Suspension tools to borrow or rent?

#2

If a member or patron you may loan almost any factory tool from www.coventryfoundation.org or www.jcna.com. Note these are factory tools--not cheap knock offs.

#3

We quit using the Jaguar ball joint separator press tool when somebody bent the $h!t out of it and ruined it.

Just went back to the BFH or air hammer procedure.

The lower ball joint is part of the control arm unless you are going 'aftermarket' and then you will need a shop press.

No other special tools I can think of that don't have a 'workaround'.

(mark the eccentric bolts for alignment)

Just went back to the BFH or air hammer procedure.

The lower ball joint is part of the control arm unless you are going 'aftermarket' and then you will need a shop press.

No other special tools I can think of that don't have a 'workaround'.

(mark the eccentric bolts for alignment)

#4

#5

I've gone through a few of those MTC LCA's on both sides of my XJR. I'd avoid them if possible, but if it's absolutely necessary due to time/lack of tooling/cost etc, they will get you by. Don't pay more than $100 for them though. At $200 hunt around for some NOS Jaguar OE arms.

The ball joints on the MTC arms don't last as long as the OEM. They either develop play or a creak fairly quickly (think 5k-10k mi). The bore of the LBJ is also painted, oversized from OEM spec, and not consistent in dimensions on the one I tried to press apart when I was trying to replace the LBJ with one of the URO LBJ's.The bore was tapered!!! Witness marks on the bore showed that only about the upper half of the bore even had a fit with the ball joint body. The URO LBJ just dropped in with a loose fit, so if you buy an MTC arm, expect to have to buy another one once the LBJ wears out, rather than being able to service it.

Upsides are, they can often be found for cheap (I've paid $60-70 once or twice, other times usually in the $100 range) and don't require the tooling and risk of trying to press an LBJ out of an OE arm. My first arm I tried to service, I couldn't free the LBJ with my press and had to get an MTC arm instead to get me by.

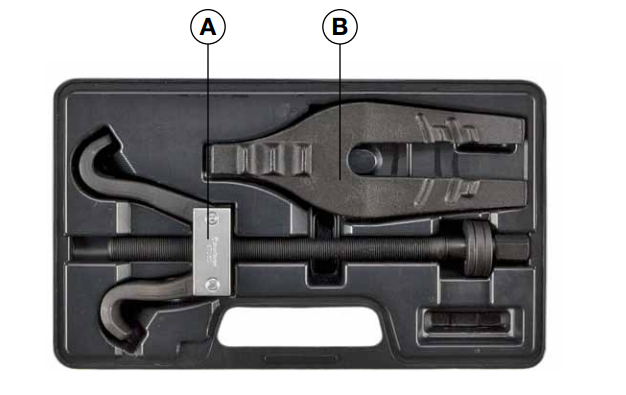

As for tooling, I have some spring compressors another forum member gave me that were made of some long allthread, with a pin through the top, and a nut with some pipe standoff and washers. And a 1 1/8 ratcheting combo wrench for that as well, absolute lifesaver when doing 30-50 turns under spring load. For ball joint separators, I have a standard 3-piece one bought from Harbor Freight (the kind with a fork and arm, and bolt that compresses the LBJ bolt), where I've ground the fork inside apart slightly larger to clear the LBJ boot. Usually it's enough if it's run down with an electric ratchet, sometimes it takes some tension from the separator plus a couple hammer hits to free the LBJ bolt. Hasn't bent yet, amazingly.

The ball joints on the MTC arms don't last as long as the OEM. They either develop play or a creak fairly quickly (think 5k-10k mi). The bore of the LBJ is also painted, oversized from OEM spec, and not consistent in dimensions on the one I tried to press apart when I was trying to replace the LBJ with one of the URO LBJ's.The bore was tapered!!! Witness marks on the bore showed that only about the upper half of the bore even had a fit with the ball joint body. The URO LBJ just dropped in with a loose fit, so if you buy an MTC arm, expect to have to buy another one once the LBJ wears out, rather than being able to service it.

Upsides are, they can often be found for cheap (I've paid $60-70 once or twice, other times usually in the $100 range) and don't require the tooling and risk of trying to press an LBJ out of an OE arm. My first arm I tried to service, I couldn't free the LBJ with my press and had to get an MTC arm instead to get me by.

As for tooling, I have some spring compressors another forum member gave me that were made of some long allthread, with a pin through the top, and a nut with some pipe standoff and washers. And a 1 1/8 ratcheting combo wrench for that as well, absolute lifesaver when doing 30-50 turns under spring load. For ball joint separators, I have a standard 3-piece one bought from Harbor Freight (the kind with a fork and arm, and bolt that compresses the LBJ bolt), where I've ground the fork inside apart slightly larger to clear the LBJ boot. Usually it's enough if it's run down with an electric ratchet, sometimes it takes some tension from the separator plus a couple hammer hits to free the LBJ bolt. Hasn't bent yet, amazingly.

Last edited by nilanium; 01-02-2022 at 05:20 PM.

#6

#7

Trending Topics

#8

As for tooling, I have some spring compressors another forum member gave me that were made of some long allthread, with a pin through the top, and a nut with some pipe standoff and washers. And a 1 1/8 ratcheting combo wrench for that as well, absolute lifesaver when doing 30-50 turns under spring load. For ball joint separators, I have a standard 3-piece one bought from Harbor Freight (the kind with a fork and arm, and bolt that compresses the LBJ bolt), where I've ground the fork inside apart slightly larger to clear the LBJ boot. Usually it's enough if it's run down with an electric ratchet, sometimes it takes some tension from the separator plus a couple hammer hits to free the LBJ bolt. Hasn't bent yet, amazingly.

#9

Is the last post on this thread what you are talking about: https://www.jaguarforums.com/forum/x...estions-33958/

Here's what I've used:

#10

The Factory tool comes with two tapered pins to align the pan. The major benefit of the factory tool over all thread and safety is speed. With central winged turn buckle, and special fittings that allow for the reality that compression is not in a straight line, it is a well designed tool that works fast and safe.

The following users liked this post:

nilanium (01-04-2022)

#11

Thread

Thread Starter

Forum

Replies

Last Post

Mundrwood

MKI / MKII S type 240 340 & Daimler

1

01-04-2016 06:17 AM

SuperTrav

XJ XJ6 / XJ8 / XJR ( X350 & X358 )

30

11-18-2012 11:10 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)