Top Fluid Level Discussion

#41

The inflection of the fluid would not be so great if the tank was not tapered at the top. Thanks for your willingness to provide accurate information.

Well I just finished dinner and thought instead of beating the dog I'd beat the dead horse

Attached are pics showing the fluid level in the pump reservoir when the top is fully closed (that's the pic where the fluid is even with the top hash mark) and fully open (the fluid level is above the top hash mark). Ma! is the horse dead yet or should we keep beating this thing? Ah, it's great we have the freedom of expression---now let's go watch the Olympics.

Attached are pics showing the fluid level in the pump reservoir when the top is fully closed (that's the pic where the fluid is even with the top hash mark) and fully open (the fluid level is above the top hash mark). Ma! is the horse dead yet or should we keep beating this thing? Ah, it's great we have the freedom of expression---now let's go watch the Olympics.

#42

#43

Join Date: Oct 2007

Location: PHX some of the time

Posts: 117,683

Received 6,338 Likes

on

5,523 Posts

#44

Wait now...would not the temperature and humidity matter...as well as the elevation above sea level...

sorry... I couldn`t resist.

Seriously though...this is hands down the *BEST* forum on the internet. Whenever a post is made we can count on many rapid and helpful responses. It has helped me greatly a number of times and I appreciate everyone who contributes to the XK8/XKR forum! Thanks all!

sorry... I couldn`t resist.

Seriously though...this is hands down the *BEST* forum on the internet. Whenever a post is made we can count on many rapid and helpful responses. It has helped me greatly a number of times and I appreciate everyone who contributes to the XK8/XKR forum! Thanks all!

The following users liked this post:

Gus (08-02-2012)

#45

#46

#47

Norri,

So we were trying to drill down a little on "Double Acting Hydraulic Cylinders", like those used to raise and lower our convertible tops. We posted back and forth a couple times on rates of fluid flow.

If I understand you correctly, your view it that the flow rate of fluid into one port of such a cylinder will always be matched by an equal flow rate out the other port. I think I can demonstrate to you that it is somewhat different, that the flow rate on the side with the pushrod will always be less than the flow rate on the other side. (But you'll be the judge of whether I succeed.)

Here's one of the pictures you posted as a point of reference. To save a ton of keystrokes, I'll refer to the bottom fluid chamber in the picture, where the rod is, as the "R" side, and the top chamber as the "E" (empty, no rod) side.

So here goes. To begin I'll ask you to in your mind's eye erase the pushrod from the picture ... but not the piston, keep that there. And of course we plug the hole where the rod used to exit. Now we have a free-floating piston separating the E and R chambers. An easy, if impractical, case to think about: total fluid volume must be constant, so fluid in / out on the E side must be matched by fluid out / in on R side. I bet everybody (OK, almost everybody) would agree so far.

We can generalize a little. There's no requirement that the fluids in E and R be the same. One could be hydraulic fluid, the other a fine Anejo tequila, though this would be criminal. We could even use an incompressible solid that acts like a liquid ... a supply of tiny glass beads for example. Generalized this way we get to "volume of stuff out = volume of stuff in." The term "stuff" has replaced "fluid", and there's a reason for introducing this apparant side track.

Now: put the pushrod back in the picture. The constant-volume principle is still at work. Any fluid entering the E side must be matched by ... what? By an equal volume of "stuff" leaving the R side, counting everything that's leaving. And there are two things leaving; some volume of fluid, and some volume of pushrod. We can't ignore the volume of pushrod going out past the seal any more than we can ignore the volume of fluid going out the fluid port. It's the two added together that must equal the volume entering the E side. Total stuff in = total stuff out, not fluid in = fluid out. And so the R-side flow of fluid cannot equal, must always be less than, the E-side flow.

Two limiting cases are of interest. If the pushrod cross section is very small, it's contribution to total volume is too, and the flow rate in R will be nearly as large as that in E. On the other hand, if the pushrod is very thick, let's say nearly as thick as the tube it runs in, then fluid flow on the R side approaches zero. Nearly all the fluid flow on the E side is matched by the rod movement on the R side. (There's a practical limit to how thick the ram could be; we need to leave room for hydraulic fluid on the R side to push the piston back up when the time comes to do that.)

So that's how I see it: Total stuff in = total stuff out. Fluid flow on E side is always greater than flow on R side, and the thickness of the pushrod determines how much greater.

So: what say you about all this?

