Brake Puzzle. Suggestions please!

#1

As posted previously, I have been fighting a hard right pull from the brakes. Initially, this would last until I had applied the brakes hard about 6 times, and then stop pulling. It seemed to revert to pulling 'mode' after being parked for 15 minutes or so, and could then be corrected in the same manner.

I bled the left front caliper 'by foot pedal' and, when that didn't work, using 12 psi from a pressure bleeder. No air was seen, but also no difference was made. I could blow through the hose, so it seemed like the caliper must be at fault, so I ordered a rebuilt unit.

After installing same, along with a new hose (blows clear) I could not get any brake fluid from the caliper. Checked the nipple: clear. Even left the nipple out; still couldn't get fluid by foot pedal. Pedal feels hard as it would if the brakes had nowhere to go. Reinstalled the pressure bleeder: no change.

'wire rodded ' the old caliper through the nipple hole: clear to the bottom of the cylinder cavity. Rodded the new caliper and detected resistance. Assumed that the caliper must have some internal obstruction. Ordered a replacement.

Removed the rebuild caliper unit, reattached the hose at the steel line end, and fed into a jar. Pedal hard as rock; no joy with the pressure bleeder either.

Started the car, thinking that various things - vacuum assist, anti-lock brake module, etc., would become active and alter something: no change: pedal still hard, no brake fluid from hose.

I could surely use some urgent guidance on this one. Any ideas welcome. Thanks.

I bled the left front caliper 'by foot pedal' and, when that didn't work, using 12 psi from a pressure bleeder. No air was seen, but also no difference was made. I could blow through the hose, so it seemed like the caliper must be at fault, so I ordered a rebuilt unit.

After installing same, along with a new hose (blows clear) I could not get any brake fluid from the caliper. Checked the nipple: clear. Even left the nipple out; still couldn't get fluid by foot pedal. Pedal feels hard as it would if the brakes had nowhere to go. Reinstalled the pressure bleeder: no change.

'wire rodded ' the old caliper through the nipple hole: clear to the bottom of the cylinder cavity. Rodded the new caliper and detected resistance. Assumed that the caliper must have some internal obstruction. Ordered a replacement.

Removed the rebuild caliper unit, reattached the hose at the steel line end, and fed into a jar. Pedal hard as rock; no joy with the pressure bleeder either.

Started the car, thinking that various things - vacuum assist, anti-lock brake module, etc., would become active and alter something: no change: pedal still hard, no brake fluid from hose.

I could surely use some urgent guidance on this one. Any ideas welcome. Thanks.

Last edited by GGG; 09-20-2020 at 02:54 PM. Reason: Edit typo in thread title

The following users liked this post:

redpoptop (09-12-2020)

#2

I see you have done all I would do.

Now, the only thing I can think of, is a pinched line between the master and the caliber.

Are you getting front brakes on the other side? Generally the side that is pulling is the side that is working, as the other wheel is free wheeling.

If you have run over something, that would be the problem, same as someone using a plumbing pressure fitting in a brake line and tightening it up where it doesn't release the pressure in the calibers or wheel cylinder.

Now, the only thing I can think of, is a pinched line between the master and the caliber.

Are you getting front brakes on the other side? Generally the side that is pulling is the side that is working, as the other wheel is free wheeling.

If you have run over something, that would be the problem, same as someone using a plumbing pressure fitting in a brake line and tightening it up where it doesn't release the pressure in the calibers or wheel cylinder.

#3

Thanks:

No damage or anything like that. Brakes were (sort of) working when I brought the car inside for the caliper replacement.

No OBDII codes being generated, and no fault lights on dash. No matter how hard I bear down on the brake pedal, I can't get a drop of fluid from the now-open brake line. Car starts normally.

No idea why it would have happened now, when I had no problem doing the exact same bleeding operation twice before, but I am wondering whether there is a so-called proportioning valve in the brakes front / rear, with a differential pressure shuttle that could move to block what it thinks is a broken line. In this case, it would be thinking that a front brake line is blown, and therefore blocks the fronts to allow the rears to still function. That might create the symptoms EXCEPT that I would have thought a brake fault light would get generated. Does anyone know where this unit might be and how to go about checking / resetting the device?

