so has anyone actually made 500bhp from a v12 pre.he

#981

What we need for the XJS enthusiast is a forced induction kit like they have for the Porsche 928 - several kits actually, and $5k + installation will reliably get you into the 450HP club! There's also Kuhn Performance twin turbo 928 kit which is on another level re: performance, aesthetics, and price. Looks like their website is down. Pity.

#982

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

Flint nice idea ,but a tuning nightmare, i have built many turbo engines and the tuning is most important!

when engine starts boost up , fuel AFR changes drasticly! inlet manifold pressure goes from a vacuum to a positive pressure, computors can go nuts!

and a slight mistake you may build a new motor!

where NA engines you can be off a mile and still have an something to work with!

BUT go for it and show what you got!

when engine starts boost up , fuel AFR changes drasticly! inlet manifold pressure goes from a vacuum to a positive pressure, computors can go nuts!

and a slight mistake you may build a new motor!

where NA engines you can be off a mile and still have an something to work with!

BUT go for it and show what you got!

The following 3 users liked this post by ronbros:

#983

Thanks. Are you using your own ECU on this engine? Have you built any large displacement performance V12?

ps great to see some new tech applied to the V12.

ps great to see some new tech applied to the V12.

Hi John

Yes I have a Batch of cnc ported heads going on, with new guides and oversized valves. Will be ready just over summer holiday I think.

And options like a special valvespring-retainer-lifter setup to be able to use cams with better profiles.

The heads will fit exixtig std parts, but my new cams require the special setup with different lifters and springs as I have made them with larger basediameter than the standard 29mm. This makes me able to make high lift low duration cams, or anything above that.

I also do cams with the std 29mm basediameter ofcorse, but then we need to go up on duration to make more lift. Some want that and it is ok to, but I want to have the possibility of std duration and 12.5mm lift.

Ole Mobeck

Yes I have a Batch of cnc ported heads going on, with new guides and oversized valves. Will be ready just over summer holiday I think.

And options like a special valvespring-retainer-lifter setup to be able to use cams with better profiles.

The heads will fit exixtig std parts, but my new cams require the special setup with different lifters and springs as I have made them with larger basediameter than the standard 29mm. This makes me able to make high lift low duration cams, or anything above that.

I also do cams with the std 29mm basediameter ofcorse, but then we need to go up on duration to make more lift. Some want that and it is ok to, but I want to have the possibility of std duration and 12.5mm lift.

Ole Mobeck

The following users liked this post:

CaptainShakey (06-28-2021)

#984

Flint nice idea ,but a tuning nightmare, i have built many turbo engines and the tuning is most important!

when engine starts boost up , fuel AFR changes drasticly! inlet manifold pressure goes from a vacuum to a positive pressure, computors can go nuts!

and a slight mistake you may build a new motor!

where NA engines you can be off a mile and still have an something to work with!

BUT go for it and show what you got!

when engine starts boost up , fuel AFR changes drasticly! inlet manifold pressure goes from a vacuum to a positive pressure, computors can go nuts!

and a slight mistake you may build a new motor!

where NA engines you can be off a mile and still have an something to work with!

BUT go for it and show what you got!

The following users liked this post:

ronbros (06-28-2021)

#985

I am building a 6.1 liter right now, but from a 5,3 and by big bore pistons. Not a original 6 liter. This one is like a research engine.

And a customer have ordered a Marine engine, but I have not desided on stroke yet. I ilke the 70 stroke and want to show that it can deliver both torque and rpm.

I need to see some money first, before I start.

I have some new cam designs ready for it. And I need to finish the cnc port HE head range also as there are not so many good Pre HE heads to find.

Ole M

#987

Motec on this one, but that is just because of the dyno operators preference, and the internals of my ecu is not my design anyway, I just made a box for it with relays and fuses built into the design so people dont need to do any electric work and have it all as a compackt unit. And since I made it look like a jaguar nobody is arguing about the brand anymore. Its a modern well known ecu in there ready for anything..

