Front Spring Tool

#1

Hey guys, Iím tackling the front spring job using the genuine Jag tool.

But the tool doesnít come with instructions, and the book doesnít spell it out either, other than the diagram. Itís mostly self-explanatory but I donít want to make assumptions with something this potentially dangerous.

Have a couple questions in these two videos:

But the tool doesnít come with instructions, and the book doesnít spell it out either, other than the diagram. Itís mostly self-explanatory but I donít want to make assumptions with something this potentially dangerous.

Have a couple questions in these two videos:

Last edited by MrAndersonGCC; 02-17-2022 at 10:49 PM.

#2

MrAndersonGCC,

Please forgive me if I'm completely mis-seeing this, but I wonder if you've got the lower wedge plate on upside down on the tool, when fitted to the lower spring plate, compared to the pic of it in the workshop manual? I might well be wrong, as it's 10 years since I last used the tool!

As a suggestion, if you get stuck, the Jaguar Enthusiasts Club has a number of technical advisers in the UK. One of those is Ken Jenkins who runs the following: Ken Jenkins Jaguar Specialists - Classic Jaguar Spares (ukjag.co.uk)

I know you're probably not a JEC member and it may be difficult to describe over the phone, but if you're still stuck, try giving him a polite ring, say I sent you (Paul Sinnott) and he's a really knowledgeable guy who has been using the tool for years.

Good luck

Paul

Please forgive me if I'm completely mis-seeing this, but I wonder if you've got the lower wedge plate on upside down on the tool, when fitted to the lower spring plate, compared to the pic of it in the workshop manual? I might well be wrong, as it's 10 years since I last used the tool!

As a suggestion, if you get stuck, the Jaguar Enthusiasts Club has a number of technical advisers in the UK. One of those is Ken Jenkins who runs the following: Ken Jenkins Jaguar Specialists - Classic Jaguar Spares (ukjag.co.uk)

I know you're probably not a JEC member and it may be difficult to describe over the phone, but if you're still stuck, try giving him a polite ring, say I sent you (Paul Sinnott) and he's a really knowledgeable guy who has been using the tool for years.

Good luck

Paul

The following users liked this post:

MrAndersonGCC (02-18-2022)

#3

Starting at the top of the tool.

- You have the slotted round locking piece that locks into the top of the tool correctly in place. It does not matter at all the front to back orientation of it, as long as it is securely slotted home into the flats in the rod sticking up though the subframe spring tower. Flat side of the locking piece upwards.

- The bottom: The piece that you have in place against the spring pan is not orientated correctly. If you look carefully at one side of it you will see two machined out parts; these are to allow that piece to sit over the two short studs and nuts that hold the lower bump stop to the spring pan. Once they are correctly over it, that part will sit flat against the spring pan. It is deliberately wedge shaped to ensure, once it is in place properly, that the central tightening rod is pulling straight against the spring top. Without the wedge, the angle of pull would be off, as the bottom of the spring in the spring pan is NOT parallel with the spring top once the suspension is no longer compressed by the weight of the car.

- Next, after the piece described in 2, the mushroom shaped domed bit comes next, the domed bit upwards allows the apparatus to adjust to angle changes as you undo/do it up. A smear of grease on the dome does no harm.

- The tubular spacer comes next, this is needed on the XJS or the rod can run out of thread on tightening.

- Those studs are NOT for the two nuts you pointed to. These nuts are on the end of longish bolts that go through the suspension upright they are fitted to. To undo them you may have to have a spanner on the bolt tops, or they might be sufficiently jammed. The STUDS are for placing into two of the other spring pan fixings holes in the wishbone, ONCE THE PAN IS OFF AND IS TO BE REFITTED. The studs ensure the pan, when being refitted with the tool, goes up into the right place to get the securing bolts back in. I always put one stud in one of the innermost holes and one on a middle hole.

Last edited by Greg in France; 02-18-2022 at 05:12 AM.

The following 4 users liked this post by Greg in France:

#4

Anderson--Greg has it correct. As to the mystery part of the tool please remember that Churchill tools are composite tools. If you will note you ordered the "G" version of the tool. That tool in its first version was a J6. By the early 60s it was at the 'B' version. Over the years attachments (or parts) were added to allow its use on other models. With the "G' version you do rec. an additional adaptor which is not needed for the XJ-S. That said we issue the tools complete. You are correct in following the WSM which you agreed to do when you loaned the tool. Your other question was to the locator pins. They are not needed in removal other than sometimes the pan will rotate and they eliminate that situation. As far as your question about the bronze wedge you have it correct if the vid is viewed correctly. There is a reason the wedge is a soft metal and if you look closely you will see it is rounded on the edge. The necessity of this is to allow the tool to swing as the spring compresses----it is not a straight line event--if it was the tool would be a lot simpler but it does highlight the folly of some home made tools. They not only have to fight the stress of compressing the spring but the lateral forces of a changing angle of attack. All that aside if you have further questions you should call the JCNA tech line and they will help you. 888-258-2524 (ex tech help).

#5

Anderson--Greg has it correct. As to the mystery part of the tool please remember that Churchill tools are composite tools. If you will note you ordered the "G" version of the tool. That tool in its first version was a J6. By the early 60s it was at the 'B' version. Over the years attachments (or parts) were added to allow its use on other models. With the "G' version you do rec. an additional adaptor which is not needed for the XJ-S. That said we issue the tools complete. You are correct in following the WSM which you agreed to do when you loaned the tool. Your other question was to the locator pins. They are not needed in removal other than sometimes the pan will rotate and they eliminate that situation. As far as your question about the bronze wedge you have it correct if the vid is viewed correctly. There is a reason the wedge is a soft metal and if you look closely you will see it is rounded on the edge. The necessity of this is to allow the tool to swing as the spring compresses----it is not a straight line event--if it was the tool would be a lot simpler but it does highlight the folly of some home made tools. They not only have to fight the stress of compressing the spring but the lateral forces of a changing angle of attack. All that aside if you have further questions you should call the JCNA tech line and they will help you. 888-258-2524 (ex tech help).

#6

Starting at the top of the tool.

The bottom: The piece that you have in place against the spring pan is not orientated correctly. If you look carefully at one side of it you will see two machined out parts; these are to allow that piece to sit over the two short studs and nuts that hold the lower bump stop to the spring pan. Once they are correctly over it, that part will sit flat against the spring pan. It is deliberately wedge shaped to ensure, once it is in place properly, that the central tightening rod is pulling straight against the spring top. Without the wedge, the angle of pull would be off, as the bottom of the spring in the spring pan is NOT parallel with the spring top once the suspension is no longer compressed by the weight of the car.

The bottom: The piece that you have in place against the spring pan is not orientated correctly. If you look carefully at one side of it you will see two machined out parts; these are to allow that piece to sit over the two short studs and nuts that hold the lower bump stop to the spring pan. Once they are correctly over it, that part will sit flat against the spring pan. It is deliberately wedge shaped to ensure, once it is in place properly, that the central tightening rod is pulling straight against the spring top. Without the wedge, the angle of pull would be off, as the bottom of the spring in the spring pan is NOT parallel with the spring top once the suspension is no longer compressed by the weight of the car.

Then a couple sentences later you said "It is deliberately wedge shaped to ensure..." I thought #2 concerned the large slanted piece, but you said "wedge shaped", so now I'm picturing the wedge thing. Which one are you talking about here?

Last edited by MrAndersonGCC; 02-18-2022 at 09:06 AM.

#7

I am talking about the piece that very briefly appears in your video at about 30 secs in. The two indentations are onscreen for about a second only. This is also the piece that I mean by being wedge shaped in profile.

If you are still confused, post a still photo of each piece, and each side of each piece and I will explain again and try to be clearer.

If you look UNDER the spring pan you will see the two studs and nuts which hold the rubber pad you will see on the spring side of the pan. This is a bump stop and it prevents the spring cracking against itself on full bump (ie full suspension upwards travel).

If you are still confused, post a still photo of each piece, and each side of each piece and I will explain again and try to be clearer.

If you look UNDER the spring pan you will see the two studs and nuts which hold the rubber pad you will see on the spring side of the pan. This is a bump stop and it prevents the spring cracking against itself on full bump (ie full suspension upwards travel).

Last edited by Greg in France; 02-18-2022 at 09:43 AM.

Trending Topics

#8

Ok, that makes sense. I think I found the two studs you're talking about in a photo I found online - I guess I just didn't notice them last night.

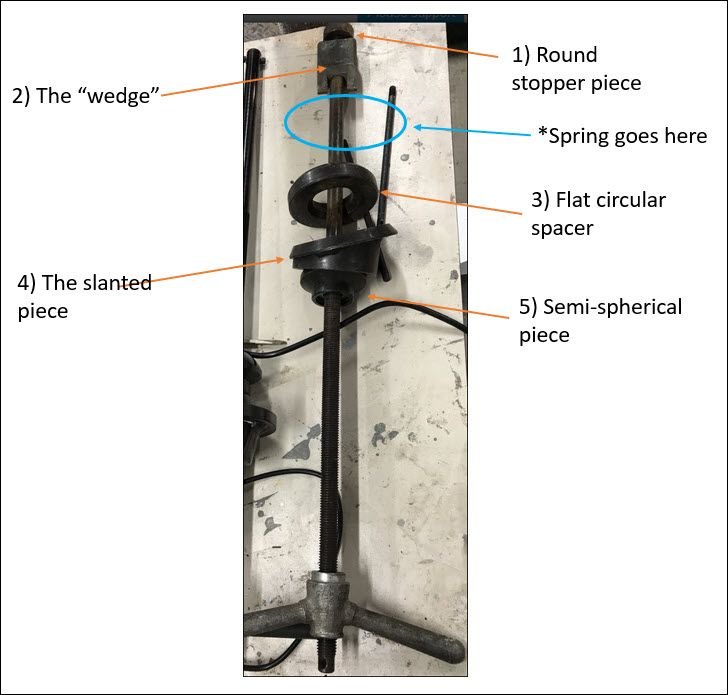

So from top to bottom, we have:

1) The round "stopper" piece that effectively locks into the rod

2) The wedge, which it seems I have oriented correctly in my video (it should run in line with the car, not perpendicular to it)

*The above two items are pushing down, or bracing against, the steel above the spring

3) The spring itself

4) The the lower spring pan

5) The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?

6) The slanted piece

7) The semi-spherical piece

8) The handle

Thanks for your patience, Greg.

So from top to bottom, we have:

1) The round "stopper" piece that effectively locks into the rod

2) The wedge, which it seems I have oriented correctly in my video (it should run in line with the car, not perpendicular to it)

*The above two items are pushing down, or bracing against, the steel above the spring

3) The spring itself

4) The the lower spring pan

5) The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?

6) The slanted piece

7) The semi-spherical piece

8) The handle

Thanks for your patience, Greg.

#9

#10

Ok, that makes sense. I think I found the two studs you're talking about in a photo I found online - I guess I just didn't notice them last night.

So from top to bottom, we have:

1) The round "stopper" piece that effectively locks into the rod

2) The wedge, which it seems I have oriented correctly in my video (it should run in line with the car, not perpendicular to it)

*The above two items are pushing down, or bracing against, the steel above the spring

3) The spring itself

4) The the lower spring pan

5) The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?

6) The slanted piece

7) The semi-spherical piece

8) The handle

Thanks for your patience, Greg.

So from top to bottom, we have:

1) The round "stopper" piece that effectively locks into the rod

2) The wedge, which it seems I have oriented correctly in my video (it should run in line with the car, not perpendicular to it)

*The above two items are pushing down, or bracing against, the steel above the spring

3) The spring itself

4) The the lower spring pan

5) The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?

6) The slanted piece

7) The semi-spherical piece

8) The handle

Thanks for your patience, Greg.

Do you mean by the wedge, the slotted locking piece?

What do you mean by this sentence: "The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?"

The part next to the spring pan HAS to be the bit with the stud indentations.

What do you mean by your numbers 6 and 7

Post a photo of them all laid out please.

#11

Some of this sounds wrong. Post a photo of the order you think it is and we will put you right.

Do you mean by the wedge, the slotted locking piece?

What do you mean by this sentence: "The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?"

The part next to the spring pan HAS to be the bit with the stud indentations.

What do you mean by your numbers 6 and 7

Post a photo of them all laid out please.

Do you mean by the wedge, the slotted locking piece?

What do you mean by this sentence: "The flat, circular spacer, which makes direct contact with the underside of the spring pan - though I don't think it has the indentations for the studs that the slanted piece has, so perhaps this goes in between the big slanted piece and the spherical piece?"

The part next to the spring pan HAS to be the bit with the stud indentations.

What do you mean by your numbers 6 and 7

Post a photo of them all laid out please.

#12

Using your terminology:

You do not need the wedge, the locking piece (which you call a "stopper" for some reason) goes directly on the top of the spring tower

You do not need the circular spacer. If you do use it (my JEC tool does not have it) then the forked end of it goes in line with the length of the car, so it can rock in and outwards as the angle changes. The round side of the locking piece, which must be downwards, has the same effect

The slanted piece goes against the spring pan and the indents in it fit the bump stop nuts.

The semi spherical piece comes last.

If you run out of thread when tightening the tool you need to insert a spacer under the semi spherical piece above the tightening handle. A stack of thick washers will do it, for example.

You do not need the wedge, the locking piece (which you call a "stopper" for some reason) goes directly on the top of the spring tower

You do not need the circular spacer. If you do use it (my JEC tool does not have it) then the forked end of it goes in line with the length of the car, so it can rock in and outwards as the angle changes. The round side of the locking piece, which must be downwards, has the same effect

The slanted piece goes against the spring pan and the indents in it fit the bump stop nuts.

The semi spherical piece comes last.

If you run out of thread when tightening the tool you need to insert a spacer under the semi spherical piece above the tightening handle. A stack of thick washers will do it, for example.

Last edited by Greg in France; 02-18-2022 at 11:34 AM.

#13

#15

Using your terminology:

You do not need the wedge, the locking piece (which you call a "stopper" for some reason) goes directly on the top of the spring tower

You do not need the circular spacer

The slanted piece goes against the spring pan and the indents in it fit the bump stop nuts

The semi spherical piece comes last

In your video I am sure I saw a thick tubular spacer, this may be needed if you run out of thread when tightening the tool. This spacer goes under the semi spherical piece above the tightening handle.

You do not need the wedge, the locking piece (which you call a "stopper" for some reason) goes directly on the top of the spring tower

You do not need the circular spacer

The slanted piece goes against the spring pan and the indents in it fit the bump stop nuts

The semi spherical piece comes last

In your video I am sure I saw a thick tubular spacer, this may be needed if you run out of thread when tightening the tool. This spacer goes under the semi spherical piece above the tightening handle.

#16

If the photo I posted is correct, then mine is not upside-down. I have it flat-side down, slant side up, with the slant facing the outside of the car to match the eventual outward bowing of the spring upon decompression.

#17

#18

Now I'm confused regarding the small wedge piece - the Coventry Foundation said in post #4 that it goes under the circular locking piece up top (what I called the "stopper" since it stops the rod from being pulled through the spring) in order to allow the tool to "sway" with the spring as it decompresses & bows. But in your #12 post you said that piece isn't necessary. I assume I'm misinterpreting one or both posts.

#19

Now I'm confused regarding the small wedge piece - the Coventry Foundation said in post #4 that it goes under the circular locking piece up top (what I called the "stopper" since it stops the rod from being pulled through the spring) in order to allow the tool to "sway" with the spring as it decompresses & bows. But in your #12 post you said that piece isn't necessary. I assume I'm misinterpreting one or both posts.

#20

There was one white plastic shim on top, and one on the bottom. However, beneath the bottom plastic shim is what appears to be a steel shim. The plastic ones fell out without any effort, but this thing doesnít want to budge. Is this a permanent structure or should I hammer away (and maybe torch it)?

Was also wondering about the lower control arm bushings. The left side obviously just has a nut, so the right (or rear-facing) end is the bolt itself. Is it possible to remove that bolt without completely removing the inner tie rod?

Last edited by MrAndersonGCC; 02-18-2022 at 02:38 PM.