No damage or anything like that. Brakes were (sort of) working when I brought the car inside for the caliper replacement.

No OBDII codes being generated, and no fault lights on dash. No matter how hard I bear down on the brake pedal, I can't get a drop of fluid from the now-open brake line. Car starts normally.

No idea why it would have happened now, when I had no problem doing the exact same bleeding operation twice before, but I am wondering whether there is a so-called proportioning valve in the brakes front / rear, with a differential pressure shuttle that could move to block what it thinks is a broken line. In this case, it would be thinking that a front brake line is blown, and therefore blocks the fronts to allow the rears to still function. That might create the symptoms EXCEPT that I would have thought a brake fault light would get generated. Does anyone know where this unit might be and how to go about checking / resetting the device?

#4

I understand and comply with your suggestion about the valve. We had the same issue with the TR's, well, we still do, if a car is original.

I would get someone to apply the brakes and undo the connection at the master, if good there , go to the next union. Sorry have not gone over the brake lines in my Jaguar, been lucky, knock on wood.

I would get someone to apply the brakes and undo the connection at the master, if good there , go to the next union. Sorry have not gone over the brake lines in my Jaguar, been lucky, knock on wood.

#7

OK, I now have the answer: I checked the right front brake and had no problem bleeding the caliper. That indicated that the problem was either at the ABS or the right front brake line, and not the master cylinder, otherwise both would be affected. I disconnected the LH brake caliper line at the ABS and there was no fluid. Put on pedal pressure, and 12 psi from the pressure bleeder, no fluid. Therefore, whatever valve device is in there is jammed as tight as can be and / or blocked totally with a broken seal .

For good measure, I 'rodded' the brake line with thin aircraft cable: no obstructions. To be certain of the conclusion, I removed the right hand brake line and, of course, saw plenty of fluid.

So now, if anyone has taken one of these valve blocks apart, please let me know. At the same time I am checking for repair services: I saw one posting for Automotive Scientific, and sent an inquiry. Look like $500 + a pop, so I would prefer to give it a shot myself, if at all feasible. Thanks for all the input.

For good measure, I 'rodded' the brake line with thin aircraft cable: no obstructions. To be certain of the conclusion, I removed the right hand brake line and, of course, saw plenty of fluid.

So now, if anyone has taken one of these valve blocks apart, please let me know. At the same time I am checking for repair services: I saw one posting for Automotive Scientific, and sent an inquiry. Look like $500 + a pop, so I would prefer to give it a shot myself, if at all feasible. Thanks for all the input.

The following users liked this post:

michaelh (09-13-2020)

Trending Topics

#9

Atlastajag1,

Well done tracing the cause to the ABS Hydraulic Valve block. Your failure mode suggests an isolation valve is jammed closed (there is one per wheel). These are plunge valves closed by a solenoid and opened by spring return. Jams are rare due to the high factor of safety. There are 4 root causes that I can think of:-

1. ABS Module is faulty and permanently sending current to actuate solenoid. Doubtful.

2. Water in brake oil is beyond safe Hydroscopic threshold which has corroded valve bodies and Springs. Likely.

3. Particulates in the oil have jammed the valve seal OD in closed position. Likely.

4. Valve return spring is broken. Unlikely.

If you have either 1, or 2, then you need to change the whole unit due to unrecoverable conditions. If you have 3, or 4, then a valve body strip down, clean, flush and fix could potentially work. HOWEVER. This is a complex and precision unit and to disassemble it takes experience and great care. There is the added consideration that your life could depend on the integrity of the fix.

Personally, I would strip it down, knowing that I have to remove it and have 50% chance of having to buy one anyway (nothing to lose!). If you don't feel confident then don't risk it and buy a replacement. Used units are OK, but please flush and prime with NEW brake fluid when installing.

