Cherry Blossom - Restoration 1990 XJS V12

#2661

Hi Duke

If nothing else goes to prove that even the most expensive Car Cover is not always the best and one of these 'El Cheapo' ones stood up to a battering from Storm Franklin, which was the 3rd Storm in as many days and also very handy to have if you have just Polished your Car and don't want it covered in Tree Sap or Bird Droppings before you go out

If nothing else goes to prove that even the most expensive Car Cover is not always the best and one of these 'El Cheapo' ones stood up to a battering from Storm Franklin, which was the 3rd Storm in as many days and also very handy to have if you have just Polished your Car and don't want it covered in Tree Sap or Bird Droppings before you go out

The following users liked this post:

Greg in France (03-01-2022)

#2662

What Has He Gone And Bought Now!

The Ultimate 'Big Boys Toy' That's What

I've Gone And Bought Myself A Plasma Cutter!

No I don't know why either!The Ultimate 'Big Boys Toy' That's What

I've Gone And Bought Myself A Plasma Cutter!

Although maybe I do, as I love Hunting round the Scrap Yard for useful bits and pieces for my XJS which can take Forever to remove!

Especially if you have to resort to a FBH or some Spanners!

Though as I am so well in with these Guys, they let me use their 'Gas Axe' although more often than not the Pipes aren't long enough to reach but not so with my little 'Plasma Cutter' as I've got a long extension wire that can reach to almost anywhere then Plug the other end into their Shop

Where the Cheapest one on the Market that I purchased from a Supermarket Store, was only £149.99 and one of the reasons I chose it was because it had its own built in Compressor! which is seems that some of the slightly more expensive one's don't have

But this one by being self contained, means that you can pick it up plug it in and you are 'good to go' and though its only 40 Amps it plenty good enough for what I need and can very easily cut through 10mm Steel and probably even thicker than that, although I haven't really had a need to try that yet

Having never used one before, when I read the Manual, it sort of freaked me out as the Voltage generated is so high that it can be lethal if you get a shock and so I was quite nervous the first time that I switched it on, where it seems the Watchword is to not to do anything Stupid like using it out in the rain or in damp conditions

So once you've got your 'Sensible Head On' then everything should be fine, where in case I forget to mention it you should preferably wear a Self Darkening Full Face Welding Mask, as just like when you are Welding with Mig, you need to protect your eyes and also make sure that you don't end up getting you face Smattered with Sparks and Hot metal, which gets less as your 'Skill Set' increases

Where as with Mig Tig or Stick, it really is a Question of 'Practice Makes Perfect' as the 'Plasma Cutter' is just so versatile that you can use it for much more than hacking Cars to pieces to get that Vital Component you were after, like for instance Cutting Circles with an easy home made rig but more on that later, as when used in Freehand Mode you can very easily cut any Shape you want to

And maybe even turn yourself into a Metal Work Artist making decorative Gates or even some of those Bespoke House Numbers, which could be the ultimate side hustle, as Plasma Cutting is such fun to do, where apart from electricity and some cheap Consumables there really isn't anything else you need to buy

So here it is:

Wowser! what a lovely piece of Kit!

Its really pretty Simple as from Left to Right the Connections are as follows: (1) Main Electric Lead to the Torch through which Compressed Air also Flows (2) Cable to Trigger Switch (3) Earth Clamp

At the back of the Setup is the On/Off Switch, as well as a Connection for a Stand Alone Compressor should you want to Connect one, to provide you with the power to Cut Thicker Stuff, although for a Home User like me, the built in Compressor should be more than enough, although its always nice to have that option

Now onto the Consumables which are Cheap to buy:

Left to Right: (1) The Ceramic Cup seldom needs replacing unless it develops a Crack or you drop the Torch (2) The Electrode which can be turned round if one end wears out but lasts quite a long time

(3) The Ceramic 'Swirl Ring' (don't attempt to use it without this, as its also an insulator) (4) The Torch Nozzle these burn out fairly quickly, though a lot depends on your Skill and so you may need to replace them if the Hole in the Nozzle gets too big (hard to say how long they will last) so you may need to replace them after every job,although they are Cheap to buy and maybe even Cheaper than some Welding Rods

Next is how it all hangs together:

Electrode (double ended) then the Swirl Ring then the Cutting Nozzle: All held together on the Torch by the Screw it On Ceramic Head

Finally the Consumables, especially the Nozzle Jets which burn out fairly quickly though maybe less so as your Skill improves, so if you buy a Plasma Cutter its best to Order some spare Consumables at the very same time, as if the Nozzles are not 'On Point' every time you use your Plasma Cutter, then the Bottom Line is that it won't Cut properly if at all and could even burn out your machine

Though don't rush out and buy yourself a Plasma Cutter just yet, as there is something very interesting you should know! that could save you $$$ £££!

All will be revealed in the next Update!

The following 6 users liked this post by orangeblossom:

89 Jacobra (03-10-2022),

eurolat (03-11-2022),

Greg in France (03-11-2022),

LnrB (03-10-2022),

ptjs1 (03-10-2022),

and 1 others liked this post.