I am building a 6.1 liter right now, but from a 5,3 and by big bore pistons. Not a original 6 liter. This one is like a research engine.

And a customer have ordered a Marine engine, but I have not desided on stroke yet. I ilke the 70 stroke and want to show that it can deliver both torque and rpm.

I need to see some money first, before I start.

I have some new cam designs ready for it. And I need to finish the cnc port HE head range also as there are not so many good Pre HE heads to find.

Ole M

I am building a 6.1 liter right now, but from a 5,3 and by big bore pistons. Not a original 6 liter. This one is like a research engine.

And a customer have ordered a Marine engine, but I have not desided on stroke yet. I ilke the 70 stroke and want to show that it can deliver both torque and rpm.

I need to see some money first, before I start.

I have some new cam designs ready for it. And I need to finish the cnc port HE head range also as there are not so many good Pre HE heads to find.

Ole M

What octane fuel is this set for?

Good stuff BTW

#988

This race engine has injectors coupled in pairs and fire one a revolution in correct sequence, and I use one coil and distributor. This is because of FIA Historic regulations.

The Bolt on kit I make has two choises, one std witch use one coil and distributor, this one fire two and two injectors in batces. No cam signal as it is really bolt on, customer dont need to understand anything.

The other choise is waste spark, where you remove the distributor and run two six pack coils. Also here I pair the injectors. And completely bolt on. No special timing needed, unless someone want to make the map themselves.

Sequential injectors with 12 channels and cam sensor has no real HP increase, but you may be able to get the idle superduper smooth if you dont think the idle of the normal setup is not super smooth enough. Witch it is..

Sequentioal injectors dont make more hp, end of discussion :-)

And on my bolt on kit I run 95 octane

Ole M

Last edited by Mobeck Tekniske; 06-30-2021 at 09:21 AM.

#989

Iíve watched many people go down the endless modification of the ECU trying to basically reprogram the engine for more power. To my knowledge none have proven it with before and after dyno runs.

Plug and play is adequate for the vast majority of us. Thatís hard for me to say, Iím a racer. Iím always looking for more power.

Plug and play is adequate for the vast majority of us. Thatís hard for me to say, Iím a racer. Iím always looking for more power.

#990

Hi

This race engine has injectors coupled in pairs and fire one a revolution in correct sequence, and I use one coil and distributor. This is because of FIA Historic regulations.

The Bolt on kit I make has two choises, one std witch use one coil and distributor, this one fire two and two injectors in batces. No cam signal as it is really bolt on, customer dont need to understand anything.

The other choise is waste spark, where you remove the distributor and run two six pack coils. Also here I pair the injectors. And completely bolt on. No special timing needed, unless someone want to make the map themselves.

Sequential injectors with 12 channels and cam sensor has no real HP increase, but you may be able to get the idle superduper smooth if you dont think the idle of the normal setup is not super smooth enough. Witch it is..

Sequentioal injectors dont make more hp, end of discussion :-)

Ole M

This race engine has injectors coupled in pairs and fire one a revolution in correct sequence, and I use one coil and distributor. This is because of FIA Historic regulations.

The Bolt on kit I make has two choises, one std witch use one coil and distributor, this one fire two and two injectors in batces. No cam signal as it is really bolt on, customer dont need to understand anything.

The other choise is waste spark, where you remove the distributor and run two six pack coils. Also here I pair the injectors. And completely bolt on. No special timing needed, unless someone want to make the map themselves.

Sequential injectors with 12 channels and cam sensor has no real HP increase, but you may be able to get the idle superduper smooth if you dont think the idle of the normal setup is not super smooth enough. Witch it is..

Sequentioal injectors dont make more hp, end of discussion :-)

Ole M

I'm looking for better reliability, best possible performance without major engine mods and less finickiness. This is a good solution for that.

