how do I bench test dash gauges with multi meter

#1

I have taken my gauge cluster out of my 86 XJS V-12 to repair my gauges that don`t work for one reason or another and a cleaning. How can I bench test these gauges themselves with a multimeter before reinstalling them to make sure they work as they should. Is there a schematic for the ribbon on the back of the gauges so I can test those circuits also. Thanks in advance

#2

I have taken my gauge cluster out of my 86 XJS V-12 to repair my gauges that don`t work for one reason or another and a cleaning. How can I bench test these gauges themselves with a multimeter before reinstalling them to make sure they work as they should. Is there a schematic for the ribbon on the back of the gauges so I can test those circuits also. Thanks in advance

For the gauges the way that current/information is delivered from the ribbon to the individual gauges is important and are fiddly. Basically there are screws and bolts, with tiny washers, that carry current/information driving the gauge. The screws and bolts make a pressure contact with the ribbon on the outside of the cluster, then the treads of the screws/bolts run into and on plates in the individual gauges delivering the signal. CAREFUL removal of the screws and bolts, cleaning of them and cleaning of the plates in the walls of the individual gauges will sometimes help.

If you are more technical and knowledgeable on electrics than I am (and most people here are) and start deriving values from the gauges you have and what they SHOULD be from another source I think that would be a great set of and contribution to the forum. It's very possible that it exists and is already in the forum, but I ain't never seent it, lol...

Right now I'm dealing with an speedometer (or 2) that doesn't work. At rest, car started, it's getting B+ voltage where it should (green wire from memory) 1.5v in P, wheels not spinning, at the 2nd of the 3 and a good ground at the 3rd pin on the back of the gauge.... and the speedometer doesn't work. I don't know WHAT the values in the wire that provides the information should be, I wish I did...

For me, one of the problems is fear. The ribbon is so fragile, quarters for accessing the back of the panel when connected are so tight that a FEAR of doing more harm than good - crating a short and or damaging the panel - prevent me from doing anything like trying to take measurements while the thing is installed.

Anywho.

#4

Thanks JayJagJay, I can certainly use the schematic to some extent. I know what you mean about the ribbon being fragile and I would definetly recommend anyone doing this to study the ribbon and screws and to take your time, watch the ribbon while you loosen the screws to make sure the ribbon doesn`t twist under the screw and have a few different screwdrivers handy, if one doesn`t fit tightly in the screw head try another and another and another until hopefully you`ll find one that fits tight, and don`t strip the head out or there could be more trouble removing it. If the ribbon starts to move with the screw, tighten and loosen working them until you can get them moving without bringing the ribbon with it Mine were rusted and though they screw into plastic some of them were a real bear to get out. I managed to save the ribbon in my parts cluster because I screwed up the original not following my own advice and even broke some of the plastic where the screws screw into. From my parts cluster I`m using the plastic shell because that one is good and the ribbon which I managed to remove without damage because I screwed the old one up. I can`t even move the needles on my parts gauges but my originals at least move so I`m hoping they test okay. I will just see if they work, though I don`t know how accurate they will be, at least they are freed up. I`m assuming that the ribbon I screwed up is the reason for them not working. I`ll post how I make out. Thanks for the info. Rod

#5

Thanks JayJagJay, I can certainly use the schematic to some extent. I know what you mean about the ribbon being fragile and I would definetly recommend anyone doing this to study the ribbon and screws and to take your time, watch the ribbon while you loosen the screws to make sure the ribbon doesn`t twist under the screw and have a few different screwdrivers handy, if one doesn`t fit tightly in the screw head try another and another and another until hopefully you`ll find one that fits tight, and don`t strip the head out or there could be more trouble removing it. If the ribbon starts to move with the screw, tighten and loosen working them until you can get them moving without bringing the ribbon with it Mine were rusted and though they screw into plastic some of them were a real bear to get out. I managed to save the ribbon in my parts cluster because I screwed up the original not following my own advice and even broke some of the plastic where the screws screw into. From my parts cluster I`m using the plastic shell because that one is good and the ribbon which I managed to remove without damage because I screwed the old one up. I can`t even move the needles on my parts gauges but my originals at least move so I`m hoping they test okay. I will just see if they work, though I don`t know how accurate they will be, at least they are freed up. I`m assuming that the ribbon I screwed up is the reason for them not working. I`ll post how I make out. Thanks for the info. Rod

__________________

__________________

#6

If it were me, I'd do a simple continuity test at both ends of the ribbon, and then test the gauges directly, since all of the posts will be easy to get to.

I assume you have the electrical drawings for your car? JagRepair.com - Jaguar Repair Information Resource

That should help you figure out what is supposed to see what.

I assume you have the electrical drawings for your car? JagRepair.com - Jaguar Repair Information Resource

That should help you figure out what is supposed to see what.

#7

Thanks JayJagJay, I can certainly use the schematic to some extent. I know what you mean about the ribbon being fragile and I would definetly recommend anyone doing this to study the ribbon and screws and to take your time, watch the ribbon while you loosen the screws to make sure the ribbon doesn`t twist under the screw and have a few different screwdrivers handy, if one doesn`t fit tightly in the screw head try another and another and another until hopefully you`ll find one that fits tight, and don`t strip the head out or there could be more trouble removing it. If the ribbon starts to move with the screw, tighten and loosen working them until you can get them moving without bringing the ribbon with it Mine were rusted and though they screw into plastic some of them were a real bear to get out. I managed to save the ribbon in my parts cluster because I screwed up the original not following my own advice and even broke some of the plastic where the screws screw into. From my parts cluster I`m using the plastic shell because that one is good and the ribbon which I managed to remove without damage because I screwed the old one up. I can`t even move the needles on my parts gauges but my originals at least move so I`m hoping they test okay. I will just see if they work, though I don`t know how accurate they will be, at least they are freed up. I`m assuming that the ribbon I screwed up is the reason for them not working. I`ll post how I make out. Thanks for the info. Rod

Trending Topics

#8

Checking the ribbons continuity is on my list. Mainly to see if I have gotten the ribbon ends clean enough to make a good connection. I scuffed them lightly with 220 grit sandpaper not wanting to go overboard but not so little as I have connection problems. The steel connectors on the bulbs raised havoc with the copper ribbon ends. I managed to clean them without ruining any , so far. Thanks for the advice.

#9

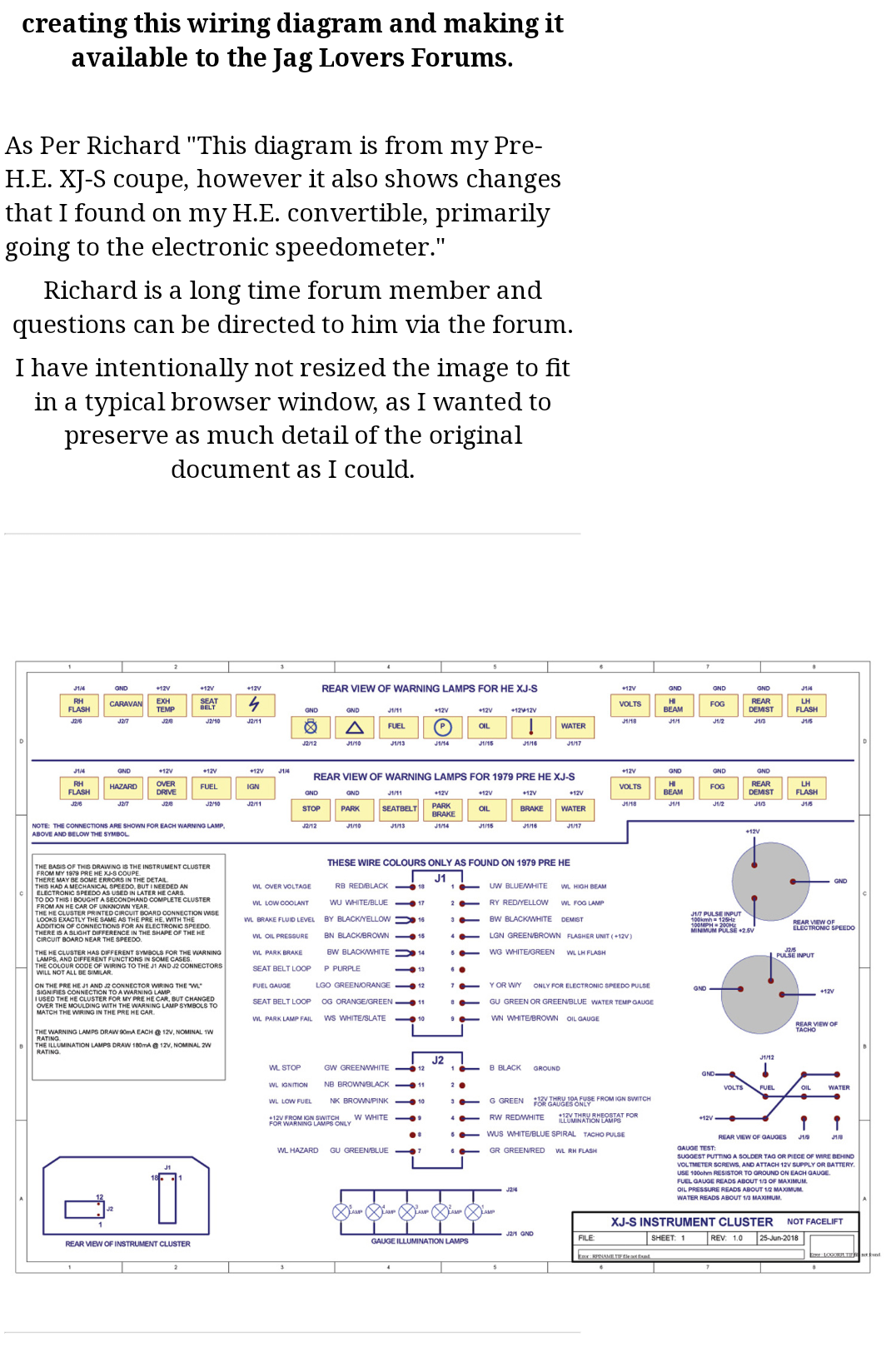

I made the instument cluster diagram shown in this post many years ago when overhauling the cluster in my pre HE coupe.

I also pulled the cluster out of my 88 convertible at the same time and noted the electtronic speedo mod.

Part of the reason was to put LED turn indicators in both clusters where I can actually see them.

As for the flexible printed circuit, they can be made cheaply in China. I know that becasue in my factory we get all our PCBs madei in China.

Top quality, 7-10 day turnaround incluuding UPS down to Oz. My guess is US$15 each landed here if I order about 20.

I don't have time to mess around and make the artwork. Anybody does that and sends me an Altium copy or Gerber filkes I can get a price

I could check if China can plate the connectors with gold too, unlike the bare copper ones in the OEM version.

I also pulled the cluster out of my 88 convertible at the same time and noted the electtronic speedo mod.

Part of the reason was to put LED turn indicators in both clusters where I can actually see them.

As for the flexible printed circuit, they can be made cheaply in China. I know that becasue in my factory we get all our PCBs madei in China.

Top quality, 7-10 day turnaround incluuding UPS down to Oz. My guess is US$15 each landed here if I order about 20.

I don't have time to mess around and make the artwork. Anybody does that and sends me an Altium copy or Gerber filkes I can get a price

I could check if China can plate the connectors with gold too, unlike the bare copper ones in the OEM version.

#10

I made the instument cluster diagram shown in this post many years ago when overhauling the cluster in my pre HE coupe.

I also pulled the cluster out of my 88 convertible at the same time and noted the electtronic speedo mod.

Part of the reason was to put LED turn indicators in both clusters where I can actually see them.

As for the flexible printed circuit, they can be made cheaply in China. I know that becasue in my factory we get all our PCBs madei in China.

Top quality, 7-10 day turnaround incluuding UPS down to Oz. My guess is US$15 each landed here if I order about 20.

I don't have time to mess around and make the artwork. Anybody does that and sends me an Altium copy or Gerber filkes I can get a price

I could check if China can plate the connectors with gold too, unlike the bare copper ones in the OEM version.

I also pulled the cluster out of my 88 convertible at the same time and noted the electtronic speedo mod.

Part of the reason was to put LED turn indicators in both clusters where I can actually see them.

As for the flexible printed circuit, they can be made cheaply in China. I know that becasue in my factory we get all our PCBs madei in China.

Top quality, 7-10 day turnaround incluuding UPS down to Oz. My guess is US$15 each landed here if I order about 20.

I don't have time to mess around and make the artwork. Anybody does that and sends me an Altium copy or Gerber filkes I can get a price

I could check if China can plate the connectors with gold too, unlike the bare copper ones in the OEM version.

So, what would one have to do to start this process... Would our ribbons need to be sent to china for the copying?

Would you be willing to start an individual thread offering the possibility of a new ribbon/circuit board?

#13

Richard I would be interested in the new circuit board also. I have it cleaned up and installed and it looks as though it will work with key on but I`m still waiting for the parts to get my XJS V-12 running so I can`t test all connections yet. I`ll be watching for further information. What do you mean by the artwork. The colored paths.

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)