--------------------------

p.s. OK, so who gives a s**t? Not many, I'll bet, and that's why browsers have back buttons. As has been noted more than once, this has zero impact on the care and feeding of an XK8/R. But trying to figure things out is its own reward, and the next time I run into one of these dual-action thingies, I'll know how to think about it from the get go.

So we were trying to drill down a little on "Double Acting Hydraulic Cylinders", like those used to raise and lower our convertible tops. We posted back and forth a couple times on rates of fluid flow.

If I understand you correctly, your view it that the flow rate of fluid into one port of such a cylinder will always be matched by an equal flow rate out the other port. I think I can demonstrate to you that it is somewhat different, that the flow rate on the side with the pushrod will always be less than the flow rate on the other side. (But you'll be the judge of whether I succeed.)

Here's one of the pictures you posted as a point of reference. To save a ton of keystrokes, I'll refer to the bottom fluid chamber in the picture, where the rod is, as the "R" side, and the top chamber as the "E" (empty, no rod) side.

So here goes. To begin I'll ask you to in your mind's eye erase the pushrod from the picture ... but not the piston, keep that there. And of course we plug the hole where the rod used to exit. Now we have a free-floating piston separating the E and R chambers. An easy, if impractical, case to think about: total fluid volume must be constant, so fluid in / out on the E side must be matched by fluid out / in on R side. I bet everybody (OK, almost everybody) would agree so far.

We can generalize a little. There's no requirement that the fluids in E and R be the same. One could be hydraulic fluid, the other a fine Anejo tequila, though this would be criminal. We could even use an incompressible solid that acts like a liquid ... a supply of tiny glass beads for example. Generalized this way we get to "volume of stuff out = volume of stuff in." The term "stuff" has replaced "fluid", and there's a reason for introducing this apparant side track.

Now: put the pushrod back in the picture. The constant-volume principle is still at work. Any fluid entering the E side must be matched by ... what? By an equal volume of "stuff" leaving the R side, counting everything that's leaving. And there are two things leaving; some volume of fluid, and some volume of pushrod. We can't ignore the volume of pushrod going out past the seal any more than we can ignore the volume of fluid going out the fluid port. It's the two added together that must equal the volume entering the E side. Total stuff in = total stuff out, not fluid in = fluid out. And so the R-side flow of fluid cannot equal, must always be less than, the E-side flow.

Two limiting cases are of interest. If the pushrod cross section is very small, it's contribution to total volume is too, and the flow rate in R will be nearly as large as that in E. On the other hand, if the pushrod is very thick, let's say nearly as thick as the tube it runs in, then fluid flow on the R side approaches zero. Nearly all the fluid flow on the E side is matched by the rod movement on the R side. (There's a practical limit to how thick the ram could be; we need to leave room for hydraulic fluid on the R side to push the piston back up when the time comes to do that.)

So that's how I see it: Total stuff in = total stuff out. Fluid flow on E side is always greater than flow on R side, and the thickness of the pushrod determines how much greater.

So: what say you about all this?

--------------------------

p.s. OK, so who gives a s**t? Not many, I'll bet, and that's why browsers have back buttons. As has been noted more than once, this has zero impact on the care and feeding of an XK8/R. But trying to figure things out is its own reward, and the next time I run into one of these dual-action thingies, I'll know how to think about it from the get go.

Last edited by Dennis07; 08-03-2012 at 01:39 PM. Reason: spelling, duh

#48

Join Date: Oct 2007

Location: PHX some of the time

Posts: 117,683

Received 6,338 Likes

on

5,523 Posts

I saw were you were heading with that before you got there and was almost tempted to agree with you, however, we have the same pump delivering stuff to both equally sized ports.

This means when providing pressure to port E the cylinder will be able to move faster than in the other direction due to the lesser volume created by the rod being able to evacute through port R at the same rate of flow.

So total stuff in to or out of port E will be more than total stuff into or out of port R by an amount equal to the volume consumed by the rod.

The flow will be the same.

This means when providing pressure to port E the cylinder will be able to move faster than in the other direction due to the lesser volume created by the rod being able to evacute through port R at the same rate of flow.

So total stuff in to or out of port E will be more than total stuff into or out of port R by an amount equal to the volume consumed by the rod.

The flow will be the same.

The following users liked this post:

Gus (08-03-2012)

#49

The size of the ports plays no role in this at all. No pump was mentioned, nor need it be to see how this device must behave. We could have a pump pushing fluid into one port and the other port sending fluid out into a bucket; that would not change things either.