#2663

Adventures With My Plasma Cutter

Having The Best Of Both Worlds

'Not a lot of people know this' as Michael Caine might say but basically the are Two Types of Plasma Cutter to Choose from for the Hobbyist and Small Workshop userHaving The Best Of Both Worlds

HF Inverter and The 'Pilot Arc'

So what's the difference and which one is best

Opinions on this vary as it could be said that each one has and advantage depending on what you are using it for, though many people tend to choose the more versatile 'Pilot Arc' as at the budget end of the range they are only a few dollars more $50-$150 'Ballpark'

So what was it that decided me NOT to buy one?

My Number One Priority was I wanted something portable that I could carry around in the Trunk of my Car so I can go to my Scrap Yard, Plug it into there Workshop and then providing I had a long enough lead, then I would have something to Cut with for removing Spare Parts to go on my XJS or something that I could make use of in my Shop

So I chose a Budget Plasma Cutter of the HF Inverter type, for the Bargain Price of £149.99 from a well known UK Homestore as most importantly for me, this had a Built in Compressor with the Option to Connect it to a Stand Alone Compressor if I either wanted or I needed to for the purpose of Cutting Thicker Materials, which often needs more Air Rather than Amps

Where many of the 'Pilot Arc' Models use an External Compressor, which for me would have defeated the object of the exorcise that I was after

So in case you may be wondering what is the Main difference between The HF Inverter and 'The Pilot Arc' it is basically this:

The HF Inverter most Normally uses a 'Drag Tip' on the Torch, which needs to be Kept in Contact with the Steel that you are Cutting in order to maintain the Cutting Arc

Which is a Whopping 22,000 degrees Centigrade!

This works Fine on nice Clean Steel but if you're Cutting something Rusty or something with a Coating like for instance Powder Coating or some sort of Paint, then you could run into problems maintaining that Arc or even getting it Started in the First Place

And this is where 'The Pilot Arc' comes into its own because unlike the HF Inverter which does nothing until it actually comes in Contact with the Steel and the Trigger is pulled

'The Pilot Arc' has another Trick up its Sleeve, because as soon as you Pull the Trigger, regardless of whether the Tip is in Contact with the Workpiece or NOT 'The Plasma Arc' will literally Shoot Straight out of the Gun Nozzle, like a Lightning Bolt, which when it happens the First Time could Scare the Heck out of You like it did do to me

Where just in Case you need reminding is a very HOT! 22,000 degrees Centigrade! so don't have your hands or anything else in the way for obvious reasons, as it makes an Oxy Acetylene Torch look a bit tame in comparison and so you need to be Careful and have your 'Common Sense Head On' at all times including a Full Face Welding Shield or you could be blinded or get Arc Eye from the Flash

That the First Time will be sudden and very unexpected and could well mean a Change of Underwear!

Where the 'Lightning Bolt' from the Cutting Tip will Shoot Out every time you pull the Trigger, which can be very scary till you get the hang of it and what you're doing and when you start to Cut with it, be prepared for lots of Sparks and Molten Metal flying everywhere, so that is why I use a Full Face Automatic Welding Mask

Once you've had some practice you can reduce the Sparks but don't get overconfident and start to take unnecessary chances!

Especially with 'The Pilot Arc' where the Tip can either be dragged across the Metal like the HF Inverter or kept about 5mm off the Surface where you can buy a 'Stand Off' Clip On Fitting to help maintain that distance, if you're not using it Freehand for something like Cutting OFF a Bolt or wanting to Hack something off

Which is what I wanted to do, so as you can imagine I was really missing not having 'Pilot Arc'

But then I had an idea!

The following users liked this post:

Greg in France (03-15-2022)

#2664

Adventures With My 'Plasma Cutter'

Having The Best Of Both Worlds

My idea was to find someone who had a Plasma Cutter with the 'Pilot Arc' that my Plasma Cutter doesn't have and then decide if having that feature was worth the extra £150 that seems to be the approximate extra 'Ball Park' Figure for a 40 Amp Plasma Cutter, which seems to be the most popular size for the DIY user or Home Work Shop and I only Paid £149.99 for mine and that has a built in CompressorHaving The Best Of Both Worlds

This was a very important feature for me, so that it would be portable and easy to carry around, in case I needed to get some parts for my XJS or use it in one of the garages at 'Orange Blossom Towers' where maybe your first Question might be, 'how easy is it to use?'

The answer to that being not much less than a Quick 'Walk in the Park' as the Plasma Cutter cuts Metal like a 'Knife Through Melted Butter' and does so at a Lightening Speed that will come as a Big Surprise, in the event that you may never have used one before

Where if you use a Metal Straight Edge 1/4 in Flat Bar the Torch will give you a Precision Cut, which can be so accurate that you wouldn't even have to grind the edge, although it certainly wouldn't do any harm to Buzz it with a Flap Wheel on your Angle Grinder, just to clean off any bits of 'dross'

So Basically what you do, is to plug in your 'Plasma Cutter' then Clip the Earth Wire to your Workpiece and then you are 'Good to Go' not forgetting your Automatic Face Mask (which isn't supplied with the Kit) where it is very important to use all your PPE as when you Pull the Trigger on your Plasma Cutter, you do need to protect yourself against the Blinding Flash! when the Arc Starts