Last edited by Xjeffs; 06-30-2021 at 08:41 AM.

#991

Many think that the bigbore throttles and larger injectors will give them more power, that is not so.. but yes maybe a few hp but nothing you will write home about.

The gr.A engine was with std throttles and 209cc injectors at 4 bar. The thing that make power is an increase in Volumetric efficensy regarding the amount of air moved through the engine at two revolutions, and the injectors must just act accordingly to that.

Many also think an aftermarket ecu can be mapped in a couple of hours. well, yes a full trottle map and some transistions ca.

But I spent a month on the road afterwords driving and adjusting in the end.

Things like cold starts and transistions, slow driving, cruice control driving, slight downhill and not having the converter pulsing at cruice control, and fuel cut at all those situation, and avoiding hunting at idle at different temperatures and so on.

It is a lot of work to make a map that can be sold to anyone and that work perfect like that when actually driving slow like most do. That I something I would like people knew when considering time and cost of aftermarket ecu solutions...

Ole M

The gr.A engine was with std throttles and 209cc injectors at 4 bar. The thing that make power is an increase in Volumetric efficensy regarding the amount of air moved through the engine at two revolutions, and the injectors must just act accordingly to that.

Many also think an aftermarket ecu can be mapped in a couple of hours. well, yes a full trottle map and some transistions ca.

But I spent a month on the road afterwords driving and adjusting in the end.

Things like cold starts and transistions, slow driving, cruice control driving, slight downhill and not having the converter pulsing at cruice control, and fuel cut at all those situation, and avoiding hunting at idle at different temperatures and so on.

It is a lot of work to make a map that can be sold to anyone and that work perfect like that when actually driving slow like most do. That I something I would like people knew when considering time and cost of aftermarket ecu solutions...

Ole M

Last edited by Mobeck Tekniske; 06-30-2021 at 09:39 AM.

The following 5 users liked this post by Mobeck Tekniske:

Flint Ironstag (06-30-2021),

Mguar (06-30-2021),

Mike1610 (08-16-2021),

ronbros (06-30-2021),

Xjeffs (06-30-2021)

#992

Many think that the bigbore throttles and larger injectors will give them more power, that is not so.. but yes maybe a few hp but nothing you will write home about.

The gr.A engine was with std throttles and 209cc injectors at 4 bar. The thing that make power is an increase in Volumetric efficensy regarding the amount of air moved through the engine at two revolutions, and the injectors must just act accordingly to that.

Many also think an aftermarket ecu can be mapped in a couple of hours. well, yes a full trottle map and some transistions ca.

But I spent a month on the road afterwords driving and adjusting in the end.

Things like cold starts and transistions, slow driving, cruice control driving, slight downhill and not having the converter pulsing at cruice control, and fuel cut at all those situation, and avoiding hunting at idle at different temperatures and so on.

It is a lot of work to make a map that can be sold to anyone and that work perfect like that when actually driving slow like most do. That I something I would like people knew when considering time and cost of aftermarket ecu solutions...

Ole M

The gr.A engine was with std throttles and 209cc injectors at 4 bar. The thing that make power is an increase in Volumetric efficensy regarding the amount of air moved through the engine at two revolutions, and the injectors must just act accordingly to that.

Many also think an aftermarket ecu can be mapped in a couple of hours. well, yes a full trottle map and some transistions ca.

But I spent a month on the road afterwords driving and adjusting in the end.

Things like cold starts and transistions, slow driving, cruice control driving, slight downhill and not having the converter pulsing at cruice control, and fuel cut at all those situation, and avoiding hunting at idle at different temperatures and so on.

It is a lot of work to make a map that can be sold to anyone and that work perfect like that when actually driving slow like most do. That I something I would like people knew when considering time and cost of aftermarket ecu solutions...

Ole M

or fuel that carries air with it like alcohol does.

Then larger injectors might ( might) be required or just longer dwell time.