But enough. We can agree to see it differentlly, and the world will go on just fine I suppose.

Still ... if SteveInFrance is looking, I'd be interested in how he sees this.

But enough. We can agree to see it differentlly, and the world will go on just fine I suppose.

Still ... if SteveInFrance is looking, I'd be interested in how he sees this.

Last edited by Dennis07; 08-03-2012 at 08:16 PM.

#50

#51

An actual measurement

Ram rod dia = 0.8 cm Stroke ~18 cm

Volume of 2 rods = 2 x 0.4^2 x Pi x 18 = ~18 ccs which will be the difference in reservoir level.

Re the Norri/Dennis debate - if I may comment as one who uses hydraulics and pneumatics pretty regularly.

Both views are correct.(Give that man a Diplomat's medal)

However Norri, by talking of flow rate, has (literally) introduced another dimension, time.

Given that a pump had a perfectly constant flow rate regardless of pressure (which is not practically possible) then the velocity of the ram rod would be greater when retracting than extending because the pump would need to deliver less fluid (by the volume of the piston rod) and this would take less time (L/min).

In the real world this often doesn't happen because the effective area of the piston on the rod side is less by the area of the rod so to provide the same force on retraction requires a higher pressure than on extension.

In designing hydraulically actuated mechanisms it is always good practice to use a double acting ram with the 'power' stroke as extension to take advantage of the full piston area.

I'll go away now.

Ram rod dia = 0.8 cm Stroke ~18 cm

Volume of 2 rods = 2 x 0.4^2 x Pi x 18 = ~18 ccs which will be the difference in reservoir level.

Re the Norri/Dennis debate - if I may comment as one who uses hydraulics and pneumatics pretty regularly.

Both views are correct.(Give that man a Diplomat's medal)

However Norri, by talking of flow rate, has (literally) introduced another dimension, time.

Given that a pump had a perfectly constant flow rate regardless of pressure (which is not practically possible) then the velocity of the ram rod would be greater when retracting than extending because the pump would need to deliver less fluid (by the volume of the piston rod) and this would take less time (L/min).

In the real world this often doesn't happen because the effective area of the piston on the rod side is less by the area of the rod so to provide the same force on retraction requires a higher pressure than on extension.

In designing hydraulically actuated mechanisms it is always good practice to use a double acting ram with the 'power' stroke as extension to take advantage of the full piston area.

I'll go away now.

The following users liked this post:

Dennis07 (08-04-2012)

#52

Steve,

The UN called ...

That 18 CCs is the actual value for our cars? Great. If I measured it right, the two hash marks on the reservoir are about twice that far apart, so it seems they over did it. (Maybe the pump maker just puts two generic marks on there without thinking about particular cars that will use the pump?)

---------------

Anyway, to finish (??) ... Since our narratives get a little dense, I thought somebody might want to see the simple formulas for flow rates and total volume that apply. This is for the case of the piston/pushrod moving down in the picture in post #47 above. We use lower case e & r here instead of E & R used there, since here we need "R" as the familiar symbol for radius (I should have planned ahead).

So, for the:

- Flow rate into the e side (the change in e-side volume per unit time)

- Flow rate out of the r side (the change in r-side volume per unit time)

- Net flow into the cylinder (= the difference between these two)

- Total change in fluid held in the cylinder through a complete pushrod stroke ...

edit: corrected picture inserted; earlier one had error

Here Rc is the radius of the cylinder, Rp the radius of the pushrod, Vp is the velocity of the pushrod, and STROKEp is the length of the pushrod stroke.

If SteveInFrance wanders by, maybe he could double-check these please.

The UN called ...

That 18 CCs is the actual value for our cars? Great. If I measured it right, the two hash marks on the reservoir are about twice that far apart, so it seems they over did it. (Maybe the pump maker just puts two generic marks on there without thinking about particular cars that will use the pump?)

---------------

Anyway, to finish (??) ... Since our narratives get a little dense, I thought somebody might want to see the simple formulas for flow rates and total volume that apply. This is for the case of the piston/pushrod moving down in the picture in post #47 above. We use lower case e & r here instead of E & R used there, since here we need "R" as the familiar symbol for radius (I should have planned ahead).

So, for the:

- Flow rate into the e side (the change in e-side volume per unit time)

- Flow rate out of the r side (the change in r-side volume per unit time)

- Net flow into the cylinder (= the difference between these two)

- Total change in fluid held in the cylinder through a complete pushrod stroke ...

edit: corrected picture inserted; earlier one had error

Here Rc is the radius of the cylinder, Rp the radius of the pushrod, Vp is the velocity of the pushrod, and STROKEp is the length of the pushrod stroke.

