V12 group44 heads project

#41

To typhoon.the pattern maker mentioned something to me the other day which i hadn't thought of prior. Metal shrinks when it cools. So to counteract that they make the pattern a bit larger than 100% . I dont know how much larger but when i pay for it i guess i will. Ive thought about this a lot as i want a second pair for my boat. And finally i have a responsibility to modern jaguar society.,that is not to mess up the last pair...

this is true...

any one that makes a pattern for casting has a set of special rulers...

these special rulers: one for each type of metal/alloy they cast...

normal practice it to take your design drawing and make them exactly to the dimensions you provided while using the special ruler that is for that metal they are casting...

(I found this out in my Large Scale Model Rail Road Hobby (they Like Live Steam)) and sometime casting there own Wheels and more complex bits...

so just give them the correct drawings.... now if they have gone computerized then still give them the correct drawings and they should just have to punch into their software which Alloy they are casting and it will scale it for shrinkage...

either way no worries if you got the right guys....

#44

I have a 1977 road&track magazine, with a complete wrightup*

on the Group44 XJS, lot of pix and a show of the rear*

suspension setup

hi ron any chance you could email me a copy of this article. Also what month was the article? Might see if i can get a copy...

on the Group44 XJS, lot of pix and a show of the rear*

suspension setup

hi ron any chance you could email me a copy of this article. Also what month was the article? Might see if i can get a copy...

#45

Yep you must be referring to one of my heads then, Off my XJR5. Dropped 4 valves at Le Mans when I grabbed a wrong gear whilst braking. Buzzed it maybe to 12 or even 14 and remember cringing as i put in the clutch too late Still finished on 10 cylinders though.

Not for sale, certainly not whilst I have and race XJR's,

£400 for repairs against unobtainable at any price is a no brainer. I should have gotten all the seats replaced with Beryllium at that time for the titanium valves I was having made but hey ho.

#46

HEY XJR5006, any chance finding any of these Tee shirts XL, bought this one around 1998 at Daytona/Rolex 24 hr track, when the cars were there for 24 race, bought at the TWR vendor tent $8. dollars(LOL).

anyway its showing signs of age, cant find any here in states!

pix of it.

anyway its showing signs of age, cant find any here in states!

pix of it.

Only usually keep the factory stuff

The following users liked this post:

ronbros (11-24-2015)

#47

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

mag was MAY 1977, road & track, Tullius article. so it would seem they built car in 1976-77.

seems i should put this magazine in a plastic holder, its getting yellow/brown flakey around the edges! YIKES its almost 40yrs old,comes to mind.

you cant believe how low prices were for Ferrari,Aston Martin cars, of the era.

you know how i can tell i been around cars a long time, my 1st car 1949(i was 15yrs old), 1934 FORD roadster V8 cost me $20. dollars, and just last week one sold at auction for $120,000. dollars.

if i had just the automobile magazines i have thrown in the dump, id be well off money wise!

#49

Hi ron, couldnt find the making 500hp site you are referring to. Did manage to find a copy of the magazine though. Its on its way from your great land... trying to get more technical info on the diff bracing that lister and group44 used. Have some photos but not enough info yet. Update on the heads. Will be going back to the pattern maker in february next year as they are too busy at present. Also negotiating with xjr5006 with some of the awesome goodies he has... have to save some more funds...

The following users liked this post:

ronbros (11-30-2015)

#50

Hi ron, couldnt find the making 500hp site you are referring to. Did manage to find a copy of the magazine though. Its on its way from your great land... trying to get more technical info on the diff bracing that lister and group44 used. Have some photos but not enough info yet. Update on the heads. Will be going back to the pattern maker in february next year as they are too busy at present. Also negotiating with xjr5006 with some of the awesome goodies he has... have to save some more funds...