As this is much Brighter and also more intense, than you might be use to when Mig Welding and in case I forget to mention it a Massive Shower of Sparks when the Arc Starts and so another very good reason to use a Full Face Helmet to protect yourself from that

So lets suppose you've got your Piece of Metal and you have marked out the Shape you want to Cut, where for the sake of example, we could say a 'Straight Line' with your Straight Edge 1/4 in Flat Bar, Clamped to the Surface

You can do a couple of Dummy Runs, with the Plasma Cutter Switched off at this stage, so that you can get the feel of how you are going to move the Torch when you are ready to make your very first Cut, which is best done on a Piece of Scrap Plate, until you get a feel for what you are doing

Where according to those I have spoken to, its more about the Speed you move the Torch, which will be either Slow or Fast depending on the Thickness of the Metal you are Cutting rather than to keep adjusting the Amps, although of course you can do it that way if you want, as it is much more a Question of Trial and Error

Also don't forget to wear your protective gloves, as that Plasma Flame burns at an Astonishing 22,000 degrees Centigrade, so keep your Fingers and anything else well out of the way and treat the Plasma Cutter with the maximum respect whenever you use it

So when you are finally ready to go and have your PPE on and have Switched on the Plasma Cutter, where you will hear it Boot Up, lower the Tip of the Torch down on to the Steel you are Cutting and then Psych yourself up for the moment when you Pull the Trigger, as it almost certainly going to make you jump in surprise the first time you use it

Where unlike an Oxy Acetylene Torch, you need to keep the 'Drag Tip' in Contact with the Workpiece all the time, unlike with the 'Pilot Arc Cutter' where you have more flexibility with that, then once the Arc has Started then pull the Plasma Cutter Torch down the Side of the Straight Edge as you make the Cut, which will be so fast and accurate, that its just like cutting paper with a Pair of Scissors

Of course you are not limited to just Cutting Straight Lines, as you can cut out any Shape you want to, as your skill level increases, including Circles, which seem to come in useful for all sorts of Stuff and in my next Update I'll show you how I made a Circle Cutter for almost next to nothing, that also has a useful Magnetic Base

Having had the Chance to Compare my Non Pilot Plasma Arc Cutter, to a Plasma Arc Cutter with the 'Pilot Arc' Feature, where the Arc is Fully Active from the Moment you Pull the Trigger, whether it is in Contact with the Workpiece or not, I came away thinking I didn't really need it, as in the very short Video I'm cutting a piece of very rusty Steel

Also I feel that the Pilot Arc feature could sometimes prove to be dangerous, as if you were underneath something and reaching around as you tried to pick up the Torch and accidentally went and touched the Trigger, before you knew what was happening that Ultra Hot Flame would shoot out of the end of the Torch, which could easily leave you with 3rd degree burns or even worse!

Though as a piece of Workshop Kit, I think you might possibly wonder how you ever managed without one

Although I think I will be even more nervous when I get to take a look at my Electric Bill

The following 2 users liked this post by orangeblossom:

Greg in France (03-27-2022),

ptjs1 (03-26-2022)

#2665

My idea was to find someone who had a Plasma Cutter with the 'Pilot Arc' that my Plasma Cutter doesn't have and then decide if having that feature was worth the extra £150 that seems to be the approximate extra 'Ball Park' Figure for a 40 Amp Plasma Cutter, which seems to be the most popular size for the DIY user or Home Work Shop and I only Paid £149.99 for mine and that has a built in Compressor

But if you have the funds available to move up to the better model and you're debating yourself if you should or not, then remember that buying the higher priced one will cause you to buy once and cry once. Right now you're facing a situation where you might have to buy twice and cry twice - selling the old one for a loss and buying the more expensive one.

In watching your video it's easy to see the difficulty you're having getting the arc started. I'd guess that an pilot arc unit would pay for itself in frustration avoidance.

Also, as someone who owns a pilot arc plasma cutter - are you sure that's the best tool to take to a junkyard to cut pieces off cars? I'd take a nice battery powered Sawzall (reciprocating saw) with a couple of carbide blades.

The following 3 users liked this post by Thorsen:

#2666

Hi Thorsen

While I really do agree with almost everything that you have said, the object of the exercise in my own case anyway was get up and go portability, which is sometimes lacking in the more expensive machines that often require a stand alone Compressor, that my Plasma Cutter has built in

And though I could afford to buy a much better one, in my own experience one of the more expensive ones is not always the best as I won't be using it that often but mainly for taking occasional trips to the Scrap Yard for picking up suitable pieces of Steel for making things like Jack Stands as well as some Car Ramps for my XJS

Had I been cutting that Steel for real instead of just for a demo, then I would have nicked the end of it with an Angle Grinder, to make the Arc much easier to Start, although in that Video I do have to 'Fess Up' and say the Arc was hard to Start because I forgot to take the Safety Catch OFF!