If SteveInFrance wanders by, maybe he could double-check these please.

Last edited by Dennis07; 08-04-2012 at 01:09 PM.

#53

I have been watching this thread with some amusement. This horse has not only been beaten to death, but ground up and served in a French Restaurant. (sorry Steve)

I thought of an issue quite some time back and felt certain that someone would eventually bring it up, but I have yet to notice it. I don't know if this is a factor, and I am not so **** as to go out and do exhaustive tests to find out, partly because I feel certain that others will come up with differences of a tenth of a second or two and want to dispute my findings and I am not going to get that deeply involved in it.

I am not sure, but it is my general impression that the top lowers faster than it rises. I have always assumed that that could be due to the fact that in the raising direction, the pump must lift the weight of the top for the initial part of the operation, and then the weight of the top would give the pump some added help toward the end of the operation.

I was going to bring this up early on in the thread when the issue of flow came up, (In physics and engineering, in particular fluid dynamics and hydrometry, the volumetric flow rate, (also known as volume flow rate, rate of fluid flow or volume velocity) is the volume of fluid which passes through a given surface per unit time. source, Wiki)

which is a factor of time, as opposed to the initial part of the thread, which was about volume, but felt certain that someone else would get to it, and preferred to stay out of the fray.

Now that the issue of time has been brought up as well the fact is that the factor of time may very well be of more significance in the rate of flow than the physical space taken up by the rods.

I'll leave it to others to go out and do a series of tests to see if there is a time differential in the opening and closing operations.

I recall that some time back there were some fairly extensive tests done regarding the whole issue with the two methods to reduce the pressure in the system, one being the voltage reduction method and the other the pressure relief valve.

JagRepair.com - Jaguar Repair Information Resource

Well, that's all that I have to say about that, flow on.

I thought of an issue quite some time back and felt certain that someone would eventually bring it up, but I have yet to notice it. I don't know if this is a factor, and I am not so **** as to go out and do exhaustive tests to find out, partly because I feel certain that others will come up with differences of a tenth of a second or two and want to dispute my findings and I am not going to get that deeply involved in it.

I am not sure, but it is my general impression that the top lowers faster than it rises. I have always assumed that that could be due to the fact that in the raising direction, the pump must lift the weight of the top for the initial part of the operation, and then the weight of the top would give the pump some added help toward the end of the operation.

I was going to bring this up early on in the thread when the issue of flow came up, (In physics and engineering, in particular fluid dynamics and hydrometry, the volumetric flow rate, (also known as volume flow rate, rate of fluid flow or volume velocity) is the volume of fluid which passes through a given surface per unit time. source, Wiki)

which is a factor of time, as opposed to the initial part of the thread, which was about volume, but felt certain that someone else would get to it, and preferred to stay out of the fray.

Now that the issue of time has been brought up as well the fact is that the factor of time may very well be of more significance in the rate of flow than the physical space taken up by the rods.

I'll leave it to others to go out and do a series of tests to see if there is a time differential in the opening and closing operations.

I recall that some time back there were some fairly extensive tests done regarding the whole issue with the two methods to reduce the pressure in the system, one being the voltage reduction method and the other the pressure relief valve.

JagRepair.com - Jaguar Repair Information Resource

Well, that's all that I have to say about that, flow on.

#54

Kevin,

Definite 'Angels Dancing' thread this.

As I said in post #51 (is it that late already?) the retract time is theoretically but not practically quicker.

At the end of the top up sequence the 'pram top' assembly goes over centre to lock the hood and energy is stored by stretching the hood fabric.

On the way down this stored energy (as well as the assembly weight as you say) contributes to speeding up the process.

Anyway I'm off to a French restaurant not to eat horse but generally to wine + dine in good company so I'll bid you all a fond farewell for tonight.

Definite 'Angels Dancing' thread this.

As I said in post #51 (is it that late already?) the retract time is theoretically but not practically quicker.

At the end of the top up sequence the 'pram top' assembly goes over centre to lock the hood and energy is stored by stretching the hood fabric.

On the way down this stored energy (as well as the assembly weight as you say) contributes to speeding up the process.

Anyway I'm off to a French restaurant not to eat horse but generally to wine + dine in good company so I'll bid you all a fond farewell for tonight.