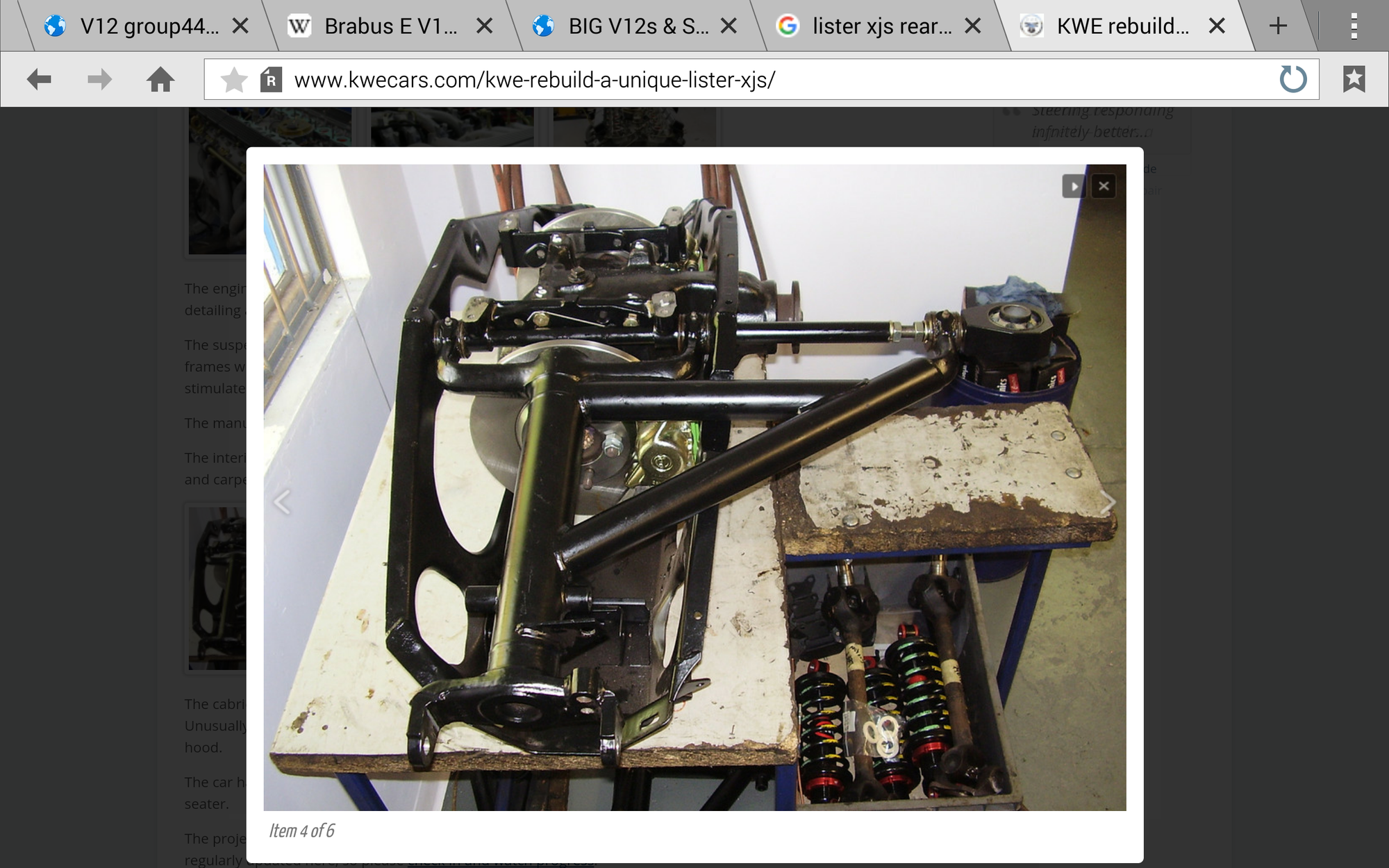

here is a pic of a Lister XJS rearend

The following 5 users liked this post by warrjon:

daddycool454 (01-09-2016),

FerrariGuy (11-29-2015),

Jonathan-W (11-30-2015),

ronbros (11-30-2015),

superchargedtr6 (11-30-2015)

#51

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

warrjon , looking at that Lister setup, they were aware of hard /gripping acceleration that could move the complete rear cage loose.

so they modified it quite a bit, deffinatly looks stronger, when i 1st got my car driving i actually tore out the 4 cage to body mounts loose(showing off).

pic of what i did to help it stay in place, lets be logical Jaguar never was into USA DRAG racing, but you know these old fashioned hotrodders!

pic of unusual drag race motorcycle, to much is not quite enough!

so they modified it quite a bit, deffinatly looks stronger, when i 1st got my car driving i actually tore out the 4 cage to body mounts loose(showing off).

pic of what i did to help it stay in place, lets be logical Jaguar never was into USA DRAG racing, but you know these old fashioned hotrodders!

pic of unusual drag race motorcycle, to much is not quite enough!

The following 3 users liked this post by ronbros:

#52

Nicely triangulated and resolves the torque issue...

great for massive power and the triangulation even helps any lateral location... not that there are much of a issue there...

http://autoweek.com/article/auctions...slides-auction

The following 2 users liked this post by Jonathan-W:

ronbros (12-01-2015),

superchargedtr6 (11-30-2015)

#53

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

i have never seen a Lister-JAG XJS in person!

but i did see in person a Lister Storm V12 at Daytona around 1997-98, it raced and was fast for a non-turbo car, but it slid off at chicane, debris on track.

the chicane is at the end of Nascar backstrech , most competitive cars are over 225 mph and sugar happens, braking into chic.

but i did see in person a Lister Storm V12 at Daytona around 1997-98, it raced and was fast for a non-turbo car, but it slid off at chicane, debris on track.

the chicane is at the end of Nascar backstrech , most competitive cars are over 225 mph and sugar happens, braking into chic.

