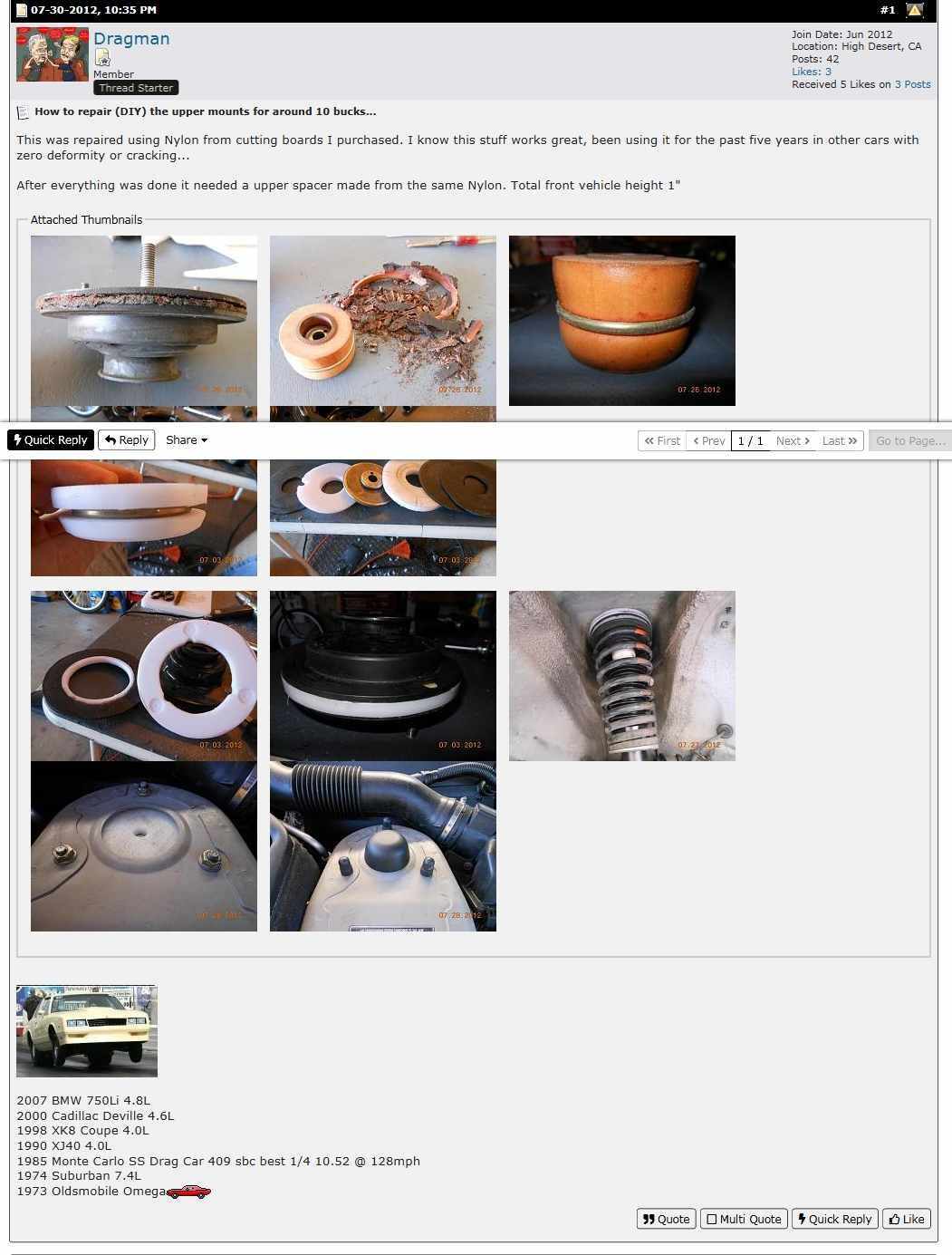

cutting board upper shock mounts

#1

Hi everyone,

The recent posts @ welsh upper mounts has changed my desire to just pop down the money for the easiest, quickest approach (with price being a consideration)

In my opinion, 2 or 3 years life span is not acceptable for a product like this.

I recall finding several posts (years ago) about an individual that rebuilt his mounts using cutting board material. At the same time I found a posting from a hot rodder that rebuilt these types of mount and he even listed the materials and supplier he used.

If anyone could steer me toward any of these older posts I would appreciate it.

I'm prepared to get a few sets turned to the proper sizing if I can find some of this older guidance.

wj

The recent posts @ welsh upper mounts has changed my desire to just pop down the money for the easiest, quickest approach (with price being a consideration)

In my opinion, 2 or 3 years life span is not acceptable for a product like this.

I recall finding several posts (years ago) about an individual that rebuilt his mounts using cutting board material. At the same time I found a posting from a hot rodder that rebuilt these types of mount and he even listed the materials and supplier he used.

If anyone could steer me toward any of these older posts I would appreciate it.

I'm prepared to get a few sets turned to the proper sizing if I can find some of this older guidance.

wj

#2

From memory, the cutting board was used in addition to the new mount for the purpose of restoring ride height. I understood it to be an additional layer between the top part of the mount and the metal shock tower. You figure a 3/8" or so filler with the shock base attached partway down the lower control arm might restore the better part of 1" of ride height.

#3

From memory, the cutting board was used in addition to the new mount for the purpose of restoring ride height. I understood it to be an additional layer between the top part of the mount and the metal shock tower. You figure a 3/8" or so filler with the shock base attached partway down the lower control arm might restore the better part of 1" of ride height.

thanks for the reply.

wj

#5

I never saw that post before, interesting as it seems this need has been around for a while.

The one particular post I'm looking for actually have images of the poster turning the white material on a lathe with a large stack of the material on the floor...and of course a beautiful finished product with WHITE where we always see yellow, black or redish pink. thanks for the effort. I think he was retired and living in florida.

wj

The one particular post I'm looking for actually have images of the poster turning the white material on a lathe with a large stack of the material on the floor...and of course a beautiful finished product with WHITE where we always see yellow, black or redish pink. thanks for the effort. I think he was retired and living in florida.

wj

#6

#7

On the stock foam mounts, the foam flattens into a pancake, specially the outer doughnut, the inner one crumbles. On the Welsh urethane mount, the outer doughnut seems to be everlasting, but the inner bush seems to have a weakness to strong horizontal forces. At least, Welsh's mounts save your tires, but yes I agree. It can't be too hard for them to reinforce the inner bush.

Trending Topics

The following users liked this post:

DavidYau (04-28-2020)

#10

Very interesting stuff. Obviously the quality/durability of the shock mounts themselves is an issue. But in addition to this, the springs apparently fatigue (?), resulting in lower ride height. I'm sure I'm not the first to think of using spacers to compensate for this. I was hoping that someone else had tried spacers, and could offer some advice as to thickness and material. Lacking any more info, I will try cutting spacers from white cutting-board material, probably about 3/8" thick or a little more. I plan to drill three holes in each spacer for the top-side studs. The spacer will then end up on top of the shock mount, adding to its total thickness.

Comments? Experiences??

Bob Frisby

Boise, Idaho

'99 XK8

'7- E-type FHC

Comments? Experiences??

Bob Frisby

Boise, Idaho

'99 XK8

'7- E-type FHC

#11

Very interesting stuff. Obviously the quality/durability of the shock mounts themselves is an issue. But in addition to this, the springs apparently fatigue (?), resulting in lower ride height. I'm sure I'm not the first to think of using spacers to compensate for this. I was hoping that someone else had tried spacers, and could offer some advice as to thickness and material. Lacking any more info, I will try cutting spacers from white cutting-board material, probably about 3/8" thick or a little more. I plan to drill three holes in each spacer for the top-side studs. The spacer will then end up on top of the shock mount, adding to its total thickness.

Comments? Experiences??

Bob Frisby

Boise, Idaho

'99 XK8

'7- E-type FHC

Comments? Experiences??

Bob Frisby

Boise, Idaho

'99 XK8

'7- E-type FHC

l have never actually checked the full length of travel of the front shock absorbers but it needs to be remembered that a spacer at the top is eating into that travel.

The following users liked this post:

Superchargedxkr (03-12-2023)

#12

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)