#55

Join Date: Oct 2007

Location: PHX some of the time

Posts: 117,683

Received 6,338 Likes

on

5,523 Posts

#56

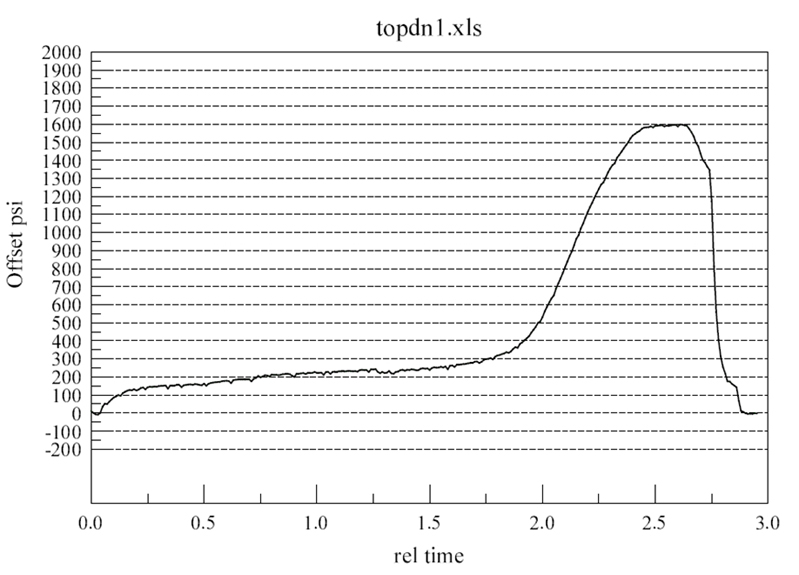

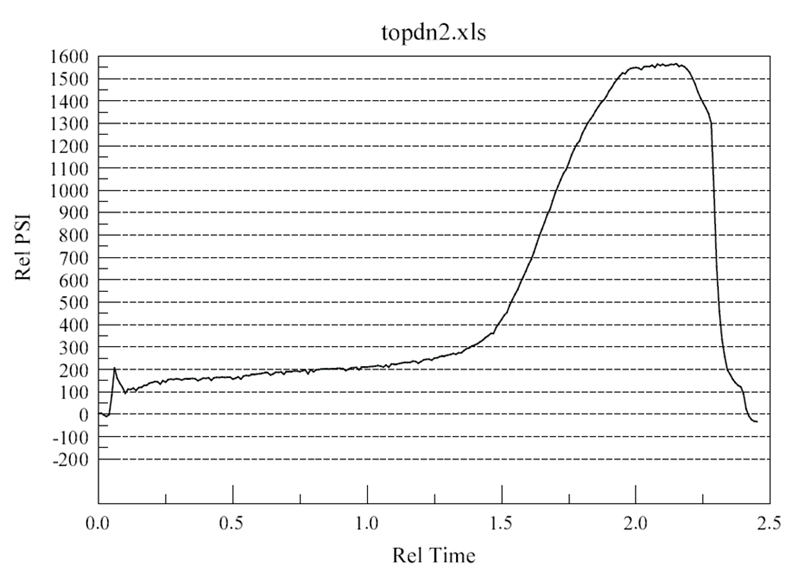

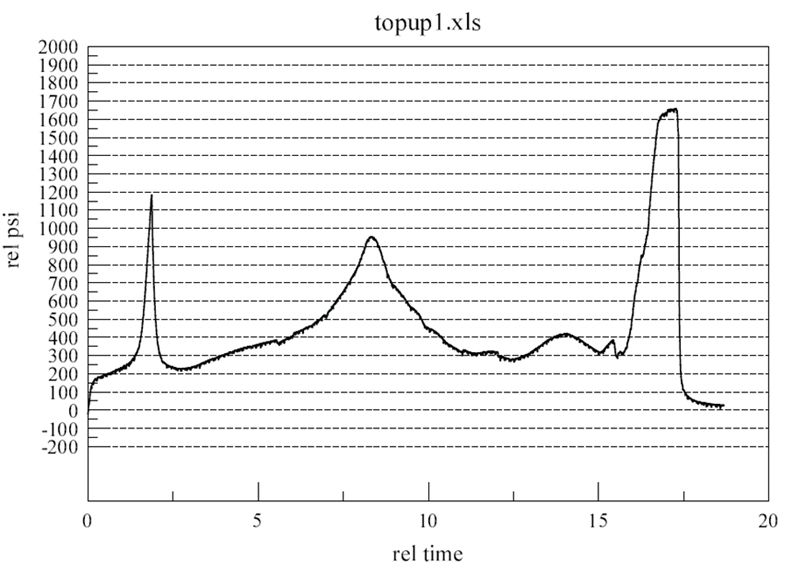

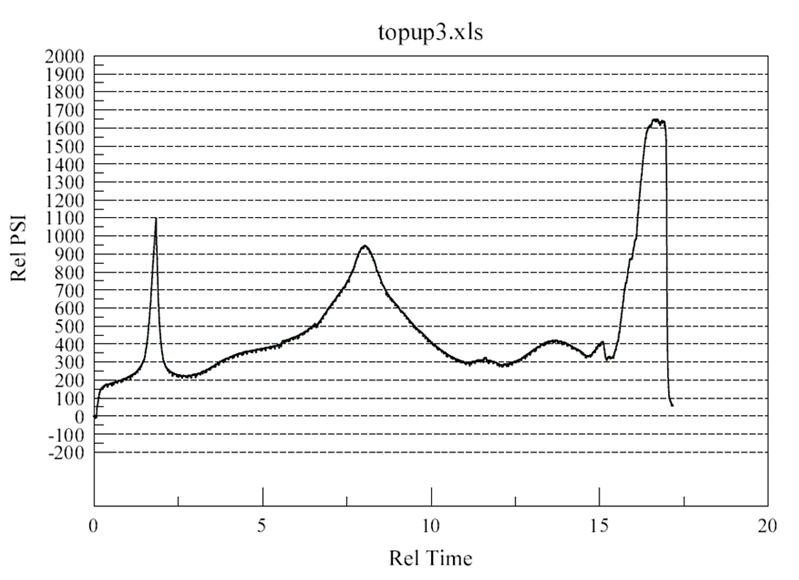

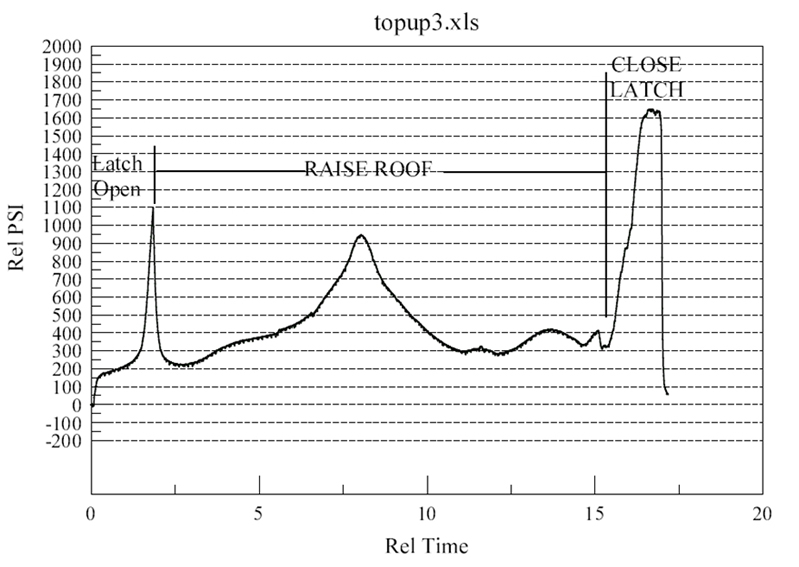

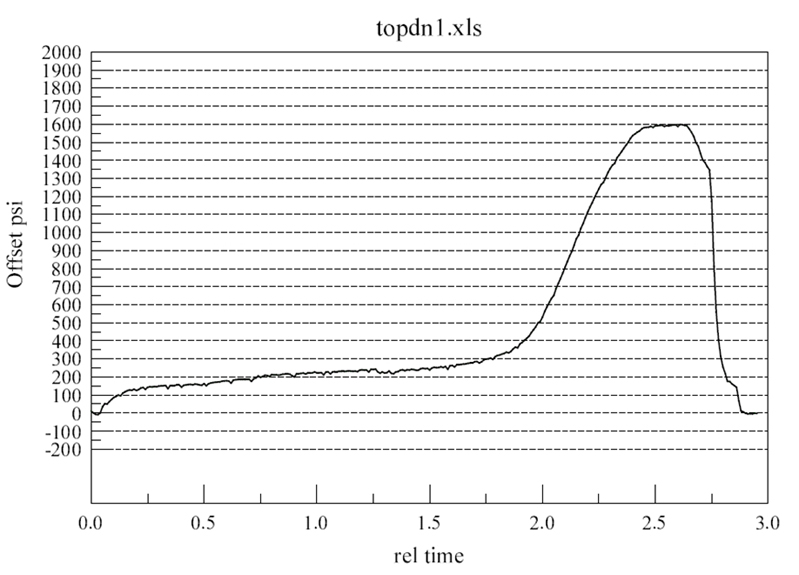

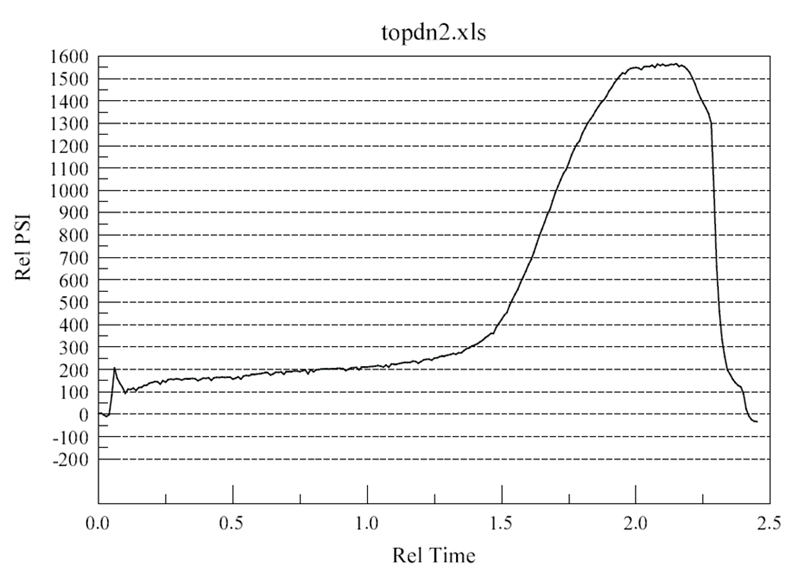

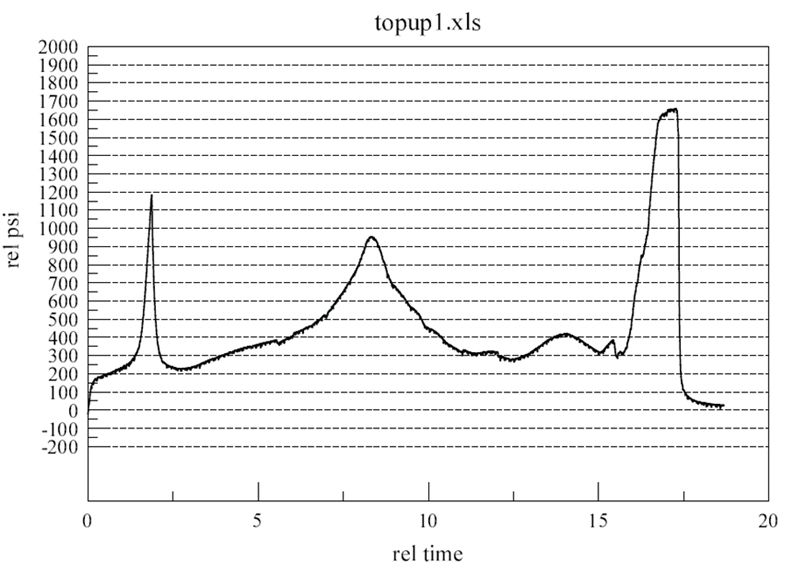

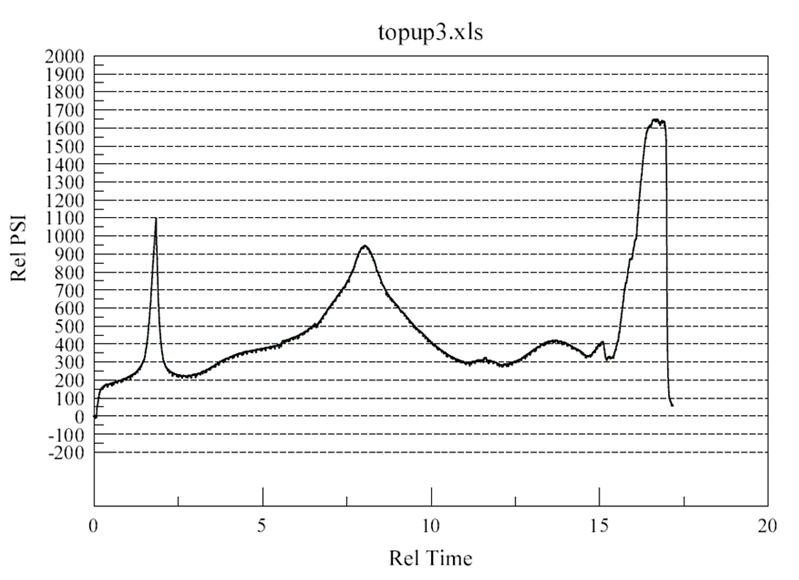

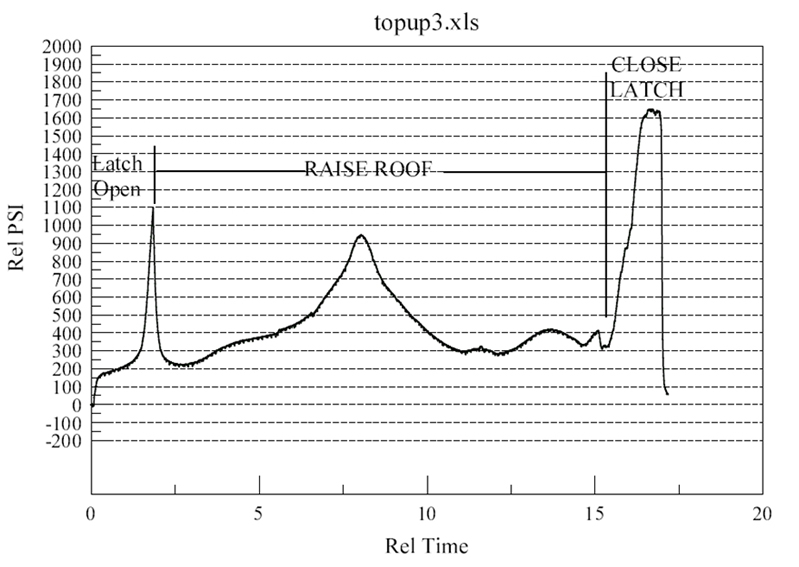

Steve, I think that if you look at the times for top up and top down under various pressure levels in this link, you will see some significant differences in time intervals, unless I am reading the graphs wrong, the bottom of the graph indicates seconds to complete the operation, and you will