Well done tracing the cause to the ABS Hydraulic Valve block. Your failure mode suggests an isolation valve is jammed closed (there is one per wheel). These are plunge valves closed by a solenoid and opened by spring return. Jams are rare due to the high factor of safety. There are 4 root causes that I can think of:-

1. ABS Module is faulty and permanently sending current to actuate solenoid. Doubtful.

2. Water in brake oil is beyond safe Hydroscopic threshold which has corroded valve bodies and Springs. Likely.

3. Particulates in the oil have jammed the valve seal OD in closed position. Likely.

4. Valve return spring is broken. Unlikely.

If you have either 1, or 2, then you need to change the whole unit due to unrecoverable conditions. If you have 3, or 4, then a valve body strip down, clean, flush and fix could potentially work. HOWEVER. This is a complex and precision unit and to disassemble it takes experience and great care. There is the added consideration that your life could depend on the integrity of the fix.

Personally, I would strip it down, knowing that I have to remove it and have 50% chance of having to buy one anyway (nothing to lose!). If you don't feel confident then don't risk it and buy a replacement. Used units are OK, but please flush and prime with NEW brake fluid when installing.

#10

Very rare for an ABS hydraulic unit to fail - hence usually cheap from a breaker. Pull the power to the ABS unit which is the small plug under the large one, or the fuse if easier. Then try the pressure bleeder, that will eliminate or not the electronics side - I would suspect it eliminated as light would come on.

#11

Good input gentlemen! Thanks. The plan is, then, to pull the entire assembly, and see if I can free up the valve. Also to inspect the return spring. As you say, I have nothing to lose in pulling the valve body apart, if such can be done. The history of this failure is that it began with the brakes pulling noticeably but that the pull would self correct after the car had been parked for a short time. Also that after several hard brake applications, the problem would disappear. After sitting for a longer time, the problem would return. Eventually, the valve did not return home at all, and now the thing is 100% blocking. So it is possible that engine heat initially aided the valve recovery, along with fluid pressure.

I have decent electro-mech skills, so unless there is some special tool or fixture needed to reassemble it, and the valve can be satisfactorily cleaned and operated, I am not worried about the safety issue. It is interesting that the manual states that the ABS/TC/SC module doesn't interfere with normal braking operation. Hmmm.

I am not having ABS faults, so the infamous solder joints are intact. The question is whether to assume that they will eventually fail and to reflow the solder whilst the controller is handy. Either way, I wouldn't replace the controller itself with some unknown, even if I had to find a valve body. But it seems as though people sell the entire unit, rather than just the valve body.

I'll publish anything worthwhile that comes out of this attempt.

Cheers

I have decent electro-mech skills, so unless there is some special tool or fixture needed to reassemble it, and the valve can be satisfactorily cleaned and operated, I am not worried about the safety issue. It is interesting that the manual states that the ABS/TC/SC module doesn't interfere with normal braking operation. Hmmm.

I am not having ABS faults, so the infamous solder joints are intact. The question is whether to assume that they will eventually fail and to reflow the solder whilst the controller is handy. Either way, I wouldn't replace the controller itself with some unknown, even if I had to find a valve body. But it seems as though people sell the entire unit, rather than just the valve body.

I'll publish anything worthwhile that comes out of this attempt.

Cheers

The following users liked this post:

Johnken (09-14-2020)