#993

Well said! A given engine will burn only so much fuel and air at a Given rpm. To change that requires either boost in the form of super/turbo charging

or fuel that carries air with it like alcohol does.

Then larger injectors might ( might) be required or just longer dwell time.

or fuel that carries air with it like alcohol does.

Then larger injectors might ( might) be required or just longer dwell time.

But to go passt 100% you must have a good plan and a good recipie, to get passt 110% you have full control of what you are doing. And 120% I have done only on 3 engines in my life. Some mention the helmholtz and plenums, well this is beyond that.

#994

What we need for the XJS enthusiast is a forced induction kit like they have for the Porsche 928 - several kits actually, and $5k + installation will reliably get you into the 450HP club! There's also Kuhn Performance twin turbo 928 kit which is on another level re: performance, aesthetics, and price. Looks like their website is down. Pity.

Ole M

#995

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

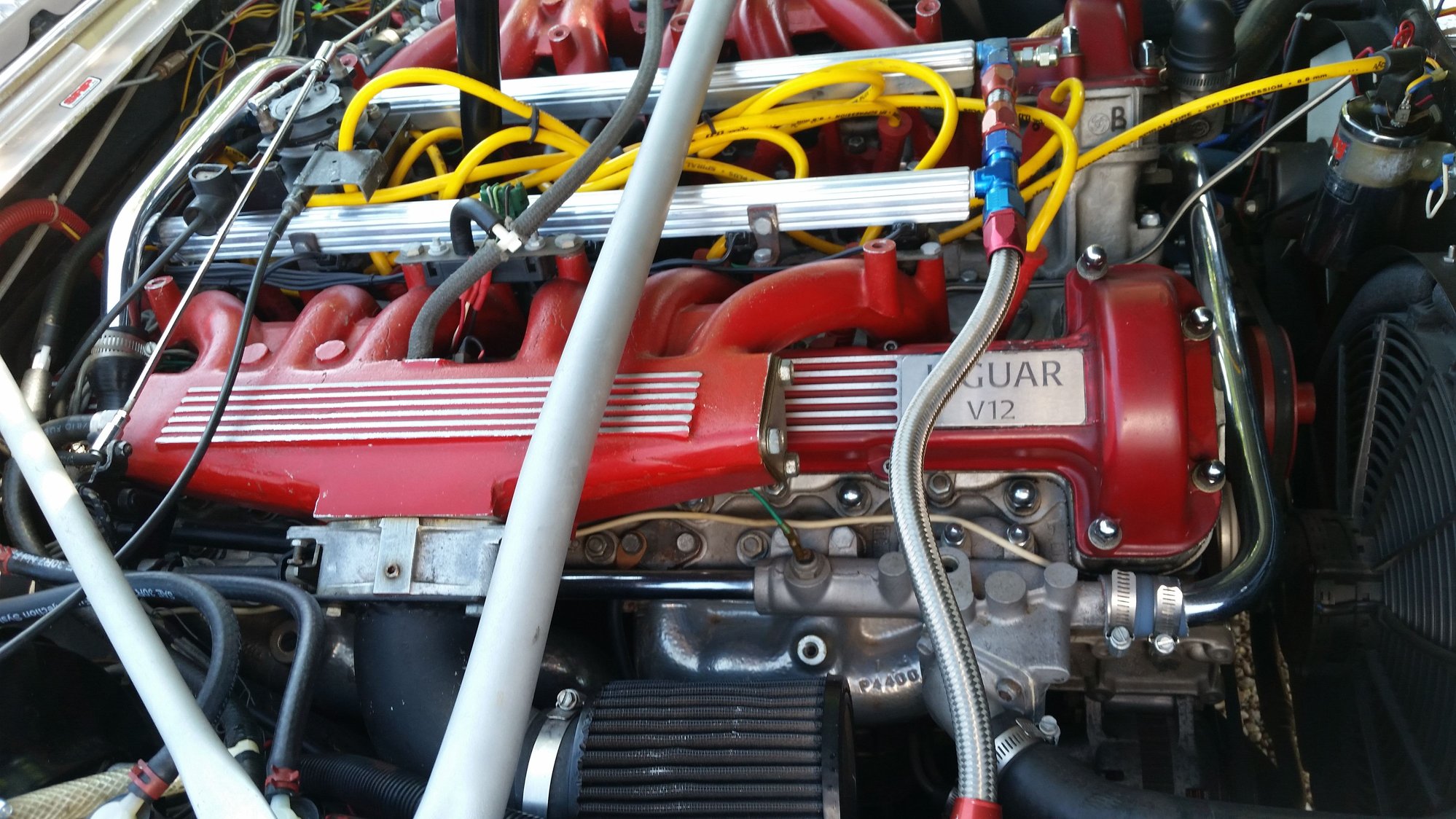

preHE inlet manifolds are EXTRUDE honed,takes out a lot of humps and bumps and a smooth runner entrance!

pic of my V12 with a a modded distributor, it uses a Crane ignition box, i adjust curve by altering weights(bothersome), but adjust total curve moving distributor! i also use a set of Crane custom grind cams, had a chance to run them on a cam profile machine(they are a copy of 1973 Porsche NA race engine profile) whooda thought?

for fuel i use a standalone SDS EFI sysytem, plenty of room for adjusting AFR using Gage! i use 12 HONDA injectors O-ring top and bottom, also 45psi adjustable! Plus a bunch of internal engine mods

YES old fashioned but works for me, rev easily over 6500 + rpm!

oh i spent the best part of a year getting a usable MAP, a learning process for sure!

and i still have minor readjust winter/summer!

Last edited by ronbros; 06-30-2021 at 04:25 PM.

#996

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

to add to above,, i do run 6MM oversize throttle bodies!

so when i open throttles the 1st 25% open lets much more air in and gets it moving faster , so throttle response is quicker!