In this Second Video, you can see I'm Cutting up the Rustiest piece of Steel that I could find, where this time using a Pilot Arc Torch proved to be an advantage, though most of the time the 'drag tip' would be good enough to do the jobs I need

While I really do agree with almost everything that you have said, the object of the exercise in my own case anyway was get up and go portability, which is sometimes lacking in the more expensive machines that often require a stand alone Compressor, that my Plasma Cutter has built in

And though I could afford to buy a much better one, in my own experience one of the more expensive ones is not always the best as I won't be using it that often but mainly for taking occasional trips to the Scrap Yard for picking up suitable pieces of Steel for making things like Jack Stands as well as some Car Ramps for my XJS

Had I been cutting that Steel for real instead of just for a demo, then I would have nicked the end of it with an Angle Grinder, to make the Arc much easier to Start, although in that Video I do have to 'Fess Up' and say the Arc was hard to Start because I forgot to take the Safety Catch OFF!

In this Second Video, you can see I'm Cutting up the Rustiest piece of Steel that I could find, where this time using a Pilot Arc Torch proved to be an advantage, though most of the time the 'drag tip' would be good enough to do the jobs I need

Last edited by orangeblossom; 03-27-2022 at 05:39 PM.

The following users liked this post:

Thorsen (03-27-2022)

#2667

Guys

I am confused, I understand drag tip = keeping the end of the cutter touching the work, right?

But I do not graspdrag tip pilot thingy and what the differences are between the two, and whether a drag tip can be turned into a pilot arc or not!

At the start of the video, AJ, why does the torch give a flame/arc when it is not touching anything?

I am confused, I understand drag tip = keeping the end of the cutter touching the work, right?

But I do not grasp

At the start of the video, AJ, why does the torch give a flame/arc when it is not touching anything?

Last edited by Greg in France; 03-28-2022 at 02:45 AM.

#2668

Hi Greg

With a 'Bog Standard' HF Plasma Cutter, such as the 'el Cheapo' one I have £149.99 from a well known UK Home Store, what is known as the 'Drag Tip' needs to be kept in Contact with the Work Piece to maintain the Plasma Cutting Arc

Which works well on nice Clean Steel and to a Certain extent on Rusty Steel as well, though if you want the Perfect Cut with very little 'Dross' then it may help to Flash it over with a Flap Wheel before you Start Cutting, although it isn't always necessary to do so

The Pilot Arc Plasma Cutter is a little bit different, as it doesn't initially need to be in Contact with the Work Piece, as all you do is Pull the Trigger and the Plasma Arc Lights up all on its own, so if for instance you were Cutting a Piece of Painted Steel or something with a Non Conductive Coating (ie) Powder Coating or an Ultra Rusty Piece of Steel like in the Second Video

Then a Standard Non Pilot Arc Plasma Cutter 'Might' just have a problem getting Started, where you could overcome this by just Flashing the first point of Contact with an Angle Grinder or something like that, or if you want all the 'Bells and Whistles' like you might get on a more expensive Machine, then you could get yourself a 'Pilot Arc Plasma Cutter'

Where the 'Tip' doesn't need to be in Contact before the Plasma Arc Lights up and as such can more easily cut through Coated Surfaces as well as Very Rusty Ones as shown in the Second Video

Think of a Pilot Arc Cutter, in the same way that you would Drill a Small Pilot Hole in a Piece of Steel, before you use a Bigger Drill Bit to make that Small Hole Bigger (same sort of principle to that applies)

Except that in Both Videos, I am using exactly the same Non Pilot Arc Plasma Cutter

As once I got my head around the way that a Pilot Arc Cutter works, all I did was do a 'Mod' to the Plasma Arc Cutting Torch, so now I've got 'The Best of Both Worlds' in as much as I can now use my very inexpensive Standard Plasma Cutter, with or without Pilot Arc depending on the Job that I am doing

Though as this 'Mod' is still in the 'Experimental Stage' it could among some other things burn out your Machine!

Which is why I'm not revealing how I did this 'Mod' except to say 'DON'T COPY ME' and 'DON'T TRY THIS AT HOME!' as it could be potentially dangerous to do so!

No need to do so anyway, as I am now working on another 'Mod' that is much Safer, although in order to do so I've got to get a few more bits and pieces

As for me whenever possible I much prefer using the Standard Plasma Cutter with the 'Drag Tip' as in all sorts of ways its much safer, just in case you accidentally pull the Trigger when you don't mean to and it goes off in your hand

Thorsen and Greg, I could send you both a PM of my 'Mod' if you like, although because its just an experiment, it would be irresponsible to publish any details on the Forum at this stage

So as I have already said Don't Copy anything I've done and 'DON'T TRY THIS AT HOME'

With a 'Bog Standard' HF Plasma Cutter, such as the 'el Cheapo' one I have £149.99 from a well known UK Home Store, what is known as the 'Drag Tip' needs to be kept in Contact with the Work Piece to maintain the Plasma Cutting Arc

Which works well on nice Clean Steel and to a Certain extent on Rusty Steel as well, though if you want the Perfect Cut with very little 'Dross' then it may help to Flash it over with a Flap Wheel before you Start Cutting, although it isn't always necessary to do so

The Pilot Arc Plasma Cutter is a little bit different, as it doesn't initially need to be in Contact with the Work Piece, as all you do is Pull the Trigger and the Plasma Arc Lights up all on its own, so if for instance you were Cutting a Piece of Painted Steel or something with a Non Conductive Coating (ie) Powder Coating or an Ultra Rusty Piece of Steel like in the Second Video