#12

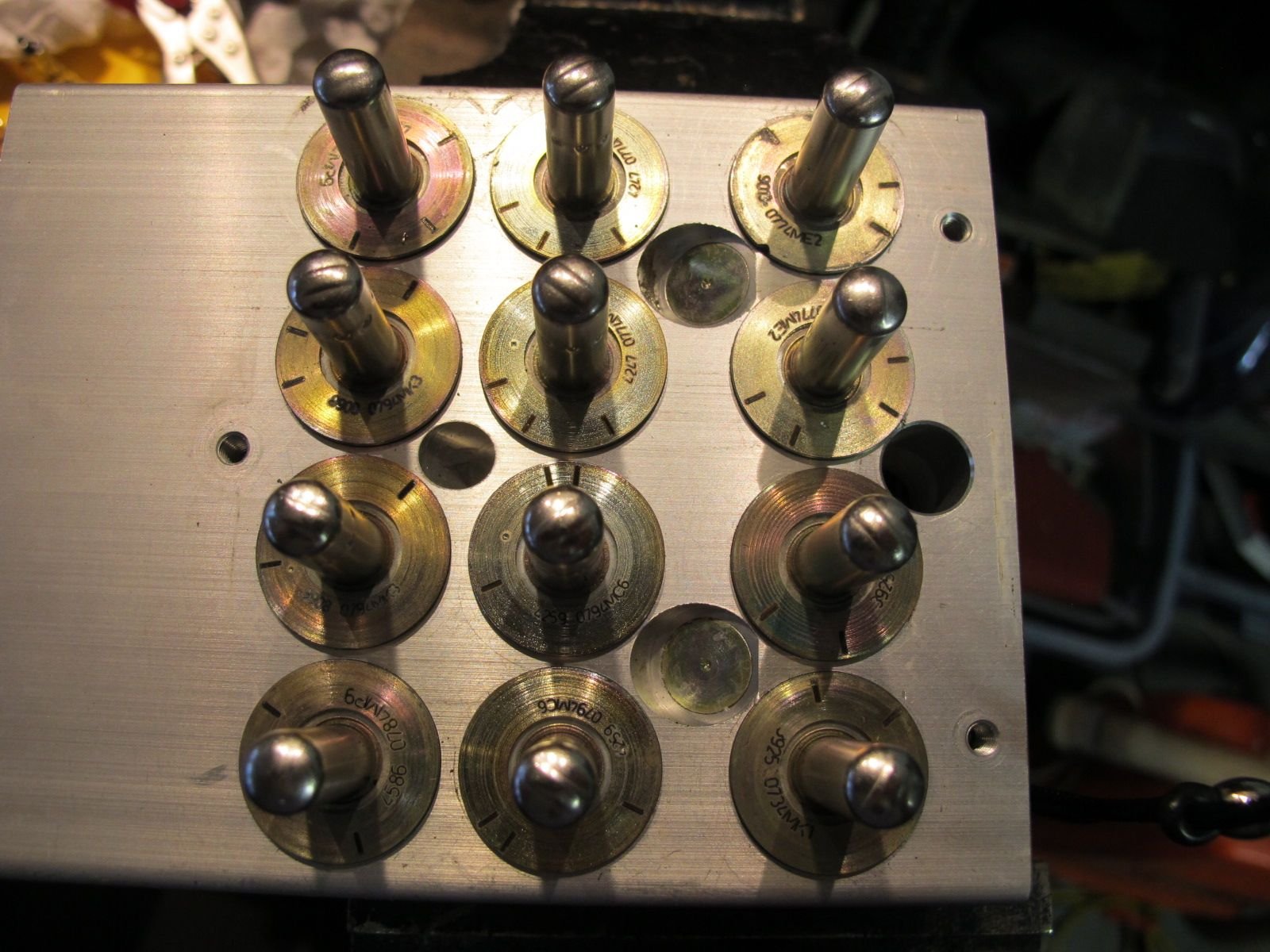

So I have the ABS apart on the bench. If anyone can comment on the following I would be grateful: I had convinced myself that the issue was a stuck valve, but the valves are all exactly at the same height. Wouldn't one of them be out of position, whether high or low? Also, I cannot move any of them, either up or down (assuming that they are in the center position). I wrapped the stem with silicone rubber, so as not to mar the surface, and got a grip on them with vice grips. Unless those things have springs on them the heft of engine valve springs (or I am getting even more feeble in my old age) I cannot move them. It would be surprising if those small solenoids could push/ pull them out of position, when I can't move them even a fraction.

Does anyone have an idea how to get those valves out? Since the valves are embedded in a solid aluminum block, they must each be screwed in place, but there is only a blank disc on each valve. Any idea?

Does anyone have an idea how to get those valves out? Since the valves are embedded in a solid aluminum block, they must each be screwed in place, but there is only a blank disc on each valve. Any idea?

#13

OK, so you’ve separated the black solenoid module from the aluminium valve body and this has exposed the valve sleeves. The actual moving valve stems are not yet visible, they are within the hollow sleeves that you have tried to push!

Here is a video showing the destructive dismantling of a similar ABS unit sleeve. Jump to 7:54 minutes to see what I'm trying to explain (it's only 30seconds!)..

I found a video on YouTube showing the oil flow in the ABS valve block which is interesting – strong accent tho!. Whilst this example is for a Motorbike, the principle is identical.