#55

Its Christmas so I thought I would tell you how to build the rear suspension triangulated set up; used to make and supply these to the guys club racing in the UK 25 years ago.

knock out the inner wishbone shaft, check its diameter and get yourself a length of the toughest steel you can find of the same OD. Finish the end exactly as on the original shaft

Now you need to get another pair of the tubes that are used as spacers between the front and rear inner wishbone joints. The additional tube goes over the new shaft that sticks out of the front of the rear suspension frame. from where the tube ends the new shaft needs reducing to the OD of the thread on the original shaft but dont thread it yet. A heavy duty 'washer /spacer needs making with OD at last as large as the OD of the tube, if you want to be flash you can add a step for the tube to seat on. Next a spherical joint needs threading onto the reduced shaft followed by a heavy duty washer of ID of the shaft and OD just under that of the OD of the Spherical bearing. Now the shaft needs chopping off leaving a further 1" for threading as per the ends of the original shaft. Onto this thread you fit a female ended spherical joint screwing onto the thread and to tighten the whole lot up. Do this on both sides mount the whole lot up to the car and sort out brackets to then locate to the forward rose joint and weld to the chassis bolts going inwards from both go into and tighten up on a bracing cross tube appropriately threaded. This then locates the cage assembly and the floating rose joints on the shafts are used to create the inner joint of the front triangulation which I will let you work out as its straightforward.

Have fun. Merry Christmas

knock out the inner wishbone shaft, check its diameter and get yourself a length of the toughest steel you can find of the same OD. Finish the end exactly as on the original shaft

Now you need to get another pair of the tubes that are used as spacers between the front and rear inner wishbone joints. The additional tube goes over the new shaft that sticks out of the front of the rear suspension frame. from where the tube ends the new shaft needs reducing to the OD of the thread on the original shaft but dont thread it yet. A heavy duty 'washer /spacer needs making with OD at last as large as the OD of the tube, if you want to be flash you can add a step for the tube to seat on. Next a spherical joint needs threading onto the reduced shaft followed by a heavy duty washer of ID of the shaft and OD just under that of the OD of the Spherical bearing. Now the shaft needs chopping off leaving a further 1" for threading as per the ends of the original shaft. Onto this thread you fit a female ended spherical joint screwing onto the thread and to tighten the whole lot up. Do this on both sides mount the whole lot up to the car and sort out brackets to then locate to the forward rose joint and weld to the chassis bolts going inwards from both go into and tighten up on a bracing cross tube appropriately threaded. This then locates the cage assembly and the floating rose joints on the shafts are used to create the inner joint of the front triangulation which I will let you work out as its straightforward.

Have fun. Merry Christmas

The following 3 users liked this post by xjr5006:

#56

Originally Posted by xjr5006;13

[IMG

[IMG

https://cimg8.ibsrv.net/gimg/www.jaguarforums.com-vbulletin/2000x1250/80-screenshot_2015_11_18_22_17_50_1548b19e96d675d97e0 5b7f1247db5bf2c926366.png[/IMG]

70509]Its Christmas so I thought I would tell you how to build the rear suspension triangulated set up; used to make and supply these to the guys club racing in the UK 25 years ago.

knock out the inner wishbone shaft, check its diameter and get yourself a length of the toughest steel you can find of the same OD. Finish the end exactly as on the original shaft

Now you need to get another pair of the tubes that are used as spacers between the front and rear inner wishbone joints. The additional tube goes over the new shaft that sticks out of the front of the rear suspension frame. from where the tube ends the new shaft needs reducing to the OD of the thread on the original shaft but dont thread it yet. A heavy duty 'washer /spacer needs making with OD at last as large as the OD of the tube, if you want to be flash you can add a step for the tube to seat on. Next a spherical joint needs threading onto the reduced shaft followed by a heavy duty washer of ID of the shaft and OD just under that of the OD of the Spherical bearing. Now the shaft needs chopping off leaving a further 1" for threading as per the ends of the original shaft. Onto this thread you fit a female ended spherical joint screwing onto the thread and to tighten the whole lot up. Do this on both sides mount the whole lot up to the car and sort out brackets to then locate to the forward rose joint and weld to the chassis bolts going inwards from both go into and tighten up on a bracing cross tube appropriately threaded. This then locates the cage assembly and the floating rose joints on the shafts are used to create the inner joint of the front triangulation which I will let you work out as its straightforward.

