My rear subframe refurbishment

#42

Good question.

Last weekend I attempted to push one out using a piece of iron 'U' section girder with a hole drilled in the middle and some threaded bar.

The tops of the 'U' section spanned the end of the a-frame either side of the bush and the threaded bar went through the U-section and bush to a large washer and nut.

I wanted to spray some wd40 or soapy water down the sides of the bush but it's too tight and I cant even get a small screwdriver down there.

So I tightened the bolt and kept tightening but the bush refused to budge.

I eventually reached the stage where if the bar had sheared it would have caused damage (or even loss of life!) as it was under so much strain - it was at that point that I bottled out and thought I should consult the forum.

Worst case is I get the local garage to do it as they have a press but I prefer to do these things myself.

Mark

#43

I see this is currently being discussed on the X300 forum

https://www.jaguarforums.com/forum/x...5/#post1119710

Opinion seems to be buying a small press or sawing them out.

I did try the drilling and sawing method trying to remove my subframe when one of the bushes had siezed to the chassis pin, I used drills, jigsaw and hacksaw blade but gave up after an hour or so as I wasn't really getting anywhere.

I wonder if one of these will be strong enough -

http://www.ebay.co.uk/itm/6-Ton-Tonn...item51c6f2e620

If I get time today I'll have a go at building a small press as I'm trying to reduce the clutter in my garage, especially as the Wife is wanting her MR2 cab in their too before it snows!

https://www.jaguarforums.com/forum/x...5/#post1119710

Opinion seems to be buying a small press or sawing them out.

I did try the drilling and sawing method trying to remove my subframe when one of the bushes had siezed to the chassis pin, I used drills, jigsaw and hacksaw blade but gave up after an hour or so as I wasn't really getting anywhere.

I wonder if one of these will be strong enough -

http://www.ebay.co.uk/itm/6-Ton-Tonn...item51c6f2e620

If I get time today I'll have a go at building a small press as I'm trying to reduce the clutter in my garage, especially as the Wife is wanting her MR2 cab in their too before it snows!

Last edited by scoobie; 12-13-2014 at 02:43 AM.

#44

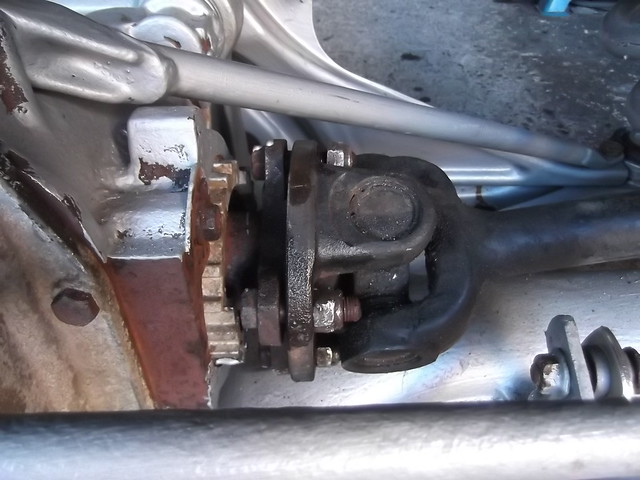

Is the pendulum bush inner sleeve bonded to the rubber (like the front lower wishbone arm bushes) or is it free to rotate?

If it is bonded then the bolt should only be torqued once the load is on the suspension.

#46

#47

The following 2 users liked this post by scoobie:

Don B (08-06-2015),

someguywithajag (03-19-2021)

#48

#49

Drill to open up big enough hole to get an electric hacksaw in and cut the rubber in a circle to get the centre metal part out, then big manual hacksaw from inside (thread the blade through) and cut two slots 10mm apart, drift out the 10mm bit and the bush can then be compressed and taken out.

I'm sure there must be an easier way but I couldn't see it.

I think if you tried to push these out it may distort the a-frame pressing as they were well stuck in place.

I'm sure there must be an easier way but I couldn't see it.

I think if you tried to push these out it may distort the a-frame pressing as they were well stuck in place.

The following users liked this post:

someguywithajag (03-19-2021)

#50

If this were part of a cooling system in a nuclear reactor I would be shouting 'run', but as its just the jag I think it will suffice.

There are three layers there and I cut the final layer a bit wider than the original, folded it over and tacked it - just to give a bit extra strength.

Touch of the 2-pack rust-busters paint and its looking good

There are three layers there and I cut the final layer a bit wider than the original, folded it over and tacked it - just to give a bit extra strength.

Touch of the 2-pack rust-busters paint and its looking good

#51

The parts that really concern me though is around the box section where the springs and shocks seat as they appear to take the whole weight of the rear of the vehicle.

Mine had some rusty parts (AKA looks like there is no rust until you scrape the paint off) but were difficult to reach with any of the tools I had (especially lying on your back under the car) so I purchased a flexible extension for my drill - worked a treat

Mine had some rusty parts (AKA looks like there is no rust until you scrape the paint off) but were difficult to reach with any of the tools I had (especially lying on your back under the car) so I purchased a flexible extension for my drill - worked a treat

#52

For the welding, I can't recommend this stuff enough

It was around £12 from Halfords but I think its a US product - absolutely brilliant for painting the rear of the metal pieces being welded into place especially on the chassis members where there's a 3 layer sandwich.

Its also good for when you are part way through a job and you spray a thin coat onto the metal so when you return to it days later there's no corrosion you need to clean off.

It doesn't seem to affect the mig arc in any way - if anything it helps it.

It was around £12 from Halfords but I think its a US product - absolutely brilliant for painting the rear of the metal pieces being welded into place especially on the chassis members where there's a 3 layer sandwich.