With respect to dismantling, the old Ford Bosch ones were screwed in but I don’t know about our later Jaguar ones. There should be a removable seal around each sleeve. Can this seal be easily removed to reveal anything beneath? If the valves are pressed in then this may not be a serviceable unit. Can you upload some images?

Here is a thread of a Jag X-Type owner with a similar problem to you. He managed to unblock his valve with Compressed Air and flush. Ultimately caused by water in the oil.... https://www.jaguarforums.com/forum/x...-valve-188478/

Here is a video showing the destructive dismantling of a similar ABS unit sleeve. Jump to 7:54 minutes to see what I'm trying to explain (it's only 30seconds!)..

I found a video on YouTube showing the oil flow in the ABS valve block which is interesting – strong accent tho!. Whilst this example is for a Motorbike, the principle is identical.

With respect to dismantling, the old Ford Bosch ones were screwed in but I don’t know about our later Jaguar ones. There should be a removable seal around each sleeve. Can this seal be easily removed to reveal anything beneath? If the valves are pressed in then this may not be a serviceable unit. Can you upload some images?

Here is a thread of a Jag X-Type owner with a similar problem to you. He managed to unblock his valve with Compressed Air and flush. Ultimately caused by water in the oil.... https://www.jaguarforums.com/forum/x...-valve-188478/

Last edited by PKWise; 09-15-2020 at 04:49 AM.

#14

I'll get a photo uploaded today. I have a possible replacement block (used) supplier. The ending of the p/n is AB rather than AC. The man tells me this is related to software. If so, it shouldn't matter because I plan on swapping the control board for mine. It is rumored that Jag dealers are involved in programming any new controller that gets installed. Heavens forbid! It still seems unlikely that the controller / solenoid board is causing a problem, because that would imply that a solenoid would have to position a valve correctly for normal running, and I don't think that is the case.

Can we confirm which way the valve is operated; into the block, toward the pump, or outwards toward the solenoid?

The other concern is bleeding the block after all this blowing of air and fluid. I read that used, re-conned or new blocks are always left full of fluid. Is there a published procedure, does anybody know? Although I have the pedal depressed 6 cm and no floods ensued when I disconnected lines, there is an inch or so of drop for the two large diameter tubes as they attach to the block. Any air in there would, presumably end up in the block.

Can we confirm which way the valve is operated; into the block, toward the pump, or outwards toward the solenoid?

The other concern is bleeding the block after all this blowing of air and fluid. I read that used, re-conned or new blocks are always left full of fluid. Is there a published procedure, does anybody know? Although I have the pedal depressed 6 cm and no floods ensued when I disconnected lines, there is an inch or so of drop for the two large diameter tubes as they attach to the block. Any air in there would, presumably end up in the block.

#15

OK, here are a couple of shots of the valve assy. I have applied air pressure in the reverse direction whilst covering the unused line, and feeling the pressure back at the inlet line opening. It then compared the 'good' brake feed with the supposedly blocked one. I then went over to the rear brake circuits and did the same thing. There is no difference that I can discern, between any of the four circuits. Obviously, putting 80 psi on without a sealed fitting is a bit crude, and all I have is the judgement as to whether a fingertip is being lifted the same everywhere, but close enough. Although the volume of air going through the valve circuits seems to me to be very low, they are all the same, give or take, there is no sign of a blockage or a stuck valve. As the man said: "I hate when that happens"!

Looking at the what I thought were valve stems, and being unable to move them, it occurred to me that they may not be the valve stems, but boots over the stems to keep any valve leakage inside the block, and not able to contaminate the solenoids etc. If so, these boots would have to come off to manipulate the valves, and I don't know how to do that.

The decision is whether to 'assume' that I have cleared the obstruction (no evidence has been seen in fluid) and re-assemble, of get another block (of unknown service readiness), learn how to reliably bleed out the air, learn how to deal with the air gap in the two feeder tubes, to ensure I don't have to do all this over again!

#16

I think you’ve done the right approach.

Those valves appear to be pressed in (there’s no apparent feature to screw them in) and any attempt to pull them out will lead to damage to the sleeves and compromise the interference fit when you re-assemble into the aluminium body. So I would abort attempts to pull them out. This leaves you with one final option. Which is to copy fellow member ‘Gophat’ who solved his identical problem by soaking the internals with rust remover. Agree this is unorthodox but it worked for him (it won’t damage the Aluminium).