Then a Standard Non Pilot Arc Plasma Cutter 'Might' just have a problem getting Started, where you could overcome this by just Flashing the first point of Contact with an Angle Grinder or something like that, or if you want all the 'Bells and Whistles' like you might get on a more expensive Machine, then you could get yourself a 'Pilot Arc Plasma Cutter'

Where the 'Tip' doesn't need to be in Contact before the Plasma Arc Lights up and as such can more easily cut through Coated Surfaces as well as Very Rusty Ones as shown in the Second Video

Think of a Pilot Arc Cutter, in the same way that you would Drill a Small Pilot Hole in a Piece of Steel, before you use a Bigger Drill Bit to make that Small Hole Bigger (same sort of principle to that applies)

Except that in Both Videos, I am using exactly the same Non Pilot Arc Plasma Cutter

As once I got my head around the way that a Pilot Arc Cutter works, all I did was do a 'Mod' to the Plasma Arc Cutting Torch, so now I've got 'The Best of Both Worlds' in as much as I can now use my very inexpensive Standard Plasma Cutter, with or without Pilot Arc depending on the Job that I am doing

Though as this 'Mod' is still in the 'Experimental Stage' it could among some other things burn out your Machine!

Which is why I'm not revealing how I did this 'Mod' except to say 'DON'T COPY ME' and 'DON'T TRY THIS AT HOME!' as it could be potentially dangerous to do so!

No need to do so anyway, as I am now working on another 'Mod' that is much Safer, although in order to do so I've got to get a few more bits and pieces

As for me whenever possible I much prefer using the Standard Plasma Cutter with the 'Drag Tip' as in all sorts of ways its much safer, just in case you accidentally pull the Trigger when you don't mean to and it goes off in your hand

Thorsen and Greg, I could send you both a PM of my 'Mod' if you like, although because its just an experiment, it would be irresponsible to publish any details on the Forum at this stage

So as I have already said Don't Copy anything I've done and 'DON'T TRY THIS AT HOME'

The following users liked this post:

Greg in France (03-28-2022)

#2669

Thanks AJ. One more question: the pilot arc, where does the flame come from if it is not touching anything to make an electric arc?

Just looked it up, the Pilot Arc has an earth inside the torch head itself, so does not need the earth on the work to make the circuit.

Just looked it up, the Pilot Arc has an earth inside the torch head itself, so does not need the earth on the work to make the circuit.

Last edited by Greg in France; 03-28-2022 at 03:04 AM.

The following users liked this post:

orangeblossom (03-28-2022)

#2670

Hi Greg

Close but No Cigar!

You still need an Earth to the Work Piece, if you want for instance to Cut a Piece of Steel, or all you will have is a Plasma Arc Flame at the end of the Plasma Arc Torch like a glorified Blow Lamp!

And just in case you are wondering if you can use it as a Blow Lamp, the Answer is 'Probably Not' except for a very short time, as you are not meant to use it for that and you 'Could' burn out the Wiring in the Handle of the Torch and maybe even the Machine itself

The Reason Being the 'Pilot Arc Flame' is there to get the Arc Started on the Work Piece, then when the Tip of the Torch makes actual Contact (or close enough for the Arc to Jump over) then the Tip of the Torch takes over to complete the Circuit, rather than putting an excess load on the Wiring inside

In Simple Terms it then reverts back to a Normal Non Pilot Arc Cutter to Finish the Job

As for the Actual Torches themselves, (Plasma Arc Cutter or Plasma Pilot Arc Cutter) the way that they are Wired up is quite different and absolutely shouldn't be messed about with, not unless you've got some sort of 'Death Wish'! and that includes the Wiring in the Machine itself

So that wasn't what I did

Although regardless of whether your Plasma Arc Cutter is fitted with the Pilot Arc feature or Not, you still need an Earth to the Work Piece, or all you will end up doing is heating the Metal and also possibly burning out the Wiring of not only the Plasma Arc Torch but also the Plasma Arc Cutter Machine itself

Under No Circumstances should you attempt to interfere with the Wiring inside the Plasma Arc Torch! or the Machine! YOU HAVE BEEN WARNED! So just don't do it or even be Tempted to do so!

My idea was really simple and took 30 Seconds to do! and didn't involve any Changes to the Wiring

Though since it was an Experiment, it would be irresponsible to show you what I did, so please hang on to see the Mark 2 Version which is so much Safer than the Mod I did for myself

'Greg' I better PM you, as we do not want to lose a Forum Legend!

Close but No Cigar!

You still need an Earth to the Work Piece, if you want for instance to Cut a Piece of Steel, or all you will have is a Plasma Arc Flame at the end of the Plasma Arc Torch like a glorified Blow Lamp!