Have fun. Merry Christmas

70509]Its Christmas so I thought I would tell you how to build the rear suspension triangulated set up; used to make and supply these to the guys club racing in the UK 25 years ago.

knock out the inner wishbone shaft, check its diameter and get yourself a length of the toughest steel you can find of the same OD. Finish the end exactly as on the original shaft

Now you need to get another pair of the tubes that are used as spacers between the front and rear inner wishbone joints. The additional tube goes over the new shaft that sticks out of the front of the rear suspension frame. from where the tube ends the new shaft needs reducing to the OD of the thread on the original shaft but dont thread it yet. A heavy duty 'washer /spacer needs making with OD at last as large as the OD of the tube, if you want to be flash you can add a step for the tube to seat on. Next a spherical joint needs threading onto the reduced shaft followed by a heavy duty washer of ID of the shaft and OD just under that of the OD of the Spherical bearing. Now the shaft needs chopping off leaving a further 1" for threading as per the ends of the original shaft. Onto this thread you fit a female ended spherical joint screwing onto the thread and to tighten the whole lot up. Do this on both sides mount the whole lot up to the car and sort out brackets to then locate to the forward rose joint and weld to the chassis bolts going inwards from both go into and tighten up on a bracing cross tube appropriately threaded. This then locates the cage assembly and the floating rose joints on the shafts are used to create the inner joint of the front triangulation which I will let you work out as its straightforward.

Have fun. Merry Christmas

I think this came from kwe website

Last edited by daddycool454; 12-25-2015 at 09:27 PM.

#58

Wondering if the 44 head project was moving along, fascinated to hear the next stage, read the whole post through again very slowly and carefully and wonder if the best and most cost effective way would be having the heads on 3D files, getting some chap to add some meat (just a few mm where the machining has been done. ie the top bottom and sides. Get the holes closed off where drilled; expand the size by 1.3% (thatsd the bit you needed to know) And then can the heads actually be printed to a wax suitable for lost wax casting? Might be a bit more of a pain than the normal way but you avoid the 35K + for the tooling (BTW that per head!) If you leave the ports as they are you will only have to open them smooth with flap wheels which will save a fortune on porting too.

Just my 2P worth as I would love to see if all this is possible.

Just my 2P worth as I would love to see if all this is possible.

#59

Thats definately something i will look in to. I took the heads to melbourne to be assessed by a few jaguar specialists. They were impressed with the heads. I am currently getting the heads flow tested as a benchmark to see what they are capable of straight out of the box. I will post here soon when i know the results. One of the specialists did say that the heads may be too big for a street car as is. Later this year or early next i will have 2 engines built as test beds and get some dyno testing done. It may be the case if the results come back as they said that i may get the inlet ports thickened and reduce the diameter a couple of mm. But that won't be till next year. Ill need one of your inlets and cam carriers before then for testing purposes. Shame im not in the uk, id pop down and say gday... anyway that may happen in the future... hows the inlets and cam carriers coming along?

#60

Thats definately something i will look in to. I took the heads to melbourne to be assessed by a few jaguar specialists. They were impressed with the heads. I am currently getting the heads flow tested as a benchmark to see what they are capable of straight out of the box. I will post here soon when i know the results. One of the specialists did say that the heads may be too big for a street car as is. Later this year or early next i will have 2 engines built as test beds and get some dyno testing done. It may be the case if the results come back as they said that i may get the inlet ports thickened and reduce the diameter a couple of mm. But that won't be till next year. Ill need one of your inlets and cam carriers before then for testing purposes. Shame im not in the uk, id pop down and say gday... anyway that may happen in the future... hows the inlets and cam carriers coming along?

The decision is now what bore for the cam followers/ buckets. From memory from a dozen years ago your buckets are 1.625" This is the very largest size for massive and short springs Schmittelhelm HF 4690 but usually for high reving 1.9" inlets and yours are 1.8. The 'Normal' less large diameter and taller spring uses a 1.6 bucket.

The TWR Group A inlets are off for hardening and should be back with me in a few days, the more I study them the better they are, a really really clever bit of kit. Should and no doubt would have been fitted to the XJR15 if the tooling hadn't vanished before these where made. Totally make multiple throttles redundant in all but all out racing engines and a must for hot e types and XJS's. IMHO the Jenvy system and the like are simply nasty by comparison; expensive overly complicated and inefficient. But look good to the uninitiated Guess its the difference that comes from using bits lying about + a few small castings to what I am told would be near £100K of custom top quality tooling. Still have to pinch myself that I have this kit.

You can put me down for the head files if you can get them done, A good CAD man could even alter the port sizes for individual customers and you just save files with the different versions. 35 38 40 and 42mm inlets would cover everything. Better to be able to reduce the port size than trying to increase it because of port wall thickness 's. The 44 heads I band sawed have port wall thickness down to 1mm in a couple of places!

Last edited by xjr5006; 01-10-2016 at 12:33 AM.

The following users liked this post:

Jonathan-W (01-12-2016)