see very significant differences. I don't know exactly what each graph refers to, and I never delved in the minutia of the whole matter, but I am willing to bet that the time to complete the up and down sequences are not identical, under any circumstances, and that it should be obvious that the "flow rate" is based as much, if not more on the actual time to complete each sequence as the minor differences in volumes as a result of the displacement of the rods.

JagRepair.com - Jaguar Repair Information Resource

Charts and the process from Walt

JagRepair.com - Jaguar Repair Information Resource

Charts and the process from Walt

Last edited by Kevin D; 08-04-2012 at 04:32 PM.

#57

I agree. I totally love the discussion and the back-and-forth, and when and if the details become a tad cumbersome or argumentative I simply scroll down to the next post

Knowing all the while that should the need or interest arise I can always come back and dive into the minutiae. Lovin it, seriously

Knowing all the while that should the need or interest arise I can always come back and dive into the minutiae. Lovin it, seriously

#59

#60

Couldn't resist, huh?

I don't know if the pump makes about the same flow rate raising as lowering the top, but if it does ...

A given flow rate pumped into the pushrod side of the ram will move the piston faster than that same flow rate pumped into the other side. (Less volume to fill per unit travel, because the pushrod is there.)

Overall, the pump will have delivered SteveInFrance's 18 cc more fluid raising than lowering the top. So if the rates of flow are the same lowering the top as raising it, the unintuitive but clear result is than lowering top will be faster that raising it.

This might explain all or part of the faster top lowering.

I don't know if the pump makes about the same flow rate raising as lowering the top, but if it does ...

A given flow rate pumped into the pushrod side of the ram will move the piston faster than that same flow rate pumped into the other side. (Less volume to fill per unit travel, because the pushrod is there.)

Overall, the pump will have delivered SteveInFrance's 18 cc more fluid raising than lowering the top. So if the rates of flow are the same lowering the top as raising it, the unintuitive but clear result is than lowering top will be faster that raising it.

This might explain all or part of the faster top lowering.

Last edited by Dennis07; 08-06-2012 at 01:14 PM. Reason: clarity