probably wide open may not help much but lower opening is noticable, coming off a corner at slow speeds!

and with my lower gear rear drive(3.73 LSD), all is good!

ron

so when i open throttles the 1st 25% open lets much more air in and gets it moving faster , so throttle response is quicker!

probably wide open may not help much but lower opening is noticable, coming off a corner at slow speeds!

and with my lower gear rear drive(3.73 LSD), all is good!

ron

The following users liked this post:

Mguar (08-13-2021)

#997

to add to above,, i do run 6MM oversize throttle bodies!

so when i open throttles the 1st 25% open lets much more air in and gets it moving faster , so throttle response is quicker!

probably wide open may not help much but lower opening is noticable, coming off a corner at slow speeds!

and with my lower gear rear drive(3.73 LSD), all is good!

ron

so when i open throttles the 1st 25% open lets much more air in and gets it moving faster , so throttle response is quicker!

probably wide open may not help much but lower opening is noticable, coming off a corner at slow speeds!

and with my lower gear rear drive(3.73 LSD), all is good!

ron

#998

Yes I agree Ron. But there is something with the std setup that makes the throttles oper very slowly in the start, its about the geometry of the rods and links. It is possible and also smart to move the idle stop of the top disk quite a lot. Maybe 10mm to make the rods move faster in the start. Because if not the tps will go from 0 to 15 % without much happening at the throttle body, and a hot setup with a chrisp throttle response is difficoult to get with that original "over progressive" actuation. The original geometry is made for easy crucin with a sloppy auto trans I think.

#999

Last edited by Xjeffs; 07-02-2021 at 10:58 PM.

#1000

The problem is that the HE engine has too much compression for a bolt on Turbo/supercharger kit, and its the HE that most people have, So to make a boost kit for this one force you to open it and change pistons anyway, witch makes most people fall of. And that is a pity.

Ole M

Ole M

The few hundred left 40+ years later do not make a valid market.