And just in case you are wondering if you can use it as a Blow Lamp, the Answer is 'Probably Not' except for a very short time, as you are not meant to use it for that and you 'Could' burn out the Wiring in the Handle of the Torch and maybe even the Machine itself

The Reason Being the 'Pilot Arc Flame' is there to get the Arc Started on the Work Piece, then when the Tip of the Torch makes actual Contact (or close enough for the Arc to Jump over) then the Tip of the Torch takes over to complete the Circuit, rather than putting an excess load on the Wiring inside

In Simple Terms it then reverts back to a Normal Non Pilot Arc Cutter to Finish the Job

As for the Actual Torches themselves, (Plasma Arc Cutter or Plasma Pilot Arc Cutter) the way that they are Wired up is quite different and absolutely shouldn't be messed about with, not unless you've got some sort of 'Death Wish'! and that includes the Wiring in the Machine itself

So that wasn't what I did

Although regardless of whether your Plasma Arc Cutter is fitted with the Pilot Arc feature or Not, you still need an Earth to the Work Piece, or all you will end up doing is heating the Metal and also possibly burning out the Wiring of not only the Plasma Arc Torch but also the Plasma Arc Cutter Machine itself

Under No Circumstances should you attempt to interfere with the Wiring inside the Plasma Arc Torch! or the Machine! YOU HAVE BEEN WARNED! So just don't do it or even be Tempted to do so!

My idea was really simple and took 30 Seconds to do! and didn't involve any Changes to the Wiring

Though since it was an Experiment, it would be irresponsible to show you what I did, so please hang on to see the Mark 2 Version which is so much Safer than the Mod I did for myself

'Greg' I better PM you, as we do not want to lose a Forum Legend!

The following users liked this post:

Greg in France (03-28-2022)

#2671

#2672

INSIDE AN XJS FUEL PUMP

Ok so I got a bit bored. as you do in between Tea Breaks and the GF extolling the Virtues of her Brand New Washing Machine, as the one that I made from our Concrete Mixer wasn't quite 'Cutting The Mustard' as much as Cutting Her Clothes and simply wouldn't have it that these were teething troubles that just needed ironing out (no pun intended) although on Second thoughts 'may be there was!'So sensing She might have revenge on her mind and self preservation on mine!

The only sensible option was to take the moral high ground and but her a Brand New Washing Machine with enough 'Bells and Whistles' to keep her amused for hopefully hours while I got on with the 'Boy Stuff' of getting the XJS prepped for the Summer, in the hope Fuel Prices may go down, although I've seen no signs of this at the moment

Where as I was having a Tidy Up, I came across a couple of old Fuel Pumps

One of which was from a V12 and the other from my AJ16 4.0L Six Cylinder

The latter of which was fitted with the dreaded In-Tank Fuel Pump, that though great while it's working, is a Total PIA Job, if it should ever go wrong as sooner or later, like anything else they will eventually do and if and when that happens, then you have a problem of epic proportions on your hands, as in order to replace it then the Tank must come out

Or at lease have to be pulled back, enough to get the old pump out and a New one in, where having had to do this job myself on two occasions, I would say this is the job from Hell as while it looks quite easy on the face of it, there is a lot more to it than there looks!

Which can be backed up by the fact that one of our Forum Members was quoted over $2,000 to do this very job, as it is so labor intensive and bear in mind that Shops have all the Tools and Facilities that us DIY Guys may not have, as for one thing a Car Lifter would certainly make this job so much easier, as to get to the Fuel and Return Pipes you have to reach right through the Cage!

Not so with the Pre-Facelift XJS V12 where the Fuel Pump for one of these Cars can be changed by the side of the road in around an hour