Gophat - “I raised my compressor up to about 60psi and blew air into the FR and RL ports. MC2 shot rusty particles out. I put a bit of '3-in-1' rust remover in the ports and let it sit a couple minutes. This is usually a big NO, only brake fluid should go in there. Being that I was at the point of no return, I tried it. I blew some more air after the rust remover soaked the valves. More rusty particles came out. I lowered the PSI back down to 30 and blew more compressed air until it was particle free.

I flushed the system with fresh brake fluid and it bled as normal. Rust free and the brake fluid is crystal clear. my pedal is back to normal. I even slammed the brakes a few times to see if it would get the abs pump valves stuck again but it didn't I guess the valves are free now.”

If you do this and it yields rust particles, then it would at least confirm the root cause to your problem.

In answer to your earlier question about valve travel direction, there is no easy way to determine this. The stems and springs are hidden and so are the solenoid winding/current directions. These are single direction solenoids (for Fail-safe reasons) so they either push or pull. Not both. The inner spring returns the plunger. It could be a mix of both types and only a strip-down, electrician, or engineering drawing could correctly answer the question.

Those valves appear to be pressed in (there’s no apparent feature to screw them in) and any attempt to pull them out will lead to damage to the sleeves and compromise the interference fit when you re-assemble into the aluminium body. So I would abort attempts to pull them out. This leaves you with one final option. Which is to copy fellow member ‘Gophat’ who solved his identical problem by soaking the internals with rust remover. Agree this is unorthodox but it worked for him (it won’t damage the Aluminium).

Gophat - “I raised my compressor up to about 60psi and blew air into the FR and RL ports. MC2 shot rusty particles out. I put a bit of '3-in-1' rust remover in the ports and let it sit a couple minutes. This is usually a big NO, only brake fluid should go in there. Being that I was at the point of no return, I tried it. I blew some more air after the rust remover soaked the valves. More rusty particles came out. I lowered the PSI back down to 30 and blew more compressed air until it was particle free.

I flushed the system with fresh brake fluid and it bled as normal. Rust free and the brake fluid is crystal clear. my pedal is back to normal. I even slammed the brakes a few times to see if it would get the abs pump valves stuck again but it didn't I guess the valves are free now.”

If you do this and it yields rust particles, then it would at least confirm the root cause to your problem.

In answer to your earlier question about valve travel direction, there is no easy way to determine this. The stems and springs are hidden and so are the solenoid winding/current directions. These are single direction solenoids (for Fail-safe reasons) so they either push or pull. Not both. The inner spring returns the plunger. It could be a mix of both types and only a strip-down, electrician, or engineering drawing could correctly answer the question.

Last edited by PKWise; 09-15-2020 at 03:26 PM.

#17

Agreed! As for the rust remover flush, I am tempted to reply on the fact that the previously blocked line seems to allow roughly the same airflow / pressure as the healthy circuits. As said, I am underwhelmed by how small an airflow these circuits seem to allow through, but I do have airflow on the left front circuit where before there was zero hydraulic flow, and all others are similar. It would be marvelous to know what airflow was like on Gophat's valve block.

I'll see whether rust remover (PB Blaster) will mix with DOT 4 before escalating the flushing. If it doesn't, I will pass on that approach.

Thanks again for your interest and helpful comments!

I'll see whether rust remover (PB Blaster) will mix with DOT 4 before escalating the flushing. If it doesn't, I will pass on that approach.

Thanks again for your interest and helpful comments!

#18

A little followup: tests indicate (2) varieties of rust remover are not miscible with S/DOT4, so Having got air to pass equally back and forth in the ABS block, I am not going to temp fate. Not realizing (I think) that the air problem with ABS units has to do with getting air into the pump, rather than into the distribution passages, I drew fluid into the feed side, using a MityVac on each of the brake line sides, and left it at that. Risking a violent reaction from breaking the rule of 'If it ain't broke..." I pulled the controller apart and re-flow soldered all the connector pins, solenoid pads, and the power pins.

If I am correct, air in the two brake supply lines should get bled out when bleeding at the wheels, and not get into the pump itself. Comments please!

Also, I note, after bleeding all all lines, that on modern ABS cars it is possible to purge the pump using an Autec OBDII device (and then re-bleeding all the all the lines again!!

I don't know whether that ABS Self Service Mode will work on the XK8?

Also that the brute force method (see John Dee's To the Garage video) can work.

Until I get back on the road and find some sand to lock up on, I won't know if there is air in the pump.

If I am correct, air in the two brake supply lines should get bled out when bleeding at the wheels, and not get into the pump itself. Comments please!

Also, I note, after bleeding all all lines, that on modern ABS cars it is possible to purge the pump using an Autec OBDII device (and then re-bleeding all the all the lines again!!

I don't know whether that ABS Self Service Mode will work on the XK8?

Also that the brute force method (see John Dee's To the Garage video) can work.

Until I get back on the road and find some sand to lock up on, I won't know if there is air in the pump.

#19

Well done.

There is obvious benefit in priming the ABS valve block with fluid prior to full connection to minimise Air in the system.

However, the ABS unit and pipe routes to/from it, are orientated and designed in such a way that it can be filled with fluid and bled free of Air pockets in the normal way. The system is actually full of air in the factory assembly line, but they draw a vacuum to fill it !!

For bleeding, there is a wheel sequence guideline of Front left, Front Right, then Rear Left, Rear Right. The use of a low pressure fill is recommended which is conveniently shown and described in this vid

Agree you’ll definitely have to test the system in a safe manner. Fingers crossed for you.

There is obvious benefit in priming the ABS valve block with fluid prior to full connection to minimise Air in the system.

However, the ABS unit and pipe routes to/from it, are orientated and designed in such a way that it can be filled with fluid and bled free of Air pockets in the normal way. The system is actually full of air in the factory assembly line, but they draw a vacuum to fill it !!

For bleeding, there is a wheel sequence guideline of Front left, Front Right, then Rear Left, Rear Right. The use of a low pressure fill is recommended which is conveniently shown and described in this vid

Agree you’ll definitely have to test the system in a safe manner. Fingers crossed for you.

Last edited by PKWise; 09-17-2020 at 01:53 PM.

#20

Here endeth the lesson: the problem of pulling hard to the right has been rectified. Having eliminated the caliper and rubber hose (at considerable expense, and time, due to attributing the lack of bleed-ability at the right front to a defective replacement caliper, and having to order another replacement) the issue has gone away, after force-flushing all passageways in the ABS block, reinstalling, bleeding the feed lines to the block, filling / bleeding all ports on the block using an eye dropper and a MityVac (and creating a mess), and finally bleeding all four corners.

There was very little evidence produced by all this flushing and air blasting, except a tiny fragment of what might have been a seal. That may mean I am not permanently out of the woods, but the brakes are normal again, for now.

I have tested the ABS in a limited, low- speed way on some heavy driveway stone, but I am looking for some nice sand to do a speed test on, as the stones made such a racket I couldn't hear the ABS pump.

There was no evidence of air in the pump, as a result of the ABS emergency stop, as the pedal travel and feel was unchanged. As I understand it, the pump itself would not get drained by doing what I did; the passages seem to contain fluid that drains (or gets blown out), and I was expecting some grief as a result.

Does anyone know whether the Autozones of the world loan out Autel units that can service test the ABS?

Many thanks again for everyone's interest and suggestions.

There was very little evidence produced by all this flushing and air blasting, except a tiny fragment of what might have been a seal. That may mean I am not permanently out of the woods, but the brakes are normal again, for now.

I have tested the ABS in a limited, low- speed way on some heavy driveway stone, but I am looking for some nice sand to do a speed test on, as the stones made such a racket I couldn't hear the ABS pump.

There was no evidence of air in the pump, as a result of the ABS emergency stop, as the pedal travel and feel was unchanged. As I understand it, the pump itself would not get drained by doing what I did; the passages seem to contain fluid that drains (or gets blown out), and I was expecting some grief as a result.

Does anyone know whether the Autozones of the world loan out Autel units that can service test the ABS?

Many thanks again for everyone's interest and suggestions.