

Doug (03-11-2017),

littlelic69 (03-11-2017),

and 3 others liked this post.

#5

Wow, that's quite an informative post... and you know it got me thinkin'

.....that might explain why my XJR started missing a bit more after I refreshed the plugs recently. Perhaps I put too much, or the wrong kind, of anti-seize

Now that I think about it and consider the post above, since I change my plugs every year maybe anti-seize is overkill. Has anyone had any issues removing the Champion plugs when not using anti-seize? A lot of other reading on the subject suggest the silver plated versus black steel bodied plugs don't need anti-seize.

Apparently the CRC copper and nickel anti-seize products are conductive though:

http://www.crcindustries.com/product...z-SL35911.html

http://www.crcindustries.com/product...z-SL35903.html

Not sure if the cheap packet of anti-seize I used is conductive though.

.

.....that might explain why my XJR started missing a bit more after I refreshed the plugs recently. Perhaps I put too much, or the wrong kind, of anti-seize

Now that I think about it and consider the post above, since I change my plugs every year maybe anti-seize is overkill. Has anyone had any issues removing the Champion plugs when not using anti-seize? A lot of other reading on the subject suggest the silver plated versus black steel bodied plugs don't need anti-seize.

Apparently the CRC copper and nickel anti-seize products are conductive though:

http://www.crcindustries.com/product...z-SL35911.html

http://www.crcindustries.com/product...z-SL35903.html

Not sure if the cheap packet of anti-seize I used is conductive though.

.

Last edited by al_roethlisberger; 03-11-2017 at 09:00 PM.

The following users liked this post:

Don B (03-11-2017)

#6

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,859

Received 10,916 Likes

on

7,172 Posts

.....that might explain why my XJR started missing a bit more after I refreshed the plugs recently. Perhaps I put too much, or the wrong kind, of anti-seize

Now that I think about it and consider the post above, since I change my plugs every year maybe anti-seize is overkill.

If you use too much anti-seize it migrates upward when the plugs are installed. What I've seen happen in some cases is that, over a period of years and several spark plug changes, a build-up anti-seize develops on the surface where the spark plug seats......preventing a reliable ground.

Pull a couple plugs and check for a layer of anti-seize!

Cheers

DD

The following 2 users liked this post by Doug:

al_roethlisberger (03-11-2017),

Don B (03-11-2017)

#7

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,859

Received 10,916 Likes

on

7,172 Posts

My understanding from a couple of spark plug websites is plugs with untreated/in-plated threads....black metal....need anti-seize. Plugs with plated threads....shiny metal; nickel or whatever....don't need anti-seize.

Anyone else read the same thing?

Cheers

DD

The following users liked this post:

al_roethlisberger (03-11-2017)

Trending Topics

#8

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,859

Received 10,916 Likes

on

7,172 Posts

Might depend on the plugs....and how long they've been left untouched

My understanding from a couple of spark plug websites is plugs with untreated/in-plated threads....black metal....need anti-seize. Plugs with plated threads....shiny metal; nickel or whatever....don't need anti-seize.

Anyone else read the same thing?

Cheers

DD

My understanding from a couple of spark plug websites is plugs with untreated/in-plated threads....black metal....need anti-seize. Plugs with plated threads....shiny metal; nickel or whatever....don't need anti-seize.

Anyone else read the same thing?

Cheers

DD

Silly me; I forgot this was already covered in the links provided above. Sorry!

Cheers

DD

The following users liked this post:

Don B (03-11-2017)