Its also good for when you are part way through a job and you spray a thin coat onto the metal so when you return to it days later there's no corrosion you need to clean off.

It doesn't seem to affect the mig arc in any way - if anything it helps it.

The following users liked this post:

RaceDiagnostics (03-17-2015)

#53

Have you made a decision on freeing up the wishbone inner fulcrum pins?

See post #8 below for my reasoning:

https://www.jaguarforums.com/forum/x...emoval-137740/

See post #8 below for my reasoning:

https://www.jaguarforums.com/forum/x...emoval-137740/

#54

Plums - I had intended on leaving them be, other than giving them a good dose of waxoil/dinitrol - whatever seemed to flow and cover the best.

Plus I think my fulcrum bearings are working as they should its just the corrosion on the inside part of the bolts that is stopping them being drifted out (and I haven't tried bashing them too hard in case i disturb the bearings)

The rest of the wishbone assy is now de-rusted and painted and the fulcrum bearlings give no indication of any play so my plan was to fix what was bust or worn, replace known issues where appropriate or simple and try not to make too much (possibly unnecessary) additional work.

However, I now know if I ever need to drop the suspension again (to change things like the fulcrum bolts), now everything will be clean and well greased, that it should only take a few hours

Plus I think my fulcrum bearings are working as they should its just the corrosion on the inside part of the bolts that is stopping them being drifted out (and I haven't tried bashing them too hard in case i disturb the bearings)

The rest of the wishbone assy is now de-rusted and painted and the fulcrum bearlings give no indication of any play so my plan was to fix what was bust or worn, replace known issues where appropriate or simple and try not to make too much (possibly unnecessary) additional work.

However, I now know if I ever need to drop the suspension again (to change things like the fulcrum bolts), now everything will be clean and well greased, that it should only take a few hours

Last edited by scoobie; 03-17-2015 at 05:14 PM.

#55

If we are speaking of the inner fulcrum shaft that passes through the

two bushes on each side of the differential frame, there are no bearings

in the third generation irs as found in the 2000 XK8.

There are only the bushes and the pin passes through the two plain bores

on the inner end of the wishbone. There is some speculation that those

bores may be bronze bushed but no confirmation so far.

Of course, my thoughts that the wishbone is intended to rotate freely

around the pin are exactly that ... thoughts unconfirmed by anyone else.

Maybe they are meant to tighten up as a single solid unit against the bush

rubber in the end given the effect of tightening the nut on the shaft

compressing against the inner sleeve of the bush. Completely plausible.

Carry on then

++

two bushes on each side of the differential frame, there are no bearings

in the third generation irs as found in the 2000 XK8.

There are only the bushes and the pin passes through the two plain bores

on the inner end of the wishbone. There is some speculation that those

bores may be bronze bushed but no confirmation so far.

Code:

crude ascii art

bush - bore - exposed - bore - bush

-- == == --

==================================

-- == == --

========================

========================

========================

========================

========================

========================

========================

not everything lined up horizontally no matter how many spaces I removed.

Of course, my thoughts that the wishbone is intended to rotate freely

around the pin are exactly that ... thoughts unconfirmed by anyone else.

Maybe they are meant to tighten up as a single solid unit against the bush

rubber in the end given the effect of tightening the nut on the shaft

compressing against the inner sleeve of the bush. Completely plausible.

Carry on then

++

Last edited by plums; 03-17-2015 at 06:12 PM.

#56

Ascii art - LOL - the good old days!

Mine move (sort of) freely, but the overall range of movement is limited to (i think) the twisting effects of the rubber in the bush.

For example they operate over the normal range of springs/dampers but they would not be able to fold back on themselves, e.g. to put the assembly in the boot of a car

Mine move (sort of) freely, but the overall range of movement is limited to (i think) the twisting effects of the rubber in the bush.

For example they operate over the normal range of springs/dampers but they would not be able to fold back on themselves, e.g. to put the assembly in the boot of a car

#57

Ascii art - LOL - the good old days!

Mine move (sort of) freely, but the overall range of movement is limited to (i think) the twisting effects of the rubber in the bush.

For example they operate over the normal range of springs/dampers but they would not be able to fold back on themselves, e.g. to put the assembly in the boot of a car

Mine move (sort of) freely, but the overall range of movement is limited to (i think) the twisting effects of the rubber in the bush.

For example they operate over the normal range of springs/dampers but they would not be able to fold back on themselves, e.g. to put the assembly in the boot of a car

Given the amount of time consumed so far in disassembly it's a good

thing that my seller ended up delivering by truck.

In the process of writing out the previous post, I think the existing situation

of limited movement is quite acceptable. After all, when tightened, the inner

sleeve of the rubber bushes cause the affected parts to act as a solid unit.

This is similar to the arrangement on the front arms.

#58

And of course the advice on fitting new front lower arms is do not tighten until the car is on its wheels (so that the rubber bush is in a neutral position under normal circumstances).

I don't think I could find that advice for the rear assembly which would seem odd.

#59

#60

I bought my 2004 XK8 last november and over the winter did the best I could do on the bottom with POR15. The underbody is good and solid with no invasive corrosion but the rear suspension pack is pretty rusted. I did the best I could to clean up the surface rust and protect exposed areas until I have next winter to go at the rear end. I am up here in Canada and I suspect this car may have seena little road salt in its lifetime. I work in the auto parts business and one of my suppliers does Zinc Plating for us. He said when you get the parts all off let me have em and hewill run them through his derusting solutions ans zinc plate everythign for me. I know I am the only one that will see it, but I think that will look pretty sharp. I will continue to follow your project with interest.