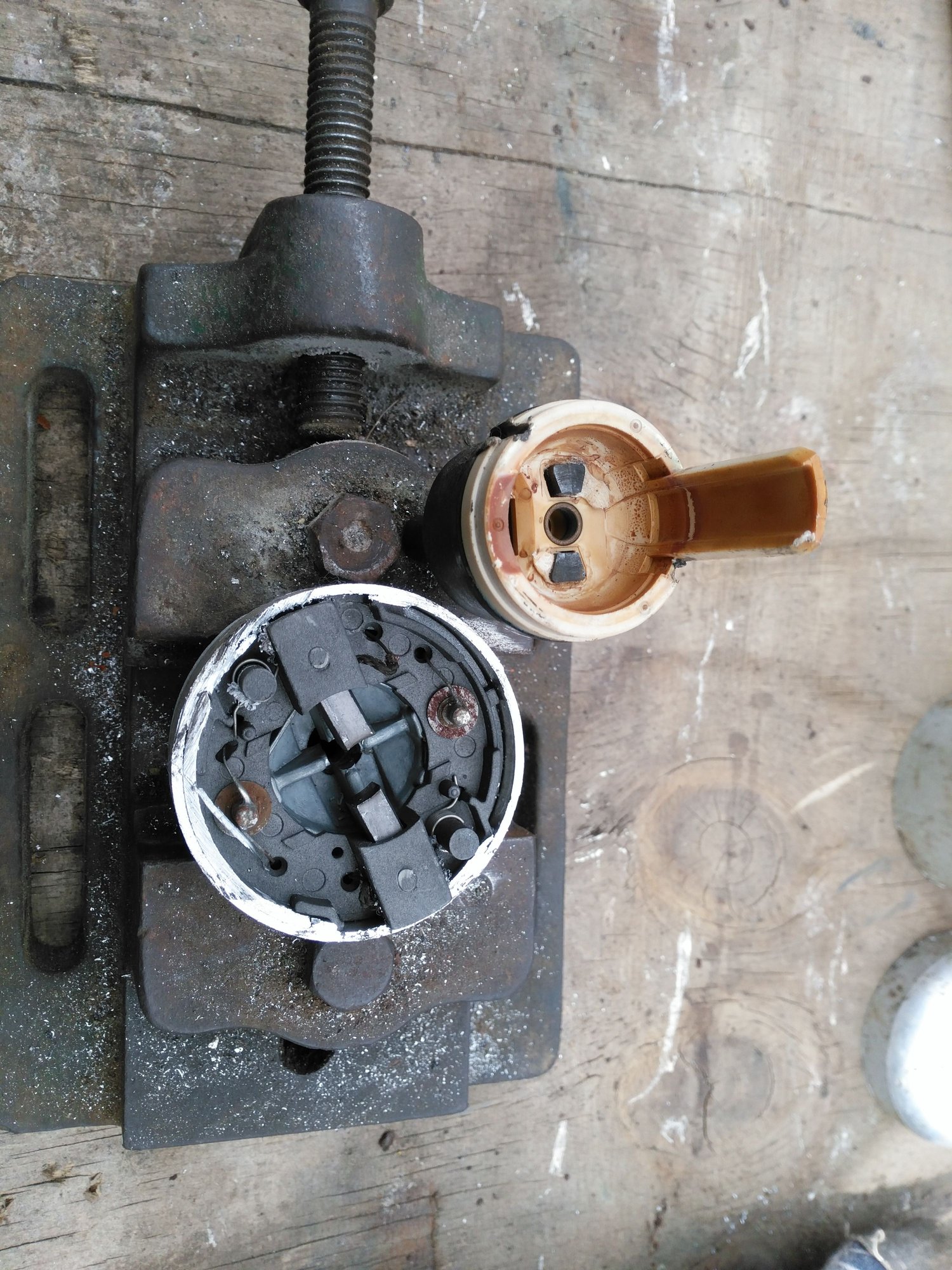

So having found these Two old Pumps and before I threw them away, I decided to Cut them both in half to see what was inside and how different they were

As while the Pump from the V12 is built like a Brick Out House the In-Tank Fuel Pump couldn't be more different and so its a No Brainer as to which one I'd prefer to be Pumping the Fuel in my Car

Built like a Brick Out House! the External Fuel Pump from an XJS V12

Solid as a Rock and Built to last

The Simply Massive Motor Core of the External Fuel Pump from an XJS V12

Looking somewhat light weight in comparison, the Internal Fuel Pump from an XJS 4.0L in line six

Me thinks the In-Tank Fuel Pump is nowhere near as Heavy Duty in Construction

A Pictures Worth A Thousand Words! Give me an External Fuel Pump on any day of the Week as its very easy to replace if it goes wrong while replacing the In-Tank Fuel Pump is a Nightmare!

The following 2 users liked this post by orangeblossom:

Greg in France (04-12-2022),

LnrB (04-12-2022)

#2673

Join Date: Mar 2014

Location: Tehama County, California, USA

Posts: 25,445

Received 9,208 Likes

on

5,386 Posts

The following users liked this post:

orangeblossom (04-12-2022)

#2674

#2675

Join Date: Mar 2014

Location: Tehama County, California, USA

Posts: 25,445

Received 9,208 Likes

on

5,386 Posts

The following 2 users liked this post by LnrB:

orangeblossom (04-13-2022),

ronbros (04-13-2022)

#2676

Hi LnrB

My Bad, I wasn't sure what you meant by 'Picture' as I thought you may be referring to a 'Picture' as in 'Photograph'

Though in any event it doesn't sound as if it would be too difficult to do a Conversion, which is what I will be doing if the Fuel Pump on my 4.0L ever packs up again, as its much too much of a PIA to replace it

My Bad, I wasn't sure what you meant by 'Picture' as I thought you may be referring to a 'Picture' as in 'Photograph'

Though in any event it doesn't sound as if it would be too difficult to do a Conversion, which is what I will be doing if the Fuel Pump on my 4.0L ever packs up again, as its much too much of a PIA to replace it

The following users liked this post:

ronbros (04-13-2022)

#2678

#2679

Join Date: Mar 2014

Location: Tehama County, California, USA

Posts: 25,445

Received 9,208 Likes

on

5,386 Posts

Though in any event it doesn't sound as if it would be too difficult to do a Conversion, which is what I will be doing if the Fuel Pump on my 4.0L ever packs up again, as its much too much of a PIA to replace it

After that, only very basic plumbing and electrical and, Shazaam, all done.

I never had a vapor lock with that setup either.

(';')

The following users liked this post:

orangeblossom (04-14-2022)

#2680

Converting My Standard HF Plasma Cutter

Into A Pilot Arc Cutter

So what's the Big difference and why would I want to do that?Into A Pilot Arc Cutter

Apart from the Cost of a Pilot Arc Plasma Cutter, which can cost appreciatively more than a Standard HF (High Frequency) Plasma Cutter, it has to be said that the Pilot Arc has a number of Advantages apart from the Cost of Consumables like the Plasma Cutting Tips, which although a bit more expensive that the Tips for a Standard HF Plasma Cutter, tend to last quite a bit longer as they don't contact the 'Work Piece'

Unlike they do on a Standard Plasma Cutter, where the Cutting Tip needs to remain in Contact with the 'Work Piece' to maintain the Plasma Arc to Cut the Steel and so is often referred to as a 'Drag Tip' where they do not last for ever and as such may need changing after every job, that can be a bit of a movable feast, depending on what you are cutting

In this respect the Pilot Arc works on a somewhat different principle as the Cutting Tip does not need to make Contact with the Metal that you are Cutting, though can also be used as a drag tip in certain situations though why would you ever want to, if you can avoid it as the 'Pilot Arc' Cutter is really such a brilliant piece of Kit, that you may well start to wonder how you ever managed to do without one

Super Silent in comparison with an Angle Grinder and can Cut through Steel like a Knife through Butter and even more so with the 'Pilot Arc' Feature, as because it pre-melts the Metal. it can Cut through Steel so fast, that you may have a job to keep up

Where unlike the Standard HF Plasma Cutter, that can sometimes struggle with very Rusty Steel or even Painted or Powder Coated Surfaces, The Pilot Arc Flame sails through them as if they were not there, as unlike the Standard HF Plasma Cutter, where the Tip needs to Contact the 'Work Piece' in order to 'Strike the Arc' as well as to Maintain it

With the 'Pilot Arc' Cutter, you just pull the Trigger and go! as the Plasma Cutting Arc is there right from the Start and also doesn't need to touch the 'Work Piece' in order to do so just 'Pull the Trigger and its there!'

Which ever Plasma Cutter you have, you will also need to use it with some PPE like a Full Face Welding Mask and preferably an Automatic one and also a Pair of Welding Gloves, so you don't burn your Fingers!

Quite possibly one of the Cheapest Plasma Cutters I have ever seen, although you can feel the Quality is there and as such have a reputation for very simply 'Flying off the Shelves!' as such I got up early and was the First in the Queue, which quickly turned into a 'Feeding Frenzy' where there were all Sold out in literally just a couple of Minutes and at a Bargain Price of £149.99

And nobody loves a Bargain more than me! especially as this Model was so small and Compact and even had its own built in Compressor for the 'Grab it and Go' Portability that I wanted, for going round the Scrap Yards to get pieces of Steel to make things that I could use for my XJS like for instance Axle Stands as well as all kinds of Stuff like that

This was a Standard HF Plasma Cutter with a Basic PT 31 Torch that has a 'Drag Tip' and although it wasn't Pilot Arc it was ideal to use for Cutting Circles with the Home Made Circle Cutting Jig I made

Though even better I had a Plan to Convert my Standard HF Plasma Cutter into a Pilot Arc one, which it turned out was easier than some out there may think, as apart from a very small 'Hack' the only thing you needed was to get a 'Pilot Arc' Torch to do the Conversion, which in case your wondering Cost 'Peanuts!'

What is in the Box?

An All Singing And Dancing 'Plasma Pilot Arc Torch' for only £34.99 Amazing Value for Money as this is a Semi Professional and Very Popular AG60 Model, just requiring the Ceramic Shroud to be Screwed on and also comes with Stand OFF Guides and a couple of Spare Cutting Tips

Using the Stand off Guides is optional but come in very handy for when making a long Straight Cut alongside a 'Straight Edge' as the Cutting Tip on a 'Pilot Arc' Torch does not need to touch the 'Work Piece' in order to Strike the Plasma Arc

Just Pull the Trigger and the Arc is there!

'Head to Head' The Basic PT31 Torch and the 'Uber Wonderful' AG 60 Pilot Arc Cutter!

So what makes these Two different and how can you use a 'Pilot Arc' Torch with a Standard Plasma Cutting Machine!

Well apart from an extra Earth Wire! that really is just about the only real difference there is! Not forgetting all the money that you could Save yourself which could easily be a couple of hundred pounds! where my Total Expenditure so far was £149.99 + £34.99p for the Pilot Arc Plasma Torch = £184.98

That even gave me more than enough to buy some Extra Consumable and some Self Darkening Glasses that only Cost £10.99 that will be very useful for all those awkward places, where a Welding Helmet is too big to fit

Spare Tips and Electrodes for the Standard Plasma Cutter PT 31

Spare Tips as well as Stand-Off Guides for the AG60 Plasma Pilot Arc Cutter (a little bit more expensive but supposedly longer lasting) as the Tips don't touch the Steel

In Simple Terms that Extra Earth Wire is the Only difference! (The Red Wire in the Photo)

As when you pull the Trigger on the 'Plasma Pilot' Arc Torch, this Extra Earth Wire excites the Plasma Arc (its really that simple) although the 'Work Piece' you are Cutting will also need Grounding as well

Wiring it up only requires a very Simple Hack and details of how to do so will be in my Next Update, though would have been much sooner were it not for a 3 day Arctic Storm plus all the details of how I made a Simple but very effective Circle Cutter

Self Darkening Glasses £10.99 should come in very useful to see into tight spaces where a Full size Welding Helmet is too big

The following 4 users liked this post by orangeblossom: