6.7L V12 build

#101

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

nice work; it seems a while back (maybe last year), you showed the porting tools you use in Russia, somewhat different than what we use, USA/UK.

odd how basic common sense engineering changes form country to country, and still gets the job done!

not counting CNC work, that is another world, along with air flow bench!

odd how basic common sense engineering changes form country to country, and still gets the job done!

not counting CNC work, that is another world, along with air flow bench!

The following users liked this post:

xjsv12 (12-15-2016)

#102

I will be doing some work in the ports and bowls. I measured the intake runners and where they pinch just before the bowl there is about 0.001" difference in the diameter.

Also if I were you I would lay back the ridge at 45° around the intake valve to de-shroud it, remove the ridge between the intake and exhaust and remove the sharp edges. This will greatly help low lift flow and only take about 0.2 from CR.

Also if I were you I would lay back the ridge at 45° around the intake valve to de-shroud it, remove the ridge between the intake and exhaust and remove the sharp edges. This will greatly help low lift flow and only take about 0.2 from CR.

#103

A clear perspex plate with 2 holes and I used 50-50 ISO Alcohol / Water and green food colour. You'll notice the numbers I wrote on the head these are the preliminary cc's I did this with a syringe. I have just ordered a 50ml burette so I can do the job with better accuracy/repeatability.

#104

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

I will be doing some work in the ports and bowls. I measured the intake runners and where they pinch just before the bowl there is about 0.001" difference in the diameter.

Also if I were you I would lay back the ridge at 45° around the intake valve to de-shroud it, remove the ridge between the intake and exhaust and remove the sharp edges. This will greatly help low lift flow and only take about 0.2 from CR.

Also if I were you I would lay back the ridge at 45° around the intake valve to de-shroud it, remove the ridge between the intake and exhaust and remove the sharp edges. This will greatly help low lift flow and only take about 0.2 from CR.

warrjon good stuff ,i think you meant .100 thou diameter, not .001 thou!

that tight shape is to increase velocity when flow enters the bowl thereby increasing swirl as flow enters chamber!

seems Jag HE has to much swirl already, what say you?

The following users liked this post:

xjsv12 (12-15-2016)

#106

I meant there is 0.010" difference in diameter between the smallest and largest port diameter just before thew bowl. I need to adjust these so they are all the same.

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

EDIT" I meant 0.010" not 0.001" difference between port diameters

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

EDIT" I meant 0.010" not 0.001" difference between port diameters

Last edited by warrjon; 12-15-2016 at 07:03 PM.

#107

Once I get them back I will adjust the chambers to 31cc and then mill 2cc from the centre of the top of the pistons to get CR down to 11.0:1

#108

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

I meant there is 0.001" difference in diameter between the smallest and largest port diameter just before thew bowl. I need to adjust these so they are all the same.

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

never had a piston touch(but close enough to keep any carbon from buildup).

i know this dont mean dick!! but started studying squish/quench around 1962/63 when building a supercharged chevy dragster, at that time i had Mickey Thompson make some custom forged pistons for me, 8-1 comp. but low comp. chamber step on piston top, so the piston came very close to head.

that engine reved to 8300rpm, no problem.

must have worked went 200mph in 7.25 ET, 1965.

also almost NONE of your information was available in 1965, i probably would never have tried anything, and stayed home!

something like you,had to go ahead and do it!!!

The following users liked this post:

xjsv12 (12-15-2016)

#109

The following 2 users liked this post by warrjon:

Greg in France (12-16-2016),

xjsv12 (12-15-2016)

#110

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

I meant there is 0.001" difference in diameter between the smallest and largest port diameter just before thew bowl. I need to adjust these so they are all the same.

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

Before I do any work in the ports and bowls I will discuss with Norman as he has ported a lot of V12 heads.

I was reading an article on the V12 HE head and its SFC peaks at 2500rpm I think this is the high swirl design. Swirl = flow turbulence = less total air flow. So yes I think there is too much turbulence to make good power.

I will be sacrificing intake turbulence for increased flow. I am hoping that reducing the squish distance from about 0.090" to 0.040" will help a lot with part throttle cruise fuel consumption.

I have done a lot of measuring and the stock valves and seats should in theory support 533hp from the Wallace Racing calculator and the throat to valve is 86%. The restriction is definitely the port just before the bowl measured at 0.98". Again using the calculator this puts peak torque at 3000rpm, pretty close to 2800rpm quoted. This needs to opened to 1.1" to raise peak torque to about 4000rpm. This should make a good street engine especially with 6.7L capacity

flow past the inlet valve should be better ,because of the larger bore unshrouding the area close to the bore, allowing better flow between valve and bore. i like it!

a lot of people get lost in port and bowl air flow, without giving much thought to the air after it gets past the valve, i have actually put a notch in the cylinder bore above ring travel, just to relieve that flow area.

just another thought about subject.

Last edited by ronbros; 12-15-2016 at 07:10 PM.

The following users liked this post:

xjsv12 (12-15-2016)

#111

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

good idea, but the V12 Jag rod is super strong and stretch is unlikly, i'm thinkin good for 10,000revs, with good bolts!

i built my V12 in 1994/95, and using Euro. 9-1 pistons, so having measured clearance YIKES, .150 thousandths, pre HE, almost impossible to detonate!

a slight head mod put my comp. ratio around 9.2-1

but leaves a lot on the table, if i ever build a V12 again, Grp44 was around 13-1 on some of there engines.

and tons of newer engine ideas.

anyhow good luck!

The following users liked this post:

xjsv12 (12-15-2016)

#112

6.7L = 92mm bore x 84 stroke. Not sure I would do things this way nowadays but these are no doubt ex stock race parts.

I would do the stock 78mm stroke and the off the self 96mm for just about 6.8L. Better still drop the 2.3 pin down to 2.1 or 2.0 chevy to make 82 or 84 and let the piston stick out 2 or 3mm !!!!

HE head machined to take the 2-3mm full bore recess effectively unshrouding the inlet. Superior flow from the inlet + better clearance around the sides from the larger bore. Compression 'pocket' right at the exhaust & plug.

I would do the stock 78mm stroke and the off the self 96mm for just about 6.8L. Better still drop the 2.3 pin down to 2.1 or 2.0 chevy to make 82 or 84 and let the piston stick out 2 or 3mm !!!!

HE head machined to take the 2-3mm full bore recess effectively unshrouding the inlet. Superior flow from the inlet + better clearance around the sides from the larger bore. Compression 'pocket' right at the exhaust & plug.

The following 3 users liked this post by xjr5006:

#113

The following 3 users liked this post by warrjon:

#114

The following 2 users liked this post by xjsv12:

Jonathan-W (12-16-2016),

ronbros (12-16-2016)

#115

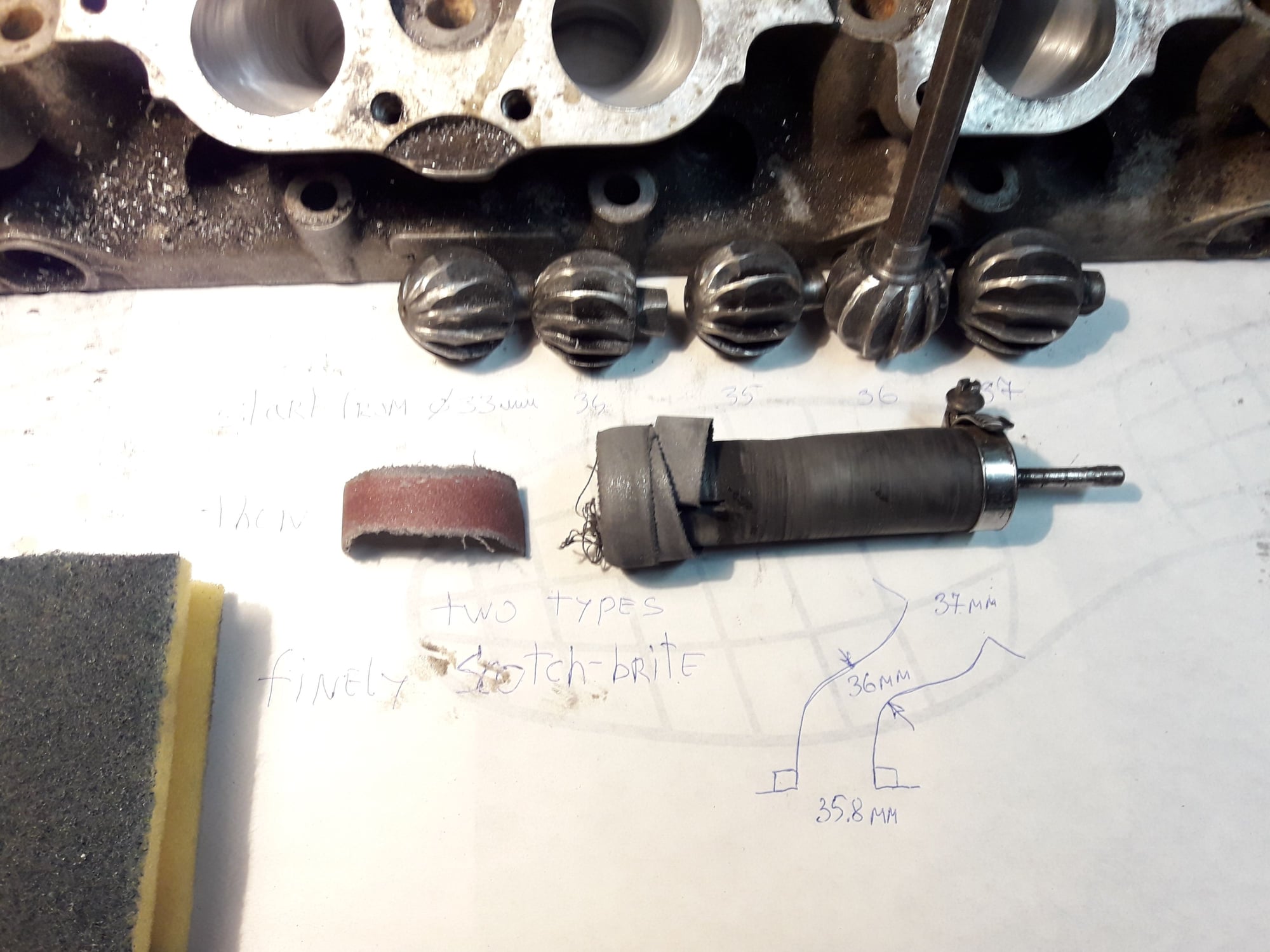

Lots of work there on both the chambering and the porting, looks like 36MM port? Group A spec? You realise I have the matching manifolds? 46 at plenum and 36 at the head or larger if you bore them.

I always finish with flap wheels gets the ports nice and round.

Next time I think I will just get the inlets bored for 2", saw this in the TWR build sheet and thought I had been silly for years doing things the hard way; so now you know.

I always finish with flap wheels gets the ports nice and round.

Next time I think I will just get the inlets bored for 2", saw this in the TWR build sheet and thought I had been silly for years doing things the hard way; so now you know.

#116

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

6.7L = 92mm bore x 84 stroke. Not sure I would do things this way nowadays but these are no doubt ex stock race parts.

I would do the stock 78mm stroke and the off the self 96mm for just about 6.8L. Better still drop the 2.3 pin down to 2.1 or 2.0 chevy to make 82 or 84 and let the piston stick out 2 or 3mm !!!!

HE head machined to take the 2-3mm full bore recess effectively unshrouding the inlet. Superior flow from the inlet + better clearance around the sides from the larger bore. Compression 'pocket' right at the exhaust & plug.

I would do the stock 78mm stroke and the off the self 96mm for just about 6.8L. Better still drop the 2.3 pin down to 2.1 or 2.0 chevy to make 82 or 84 and let the piston stick out 2 or 3mm !!!!

HE head machined to take the 2-3mm full bore recess effectively unshrouding the inlet. Superior flow from the inlet + better clearance around the sides from the larger bore. Compression 'pocket' right at the exhaust & plug.

sometimes i forget what i did 50years ago, that type mod was called a pop-up piston, head machined for piston to protrud up into it!

i had a Vtwin harley M/C, and on the barrels/jugs, machined 1.5mm from both top and bottom of barrel, that made the piston pop-up 3mm into head, 13/14 ratio and 108octane , worked very well won big bike drag race in (JeeZ,1957), damn im gettin old.!!!

#117

flow past the inlet valve should be better ,because of the larger bore unshrouding the area close to the bore, allowing better flow between valve and bore. i like it!

a lot of people get lost in port and bowl air flow, without giving much thought to the air after it gets past the valve, i have actually put a notch in the cylinder bore above ring travel, just to relieve that flow area.

just another thought about subject.

a lot of people get lost in port and bowl air flow, without giving much thought to the air after it gets past the valve, i have actually put a notch in the cylinder bore above ring travel, just to relieve that flow area.

just another thought about subject.

I used a lot David Vizard's tutorials to help me along the way. What I've done is keep it basic, ie work on the areas of max flow restriction. As I'm using stock cams there is no point in opening the bowls too much as the velocity in the cams useful range will drop too much.

I will open out the port where it pinches above the bowl, they are currently 29.5 to 30.3mm in diameter, these will opened to match them. from there the bowl to the seat opens out, so this will just be blended to remove the cutter ridges.

The following 4 users liked this post by warrjon:

#118

#119

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

The following 2 users liked this post by ronbros:

Jonathan-W (12-17-2016),

xjsv12 (12-20-2016)

#120

Spent today porting one head. Or should I say matching the port sizes. The largest is 30.3mm diameter just before the valve guide which I have increased slightly to 30.4mm and matched the rest. Not sure yet if I'll cut some of the valve guide away. I'll talk to Norman before I do this.

I have left the ports pretty well stock as I am using the stock camshafts. I have also started cleaning up the bowls. I didn't take photos of these today I'll do that tomorrow and post up some pics.

I have left the ports pretty well stock as I am using the stock camshafts. I have also started cleaning up the bowls. I didn't take photos of these today I'll do that tomorrow and post up some pics.

Last edited by warrjon; 12-18-2016 at 03:53 AM.

The following 3 users liked this post by warrjon: