so has anyone actually made 500bhp from a v12 pre.he

#741

If you used Chev small journal rods you could offset grind the 6.0L crank to 84mm. I didn't do this purely for cost reasons. Not sure where you are.....

There is a company in Newcastle that can hone the liners out of the block and grind the crank.

I got a quote for offset grinding from a company in Geelong at $3000, including balancing and nitride hardening.

The KB153 is the same as the KB143 except for the pin height 153 is 1.261 and 143 is 1.561.

I used the 143 and machined 0.040" off the top, benefit is lighter piston, shallower top ring land and 0.040" squish.

I also needed to machine 10cc out of the piston to get CR down to 10.5:1

There is a company in Newcastle that can hone the liners out of the block and grind the crank.

I got a quote for offset grinding from a company in Geelong at $3000, including balancing and nitride hardening.

The KB153 is the same as the KB143 except for the pin height 153 is 1.261 and 143 is 1.561.

I used the 143 and machined 0.040" off the top, benefit is lighter piston, shallower top ring land and 0.040" squish.

I also needed to machine 10cc out of the piston to get CR down to 10.5:1

The following users liked this post:

ronbros (03-15-2017)

#742

Mike,

You should build the 6.0, and ship the Pre HE to me

Seriously though, How do you guys figure out what the CR will be, as well as which pistons & rods you need to buy, and what mods you need to make to them, and/or, to the heads in order to achieve it? Is there a formula, or, a readily available program to do this?

You should build the 6.0, and ship the Pre HE to me

Seriously though, How do you guys figure out what the CR will be, as well as which pistons & rods you need to buy, and what mods you need to make to them, and/or, to the heads in order to achieve it? Is there a formula, or, a readily available program to do this?

#743

Ron:

On 84 mm cranks: there was a guy on the Jag Lovers list who offset ground a 6L crank (the later cast version that Ford switched to), and ended up cutting into an oil galley, ruining the crank. Now I do not know if they made a mistake on grinding, or if this was a problem with the cast 6L crank, or could be a problem with the forged 6L crank, but I did not want to kick that dog. That, and now I am looking at a lot more work, choosing con rods, bearing, and then fussy machine work and fitment. I think I can get to where I want to be going more the assembly route, with some minor machine work to touch up things here and there.

I have two shops that I have worked with in the past, and they are quite competent, just costly. And their main experience (the one shop, anyway) is on V8's, and the V12 throws them for a moment or two each time I come in (I can literally see the dollar signs spinning behind their eyeballs as we discuss details). But they know what they are doing and do good work. The other shop knows this engine inside and out, and yes, they are costly, too. So, I am trying to keep the risks and costs manageable!

Someone, somewhere will do that remote-mounted turbo setup you have been championing, and when they do, you and I (and a bunch of others) will cheer them on! It won't be me doing that project, though, unfortunately!

On 84 mm cranks: there was a guy on the Jag Lovers list who offset ground a 6L crank (the later cast version that Ford switched to), and ended up cutting into an oil galley, ruining the crank. Now I do not know if they made a mistake on grinding, or if this was a problem with the cast 6L crank, or could be a problem with the forged 6L crank, but I did not want to kick that dog. That, and now I am looking at a lot more work, choosing con rods, bearing, and then fussy machine work and fitment. I think I can get to where I want to be going more the assembly route, with some minor machine work to touch up things here and there.

I have two shops that I have worked with in the past, and they are quite competent, just costly. And their main experience (the one shop, anyway) is on V8's, and the V12 throws them for a moment or two each time I come in (I can literally see the dollar signs spinning behind their eyeballs as we discuss details). But they know what they are doing and do good work. The other shop knows this engine inside and out, and yes, they are costly, too. So, I am trying to keep the risks and costs manageable!

Someone, somewhere will do that remote-mounted turbo setup you have been championing, and when they do, you and I (and a bunch of others) will cheer them on! It won't be me doing that project, though, unfortunately!

The following users liked this post:

ronbros (03-16-2017)

#744

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

got it mike, i do understand.

you gotta do what you think is best!

i was kinda thinkin a big cubic engine or a smaller remote twin turb.

change of subject:

if i had good low mile stock, US HE version,(most common) i would love to try the remote turbo setup ,with a custom ECU, and the water/ Alky setup to control detonation , No one has ever even thought about such a mod for a Jag V12!

ron

you gotta do what you think is best!

i was kinda thinkin a big cubic engine or a smaller remote twin turb.

change of subject:

if i had good low mile stock, US HE version,(most common) i would love to try the remote turbo setup ,with a custom ECU, and the water/ Alky setup to control detonation , No one has ever even thought about such a mod for a Jag V12!

ron

#745

The following 3 users liked this post by xjr5006:

#747

Better than no problems, raises the liners so the bottom dosen't need machining.

Real hard top spec ali

The late great Ron Beaty use this method over 30 to 40 years ago

Had Lister engines with liner spacers, think they sometimes machined the top grooves off cooper ring liners which left them a tad short

Real hard top spec ali

The late great Ron Beaty use this method over 30 to 40 years ago

Had Lister engines with liner spacers, think they sometimes machined the top grooves off cooper ring liners which left them a tad short

The following users liked this post:

Greg in France (03-17-2017)

#748

OK xjr5006, I'll bite.

You are right, there's no such thing as a budget on doing these motors. Who are we kidding? There's big piles of money and then REALLY big piles of money. I hold no illusions. I just don't want to end up in the REALLY big piles of money camp.

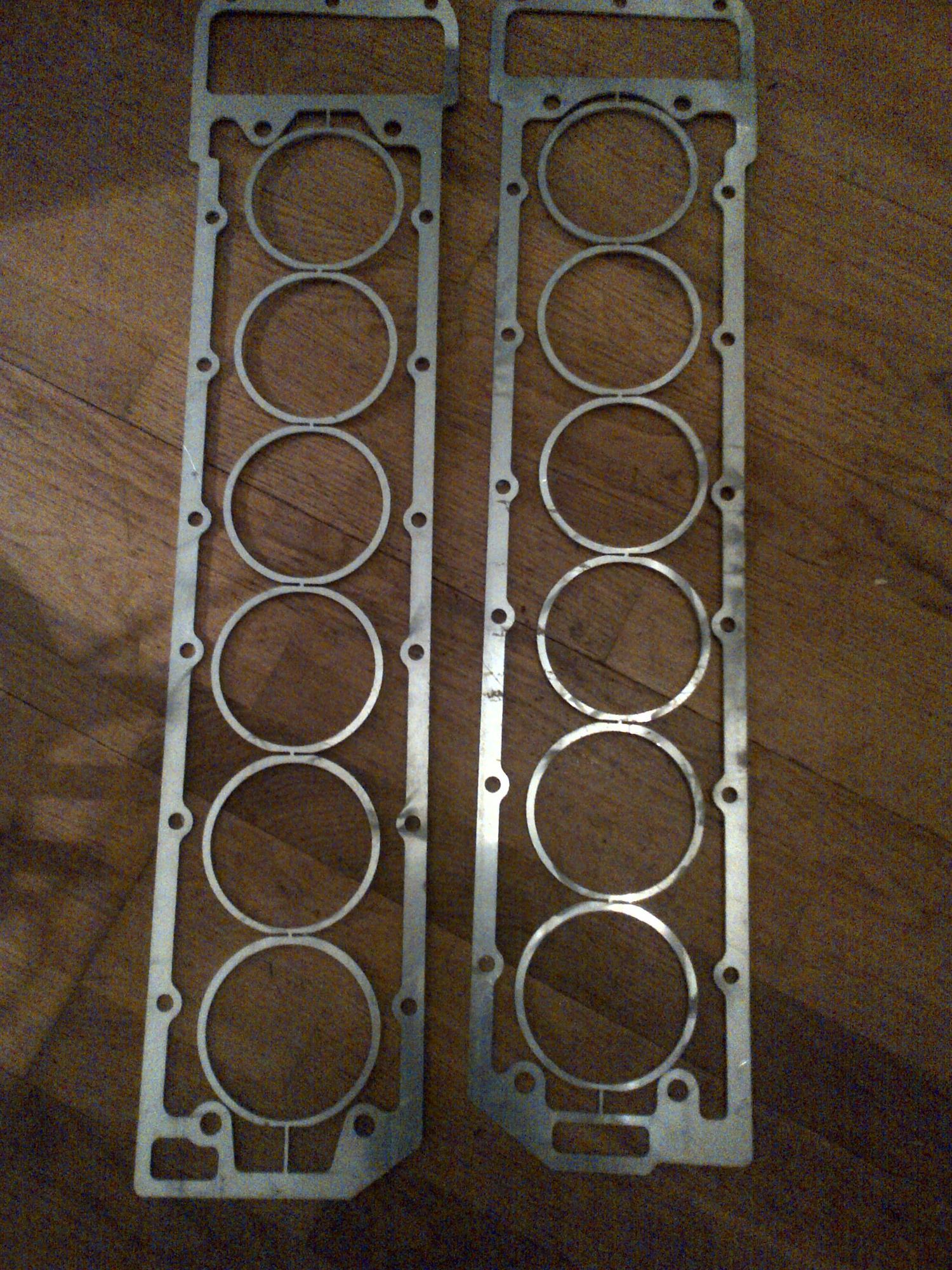

So, recognizing this, what I am I to understand about this photo: that this is a head spacer plate with sleeve spacers that are detached and cleaned up, and then are placed at the bottom of the block where the OEM liners usually sit, and the OEM liners are then sitting on these rings? I guess the only thing needed then would be a link or so in the timing chain, and you're off to the races?

I like it, so far. The question is, can one get 84 mm cranks that sport the OEM lip seal, so that they can be used in the later blocks, or are we stuck dealing with the rope seal?

-M

You are right, there's no such thing as a budget on doing these motors. Who are we kidding? There's big piles of money and then REALLY big piles of money. I hold no illusions. I just don't want to end up in the REALLY big piles of money camp.

So, recognizing this, what I am I to understand about this photo: that this is a head spacer plate with sleeve spacers that are detached and cleaned up, and then are placed at the bottom of the block where the OEM liners usually sit, and the OEM liners are then sitting on these rings? I guess the only thing needed then would be a link or so in the timing chain, and you're off to the races?

I like it, so far. The question is, can one get 84 mm cranks that sport the OEM lip seal, so that they can be used in the later blocks, or are we stuck dealing with the rope seal?

-M

#749

OK xjr5006, I'll bite.

You are right, there's no such thing as a budget on doing these motors. Who are we kidding? There's big piles of money and then REALLY big piles of money. I hold no illusions. I just don't want to end up in the REALLY big piles of money camp.

So, recognizing this, what I am I to understand about this photo: that this is a head spacer plate with sleeve spacers that are detached and cleaned up, and then are placed at the bottom of the block where the OEM liners usually sit, and the OEM liners are then sitting on these rings? I guess the only thing needed then would be a link or so in the timing chain, and you're off to the races?

I like it, so far. The question is, can one get 84 mm cranks that sport the OEM lip seal, so that they can be used in the later blocks, or are we stuck dealing with the rope seal?

-M

You are right, there's no such thing as a budget on doing these motors. Who are we kidding? There's big piles of money and then REALLY big piles of money. I hold no illusions. I just don't want to end up in the REALLY big piles of money camp.

So, recognizing this, what I am I to understand about this photo: that this is a head spacer plate with sleeve spacers that are detached and cleaned up, and then are placed at the bottom of the block where the OEM liners usually sit, and the OEM liners are then sitting on these rings? I guess the only thing needed then would be a link or so in the timing chain, and you're off to the races?

I like it, so far. The question is, can one get 84 mm cranks that sport the OEM lip seal, so that they can be used in the later blocks, or are we stuck dealing with the rope seal?

-M

#750

Jaguar never made an 84mm crank with road lip seal. Nor did TWR nor did Group 44. Lister had some made when they couldn't get hold of an ex TWR race crank,

The race version is 100mm at the lip, road is 114mm from memory, an ali spacer ring sorted that out.

So its a custom crank or a recut or welded 6L !

Never had a problem with the rope seals, it is always the owner or the builder that at fault!

Builders dont soak the seals in oil for long enough: if at all (I like 1 week then into a sealed bag for later use.)

Owners have engines or cars that have been sitting for years and are surprised when the seals dry out starting can then simply burn out the seal, no coming back after that.

Group 44 ended up grinding back to Chevy again and using a Chevy split lip seal.

My view is you stick to the setup you have be it lip or rope

At least you can get flywheels for the rope cranks !

The race version is 100mm at the lip, road is 114mm from memory, an ali spacer ring sorted that out.

So its a custom crank or a recut or welded 6L !

Never had a problem with the rope seals, it is always the owner or the builder that at fault!

Builders dont soak the seals in oil for long enough: if at all (I like 1 week then into a sealed bag for later use.)

Owners have engines or cars that have been sitting for years and are surprised when the seals dry out starting can then simply burn out the seal, no coming back after that.

Group 44 ended up grinding back to Chevy again and using a Chevy split lip seal.

My view is you stick to the setup you have be it lip or rope

At least you can get flywheels for the rope cranks !

Last edited by xjr5006; 03-17-2017 at 03:55 PM.

#751

#752

Yes, plan well ahead and after a week or more put into a bag with a seal for use later.

The following 4 users liked this post by xjr5006:

#753

Well after a loooong time away from this forum, I somehow got the urge to google Jaguar v12's again and this thread came up. Taken me the better part of 2 days to catch up on 38 pages of discussion!

About the OP's question. 500hp. In all honesty, aside from a few well educated posters in this topic, who can honestly say that they have strapped themselves into a 500hp Jag V12 powered beast, and lived to tell the tale?!?

For the average enthusiast ( myself included ) I can distinctly remember the smile on my face once I tossed out the turbo 400, and installed the 5 speed kit, and a set of extractors! Now I know for sure my engine has a few ponies that have escaped the stable, but the increase in driveability was tremendous. I was absolutely amazed. Now, having been impressed by that alone, I thought are we focusing to much on the 500hp? Knowing what a difference the manual box made, if the OP asked has anyone build a 450hp engine, or 400hp engine, I'm sure 90% of the replies would be more positive and the target would not seem like such a tall order.

What if i asked, has anyone build a Pre HE engine that FEELS like it has 500hp? Asking because I fell into that mindset of chasing a mythical number. Now, a little wiser, and a lot greyer, I am looking to build my V12, but I wont cry if it falls short of a number on a dyno sheet. I know I wont keep up with my friends with the 500hp Torana, or the 550hp SBC Kingswood. BUT! I will have a V12. They wont. I will have a gentlemans engine, with the proper amount of cylinders. They wont. This mindset obviously entails some compromise though!

So, about 5 years ago, I did spend a boatload of cash on some go fast bits, I got the 84mm forged crank, (EAC2757-84EXP, Rope seal) Hi capacity oil pump, and 96mm liners, and a set of carrillo rods to suit.

Now I was all set on getting a batch of pistons made, 96mm, but after sifting through this post, would it be better to stay with 90-90.5mm? The thinking being bringing the motor closer to square is better than a 96mm bore, 84 stroke combo. If anyone can settle that definatively for me that would be great.

And yes, the good book by Allan Scott is on order.

This may be heretical, but I love the idea of 12ITB. Especially the Jenvey crossflow setup. I have spent many hours wondering if that would make the car better, or make me feel better about the car. Surely there is some formula out there that can quantify that !!

If any of the Australian members could point me in the right direction of knowledgable cylinder head builders, and some piston help as well I'd me very grateful.

Also, I have 1 spare raw forging for an 84mm crank, and access to another. When I got my crank from Rob Beere Racing, I figured they might come in handy. If anyone is interested, especially if they can help with Heads, that would be great too.

Sorry to ramble, I have thoroughly enjoyed reading this entire post. It has re-ignited the passion somewhat to get my ar** back into gear and move forward.

Thanks to everyone that has contributed to this post. I may not have asked the original question, but I sure have gained a lot of knowledge anyway.

Cheers

Chris

About the OP's question. 500hp. In all honesty, aside from a few well educated posters in this topic, who can honestly say that they have strapped themselves into a 500hp Jag V12 powered beast, and lived to tell the tale?!?

For the average enthusiast ( myself included ) I can distinctly remember the smile on my face once I tossed out the turbo 400, and installed the 5 speed kit, and a set of extractors! Now I know for sure my engine has a few ponies that have escaped the stable, but the increase in driveability was tremendous. I was absolutely amazed. Now, having been impressed by that alone, I thought are we focusing to much on the 500hp? Knowing what a difference the manual box made, if the OP asked has anyone build a 450hp engine, or 400hp engine, I'm sure 90% of the replies would be more positive and the target would not seem like such a tall order.

What if i asked, has anyone build a Pre HE engine that FEELS like it has 500hp? Asking because I fell into that mindset of chasing a mythical number. Now, a little wiser, and a lot greyer, I am looking to build my V12, but I wont cry if it falls short of a number on a dyno sheet. I know I wont keep up with my friends with the 500hp Torana, or the 550hp SBC Kingswood. BUT! I will have a V12. They wont. I will have a gentlemans engine, with the proper amount of cylinders. They wont. This mindset obviously entails some compromise though!

So, about 5 years ago, I did spend a boatload of cash on some go fast bits, I got the 84mm forged crank, (EAC2757-84EXP, Rope seal) Hi capacity oil pump, and 96mm liners, and a set of carrillo rods to suit.

Now I was all set on getting a batch of pistons made, 96mm, but after sifting through this post, would it be better to stay with 90-90.5mm? The thinking being bringing the motor closer to square is better than a 96mm bore, 84 stroke combo. If anyone can settle that definatively for me that would be great.

And yes, the good book by Allan Scott is on order.

This may be heretical, but I love the idea of 12ITB. Especially the Jenvey crossflow setup. I have spent many hours wondering if that would make the car better, or make me feel better about the car. Surely there is some formula out there that can quantify that !!

If any of the Australian members could point me in the right direction of knowledgable cylinder head builders, and some piston help as well I'd me very grateful.

Also, I have 1 spare raw forging for an 84mm crank, and access to another. When I got my crank from Rob Beere Racing, I figured they might come in handy. If anyone is interested, especially if they can help with Heads, that would be great too.

Sorry to ramble, I have thoroughly enjoyed reading this entire post. It has re-ignited the passion somewhat to get my ar** back into gear and move forward.

Thanks to everyone that has contributed to this post. I may not have asked the original question, but I sure have gained a lot of knowledge anyway.

Cheers

Chris

The following users liked this post:

Jonathan-W (04-20-2017)

#754

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

so many variables of questions!

but generly a respectable engine will make at least one HP per cubic inch of displacement! at the flywheel!

any more becomes a good performance/race engine.

todays technology has almost 1.5 hp per inch NA, with basic simple mods!

just about any great engines today are forced induction/supercharged ETC.

2,3, 4 hp per inch or more is becoming common place!

and one may buy the best products/parts and it then relates to the research and knowledge of assembly to make a reliable,powerful engine!

also look at making the most torque and leaving the final HP as a formula number!

on a street car torque will get you away quickest, and passing easier!

Ron

nothing against 12 ITB but it would be a nightmare to tune properly, looks very intimidating , but rarely better than a good plenum chamber/runner setup.

but generly a respectable engine will make at least one HP per cubic inch of displacement! at the flywheel!

any more becomes a good performance/race engine.

todays technology has almost 1.5 hp per inch NA, with basic simple mods!

just about any great engines today are forced induction/supercharged ETC.

2,3, 4 hp per inch or more is becoming common place!

and one may buy the best products/parts and it then relates to the research and knowledge of assembly to make a reliable,powerful engine!

also look at making the most torque and leaving the final HP as a formula number!

on a street car torque will get you away quickest, and passing easier!

Ron

nothing against 12 ITB but it would be a nightmare to tune properly, looks very intimidating , but rarely better than a good plenum chamber/runner setup.

Last edited by ronbros; 04-19-2017 at 05:19 PM.

The following 2 users liked this post by ronbros:

cat_as_trophy (04-20-2017),

xjsv12 (04-20-2017)

#755

Norman Lutz is building a 6.7L V12 for me ATM, based on a 6.0L 78.5mm crank and 95mm liners with Chev 305 pistons. He estimates torque should be in the vicinity of 450ft/lb's and with the right head mods hp should be around 450 at 6000rpm.

I have a head in my shed he loaned me to run on my flow bench, it's from a 6.0L V12 he built for a boat which made 615hp. That's great for a race engine but what matters most for road car is torque.

I agree with Ron my engine build will focus on torque and optimizing the heads and let HP be what it ends up.

I have a head in my shed he loaned me to run on my flow bench, it's from a 6.0L V12 he built for a boat which made 615hp. That's great for a race engine but what matters most for road car is torque.

I agree with Ron my engine build will focus on torque and optimizing the heads and let HP be what it ends up.

#756

Join Date: Nov 2013

Location: Inverell, NSW, Australia

Posts: 3,052

Received 1,442 Likes

on

898 Posts

- at 650BHP @ 7800RPM (limited), we were pushing the envelope at near 1.8hp per cubic inch . . . as you say, well shy of today's race craft;

- sponsorships budget warranted the R&D and production costs of these 4 engines (2 expiring on the dyno) which, IIRC, ran to a total of AU$50,000 in 1980s money . . . say, AU$150,000 today.

Cheers,

Ken

The following users liked this post:

ronbros (04-20-2017)

#757

Join Date: Nov 2013

Location: Inverell, NSW, Australia

Posts: 3,052

Received 1,442 Likes

on

898 Posts

Best wishes with your build, mate

Ken

#758

Hey Warren . . . your post came through as I was called away from composing mine. You're a very smart fella . . . and for what it's worth . . . torque is totally what it was all about in race craft back in my day; probably still is.

Best wishes with your build, mate

Ken

Best wishes with your build, mate

Ken

I also had VL turbo in the late 1980's with 450hp it was a pig to drive due to nil low down torque and light switch power delivery. It was great if you kept RPM over 4000.

The following 2 users liked this post by warrjon:

cat_as_trophy (04-20-2017),

ronbros (04-20-2017)

#759

Join Date: Nov 2013

Location: Inverell, NSW, Australia

Posts: 3,052

Received 1,442 Likes

on

898 Posts

Cheers,

Ken

The following users liked this post:

ronbros (04-20-2017)